Selecting High-Frequency Materials for Enhanced PCB Performance By Angie Brown, PCB Product Manager Epec Engineered Technologies

In the realm of Printed circuit boards (PCBs) design and fabrication, the selection of appropriate materials plays a pivotal role in determining the performance and reliability of the final product. As electronic devices continue to evolve, becoming faster and more complex, the need for materials that can support high-frequency applications has become more critical.

This article delves into the considerations and strategies for selecting high-frequency materials to enhance performance in PCB designs, focusing on high-performance FR4 materials and specialty laminates designed for signal integrity.

Understanding the Basics: FR4 and High-Frequency Materials

The standard material for PCB construction is FR4, a grade of flame-retardant fiberglass-reinforced epoxy laminate. Renowned for its versatility and cost-effectiveness, FR4 serves as the backbone for the majority of PCBs in various electronic devices. Its mechanical strength, electrical insulation, and thermal stability make it suitable for a wide array of applications. However, as the electronic industry progresses towards higher frequencies and more complex signal requirements, the limitations of standard FR4 materials become apparent. Specifically, its dielectric properties, which are adequate for low to moderate frequencies, may lead to signal degradation in high-frequency environments. This is where high-frequency PCB materials step in to bridge the gap.

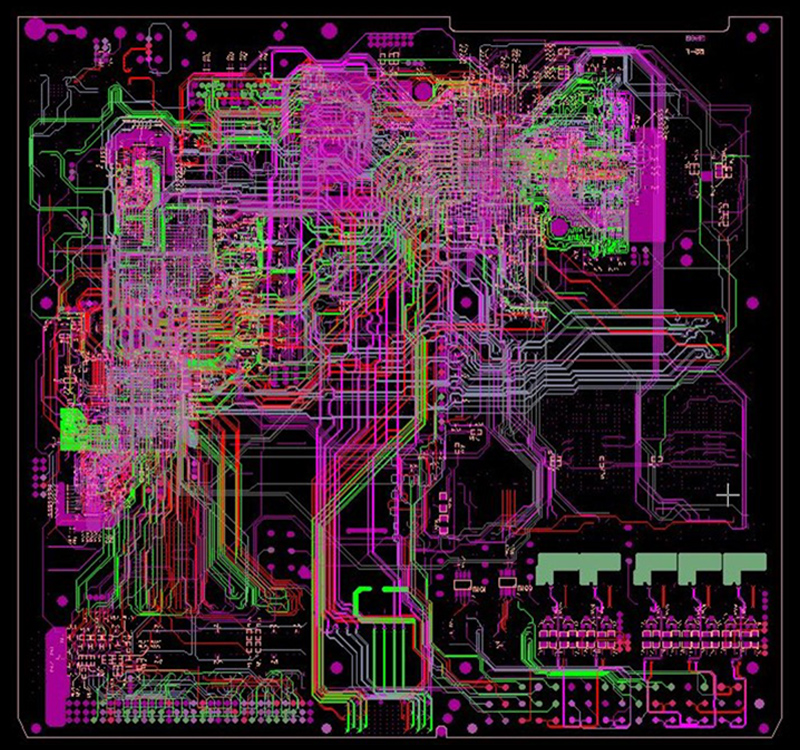

High-frequency PCB materials are meticulously engineered to address the challenges posed by high-speed and high-frequency circuits (Figure 1). Unlike standard FR4, these materials boast lower dielectric constants and dissipation factors, translating to reduced signal loss and superior performance in applications requiring precise signal integrity. This characteristic is particularly crucial for advanced technologies that operate in the GHz frequency range, such as 5G communications, advanced radar systems, and high-speed digital circuits.

Figure 1: A high-speed, densely populated, impedance-filled, PCB requires something other than FR4 to perform due to its designed-in features.

Figure 1: A high-speed, densely populated, impedance-filled, PCB requires something other than FR4 to perform due to its designed-in features.

Moreover, these specialized materials exhibit enhanced thermal performance to withstand the heat generated by high-speed operations, ensuring the reliability and longevity of the electronics. The transition to high-frequency materials is not merely a choice but a necessity for industries pushing the envelope of technology, where even minor improvements in material properties can yield significant advantages in performance and efficiency.

The evolution from FR4 to high-frequency materials underscores a broader trend in the electronics industry: the need for materials that can keep pace with the rapid advancements in technology. As PCB designers strive to achieve faster speeds, higher densities, and greater functionality, the selection of the right circuit board material becomes increasingly critical. High-frequency materials, with their superior electrical and thermal properties, offer a path forward, enabling the next generation of electronic devices to reach new heights of performance and reliability.

Significance of Dielectric Constant and Dissipation Factor

The dielectric constant (Dk) and dissipation factor (Df) are two critical parameters when selecting materials for high-frequency PCBs. The dielectric constant, a measure of a material's ability to store electrical energy, directly affects the signal speed and impedance of the PCB. On the other hand, the dissipation factor indicates the amount of signal loss as the electrical energy is converted into heat. For high-frequency applications, materials with a low dielectric constant and low dissipation factor are preferred to minimize signal loss and maintain signal integrity.

Transitioning to High-Performance FR4 and Specialty Materials

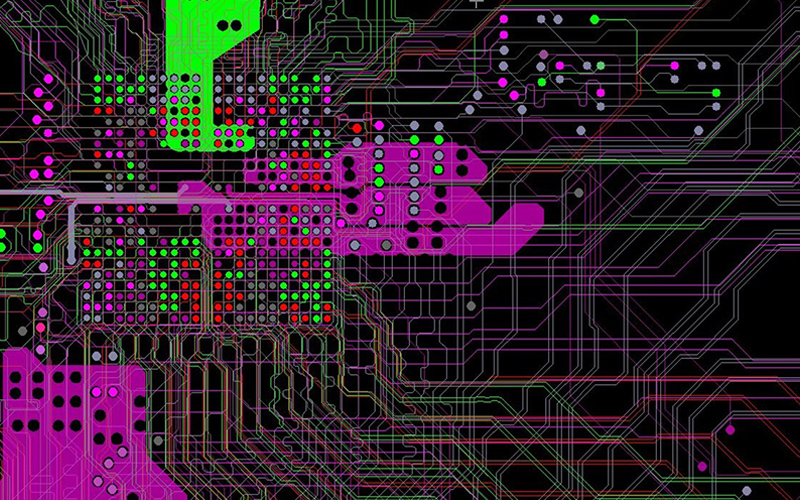

While standard FR4 materials have been the backbone of PCB fabrication, the industry has seen the emergence of high-performance FR4, and specialty materials tailored for high-frequency applications. These materials, such as Nelco 4000-13EP and Isola I-Speed, offer enhanced thermal and mechanical performance while maintaining the processing ease of traditional FR4. They are characterized by lower dielectric constants and dissipation factors, making them suitable for applications where signal integrity is critical (Figure 2).

Figure 2: A closer view of the BGA area and internal connections, requiring signal excellence.

Figure 2: A closer view of the BGA area and internal connections, requiring signal excellence.

For instances where FR4 materials fall short, especially in very high-speed or high-frequency circuits, designers must look towards materials specifically formulated for these challenges. Products like Rogers 3000 and 4000 series, Taconic RF35, and Arlon Cuclad offer significantly improved electrical properties over traditional materials. These high-frequency laminates are designed to support the demanding requirements of modern electronics, providing lower electrical losses, improved signal integrity, and higher thermal stability.

Tachyon® Laminate and Materials

For more than 100 years, Isola has been the industry leader in developing and manufacturing copper-clad laminate products used to fabricate advanced multilayer PCBs. They have an optimal balance between cost and performance when selecting base materials. Some of the key factors that microwave, and millimeter wave designers must consider when choosing a high-speed RF or microwave laminate include dielectric thickness, dielectric constant, dissipation factor, and maintaining tight tolerance within a batch as well as batch-to-batch.

The Tachyon® 100G laminate and prepreg materials by Isola are engineered for high-speed digital applications, capable of supporting data rates up to and beyond 100 Gb/s. These materials boast ultra-low loss characteristics and are designed with the highest thermal performance in mind, making them suitable for high layer count line cards and fine-pitch BGA applications. Their exceptional electrical properties are stable across a wide frequency and temperature range, offering a scalable solution for next-generation designs. Manufactured in Asia and North America, Tachyon® 100G products are recognized for their low moisture absorption, compatibility with HDI technology, and ability to undergo multiple lamination cycles.

Application-Specific Selection

Choosing the optimal material for a high-frequency PCB transcends a mere analysis of material properties; it requires a deep dive into the unique demands of the intended application. Beyond the basic electrical characteristics, considerations such as operating frequency, temperature range, environmental conditions, and mechanical stresses are pivotal in pinpointing the material that aligns perfectly with a project's goals. This multi-faceted approach ensures that the selected material not only supports the electrical requirements but also thrives under the specific operational conditions anticipated for the device.

For instance, automotive radar systems and the burgeoning infrastructure of 5G wireless networks place rigorous demands on material performance due to their operation within very high-frequency ranges. These applications necessitate materials with exceptionally low dielectric constants and dissipation factors, minimizing signal loss and latency to facilitate rapid, reliable communication and data transfer. Additionally, the chosen materials must exhibit robust thermal stability and resilience to environmental stresses, ensuring consistent performance and longevity in diverse and often challenging operating environments.

This tailored, application-specific selection process underscores the importance of a holistic view in material choice, combining an understanding of material science with the practical realities of the device's end use. By meticulously aligning material properties with application requirements, designers and engineers can significantly enhance the efficacy, reliability, and overall performance of high-frequency PCBs, paving the way for innovations that push the boundaries of current technology.

Challenges and Solutions in PCB Fabrication

Working with high-frequency materials presents unique challenges in PCB fabrication. These materials often require special handling and processing techniques to prevent damage and ensure high-quality results. For instance, materials with high Teflon content can be difficult to laminate due to Teflon's non-stick properties. PCB fabricators must employ specific surface treatments and adhesion promotion techniques to achieve reliable lamination.

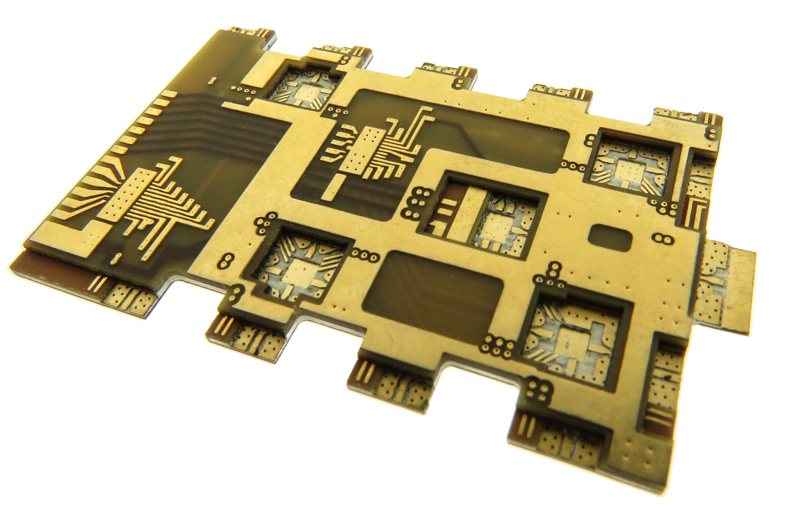

Also, the cost of high-frequency materials is significantly higher than standard FR4, prompting PCB designers and fabricators to seek cost-effective solutions without compromising performance. One strategy is the use of hybrid constructions (Figure 3), where high-frequency materials are used only in critical areas of the circuit board, while less expensive materials like standard FR4 are used elsewhere. This approach allows for the optimization of performance and cost, making high-frequency circuit boards more accessible for a wider range of applications.

Figure 3: Complex RF hybrid circuit board designed with cavities.

Figure 3: Complex RF hybrid circuit board designed with cavities.

Summary

The selection of high-frequency laminate materials for PCB design is a critical process that requires a thorough understanding of material properties, application requirements, and fabrication challenges. As electronic devices continue to push the boundaries of speed and complexity, the need for materials that can support these advancements becomes increasingly important.

By carefully selecting the appropriate high-frequency materials, PCB designers can enhance the performance of their circuit board, ensuring that they meet the stringent requirements of modern electronics. Whether through the use of high-performance FR4, specialty laminates, or hybrid constructions, the goal remains the same: to achieve the highest possible signal integrity and reliability in the final product.

Not Sure What High-Frequency Laminate Is Best For Your Neededs?

Our team of experienced engineers is here to help you design and manufacture a high-quality circuit board solution to get you ready to move into production.

Request a Quote Request Design Support