How RF Trends in Electronics Are Impacting Connectors By Mark Stanley, RF Product Manager Epec Engineered Technologies

When it comes to electronics, technology is moving forward at a rapid pace and component manufacturers are trying to keep up. Devices are becoming smaller and more complex, whether it is a smartphone, medical imaging device, or a remote sensor accessing military satellite systems. At the same time, the devices still need to be rugged enough to withstand enormous amounts of wear and tear while offering unhindered data transmission and collection capabilities.

With the new requirements of electronic product manufacturing, connector components have to be redesigned for these devices. The redesign is not always easy, as the connectors themselves must be micro-miniature and sub-miniature in nature. In addition, OEM companies need more customizable design options for their products for specific applications. Manufacturers are striving to meet these changing RF trend demands by offering flexible cables with reliable interfaces, trusted connections, and portability features.

When Space and Performance Matters

To account for smaller electronic devices, RF/Microwave product trends are moving toward lower profile components. Devices still have complex assemblies, yet the size and weight requirements have been significantly lowered to allow for more portability features.

Based on the type of plug that is desired for the connector, many OEM companies are searching for microwave assemblies that provide higher speed interfaces up to 67 GHz utilizing 1.85mm connectors capable of high mating cycles.

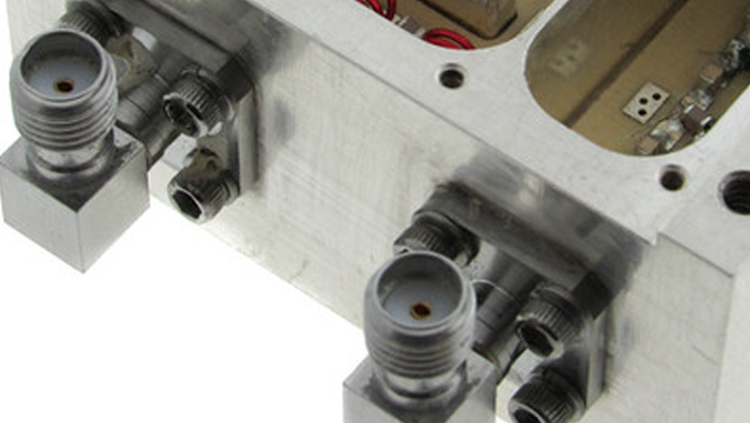

Figure 1: Example of microwave connector used in various RF filter designs.

Figure 1: Example of microwave connector used in various RF filter designs.

Higher Frequency Demands for Greater Data Transmission

Device systems are now trending toward fiber optic and microwave cables due to the tremendous amounts of data being transmitted and received. These complex systems are moving from traditional single digit GHz performance levels to frequency requirements above 40 GHz.

RF connectors for microwave cables are now focusing on providing smaller mechanical components offering higher packaging densities while still maintaining a superior performance level. Manufacturers are now focusing on providing high-speed coaxial RF connectors to meet telecommunications technology demands, while keeping in mind to still meet the MIL-STD 348B standard RF dimensional requirements for military interfaces.

Variable Connection and Disconnection Capabilities

Military system applications sometimes require RF cables that can disconnect on command. Due to this requirement, connectors can experience problems with disconnecting at the wrong times, or having pin-mating issues. Connector options need to be more flexible to meet these applications without affecting the higher frequency and performance needs of the system.

Changing the number and position of pins can help to alleviate the issues of having a sure mating while allowing for the cable to disconnect when desired. However, operating systems have moved toward needing higher performance of frequencies of 28 GHz or more. Present keying schemes have only allowed for up to 8 GHz frequencies.

Keyed coaxial connectors are being introduced for electronics that allow for 18 GHz performance while providing keyed position options. This set up minimizes mating issues while providing a more reliable connection to handle systems that experience high shock and vibration in varied environments.

Newer Design Capabilities to Reduce Compression

When looking at an old coaxial cable, the first thing to notice is the rigid design of the cable at the attached point of the connector. Terminated cables may experience compression when being twisted and turned, affecting the durability of the connector and causing a negative impact to connector performance.

This RF trend requires connector designs to be more flexible. Manufacturers are looking at connectors supplying a sure mating with a failure-proof coupling nut while offering cable plugs that allow for different polarizations.

Figure 2: Field Replaceable Bulkhead RF filter mating with coupling nut.

Figure 2: Field Replaceable Bulkhead RF filter mating with coupling nut.

As Technology Advances, More Customized Connector Solutions Are Required

The forward pace of technology is expected to go faster as our data transmission needs increase. Connectors need to be able to rise up to this challenge without lagging behind in either performance or operational options. RF connectors need to be designed in the correct configuration desired for the specific product or application, whether it will be used for satellite devices, mobile communication or even in electronic warfare applications.

Need Help With A Custom RF Filter and Cable Assembly?

Our custom RF filters and cable assemblies are a great fit when an off-the-shelf solution isn’t meeting the specification of your applications.

Request a Quote Request Design Support