Designing for IPC Class III - Meeting Aerospace-Grade PCB Standards By Angie Brown, PCB Product Manager Epec Engineered Technologies

In electronics manufacturing, terms like “high-reliability” and “aerospace-grade” are often used interchangeably, even though they describe very different levels of control, testing, and accountability. For engineers, program managers, and supply chain teams, misunderstanding these terms can lead to compliance gaps, unexpected cost increases, or qualification delays late in a program. Clarifying what IPC Class III truly guarantees, and what aerospace programs typically require beyond it, is essential when specifying, sourcing, or qualifying printed circuit boards for critical applications.

In this article, we will review and compare the differences between IPC Class III printed circuit boards (PCBs) and the standards typically referred to as “Aerospace-Grade” PCBs. The key point is that aerospace grade is not a single IPC class, it is a stack of requirements, often built on IPC Class III (or 3A) plus additional military, space, and quality-system controls.

IPC Class III (High-Reliability Electronics)

IPC Class III represents the highest reliability classification defined by IPC standards and is governed primarily by IPC-A-600, IPC-6012 (Figure 1), and IPC-A-610. This class is intended for continuous operation in critical systems where failure is not acceptable, and where long service life and exposure to harsh environments are expected.

From an application standpoint, Class III PCBs are commonly associated with life-support systems, military electronics, and flight-critical commercial avionics. The standard assumes that assemblies will be subjected to demanding mechanical, thermal, and electrical conditions over extended periods of time.

Technically, IPC Class III imposes tighter requirements than Class 2 across several fabrication and workmanship areas. These include larger minimum annular rings on most plated through holes, thicker copper plating on hole walls, typically 25 microns or greater, and stricter acceptance criteria for solder joints. Solder connections must exhibit full wetting, smooth fillets, and minimal voiding. Conductor spacing is more tightly controlled, and internal defects such as delamination, voids, and cracks are extremely limited. In addition, Class III requires 100 percent electrical netlist testing to verify connectivity.

Despite its rigor, IPC Class III has important limitations when viewed through an aerospace lens. The standard does not mandate aerospace-specific materials, does not require full lot traceability back to raw laminate batches, and does not impose environmental or radiation testing. It also does not enforce aerospace quality management systems. As a result, while Class III defines how well a PCB is built, it does not fully address how it is controlled, documented, or validated for aerospace programs.

IPC-6012 Performance Classes Overview

| Aspect | Class 1 | Class 2 | Class 3 |

|---|---|---|---|

| Official Description | General Electronic Products | Dedicated Service Electronic Products | High-Reliability Electronic Products |

| Primary Goal | Functionality | Long-term reliability | Continuous operation, failure not acceptable |

| Typical Use Cases | Toys, consumer gadgets, novelty electronics | Industrial controls, automotive, telecom | Aerospace, medical life-support, defense |

| Operating Environment | Benign, intermittent | Moderate, continuous | Harsh, continuous, critical |

| Tolerance for Defects | Highest | Moderate | Lowest |

| Inspection Level | Sampling | Increased inspection | 100% inspection of critical features |

| Cost | Lowest | Medium | Highest |

Figure 1: IPC standards are regulated into different classes to meet certain manufacturing standards, with class III being the highest standard.

What “Aerospace-Grade” Means in The PCB Industry

The term “aerospace-grade PCB” does not refer to a single standard. Instead, it is an industry shorthand for circuit boards that meet IPC Class 3 or Class 3A requirements plus additional aerospace and military controls. These additional requirements typically extend well beyond fabrication workmanship and into quality systems, documentation, testing, and long-term traceability.

Common governing standards associated with aerospace-grade PCBs include IPC-6012 Class 3A, which adds avionics-specific requirements to Class III, MIL-PRF-31032 for military and aerospace PCB performance, AS9100 for aerospace quality management systems, and NASA-STD-8739 for spaceflight workmanship.

Depending on the application, aerospace designs may also reference IPC-2221 or IPC-2222 with aerospace constraints, as well as RTCA DO-254 for airborne electronic hardware.

Key Differences Between IPC Class III and Aerospace-Grade PCBs

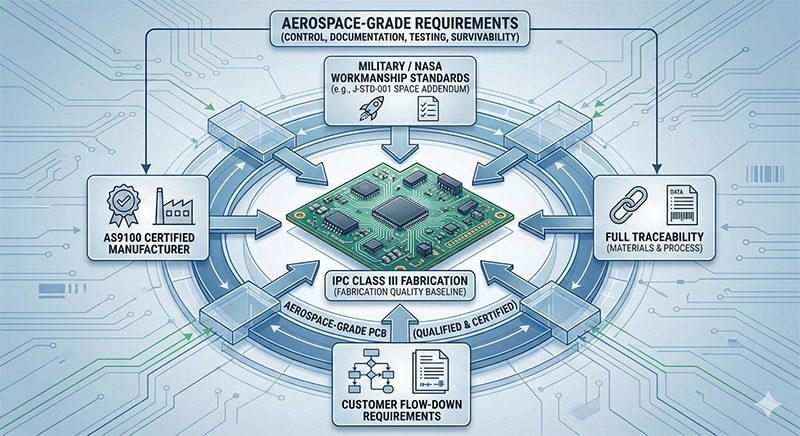

When viewed side by side (Figure 2), the distinction between IPC Class III and aerospace-grade PCBs becomes clearer. IPC Class III provides high reliability, but aerospace-grade requirements push reliability into the mission-critical category. While both typically rely on Class 3 fabrication, aerospace programs often mandate Class 3A for avionics.

IPC Class 3 vs. Mil-Spec PCB Comparison

| Category | IPC Class 3 | Mil-Spec (Military PCB Standards) |

|---|---|---|

| Governing Standard | IPC-A-600 / IPC-6012 Class 3 | MIL-PRF-31032, MIL-STD-6012, plus program-specific specs |

| Primary Use | High-reliability commercial & industrial electronics | Defense, aerospace, weapons, space, mission-critical systems |

| Reliability Expectation | Continuous operation, failure not acceptable | Zero-tolerance mindset; must survive extreme conditions |

| Inspection Level | 100% inspection of critical features | 100% inspection + government audits & traceability |

| Plated Through Hole (PTH) Wall Thickness | ≥ 25 µm (≈ 1 mil) | ≥ 25 µm minimum, often higher per contract |

| Annular Ring (Internal/External) | Larger than Class 2; tightly controlled | Equal or tighter than IPC Class 3 |

| Hole Wall Voids | Very limited; strict acceptance criteria | Minimal to none; stricter rejection thresholds |

| Conductor Spacing & Width | Tight tolerances | Same or tighter, often dictated by program requirements |

| Material Requirements | High-Tg FR-4, polyimide, etc. | Approved materials list only (QPL/QML) |

| Thermal Cycling | Required | More severe cycling and shock testing |

| Environmental Testing | Limited to IPC requirements | Vibration, shock, humidity, salt fog, altitude |

| Traceability | Manufacturer lot traceability | Full material, process, and inspection traceability |

| Documentation | IPC compliance documentation | Extensive documentation + government |

| Failure Allowance | Extremely low | Practically zero |

| Cost | High | Very high (often 2‐5× Class 3) |

| Lead Time | Moderate | Long (due to testing, audits, approvals) |

Figure 2: When comparing IPC standards to mil-spec Class III may be enough.

Quality systems are another major difference. IPC Class III requires IPC compliance, whereas aerospace-grade manufacturing almost always requires AS9100 certification. Material control also diverges, as Class III allows standard FR-4 materials, while aerospace-grade programs frequently specify aerospace-qualified laminates with batch-level control.

Traceability under IPC Class III is limited, whereas aerospace-grade PCBs require full lot and serial traceability. Inspection methods expand beyond visual and electrical testing to include X-ray analysis and microsectioning. Process controls are tighter as well, with frozen and audited processes replacing standard IPC controls.

Environmental and radiation testing, which are not required under IPC Class III, are often mandatory for aerospace and space systems. Documentation requirements also increase significantly, shifting from a standard certificate of conformance to detailed build books, travelers, and first article inspection reports.

IPC Class 3A and Why It Matters

IPC Class 3A is a critical distinction within aerospace electronics. It is an avionics-specific enhancement of Class III and introduces stricter requirements for annular rings, plating thickness, hole integrity, and internal defect acceptance. These tighter criteria are often mandatory for flight-critical avionics programs.

Many aerospace customers explicitly call out “IPC-6012 Class 3A plus AS9100” in their requirements. Because documentation and verification play such a large role in these programs, it is essential to understand expectations during the quotation phase. In many cases, documentation effort rivals’ fabrication effort in terms of cost and schedule impact.

How Aerospace Requirements Are Applied in Practice

In practical terms, IPC Class III alone does not automatically qualify a PCB as aerospace-grade. Aerospace-grade (Figure 3) typically implies IPC Class 3 or 3A fabrication performed by an AS9100-certified manufacturer, compliance with military or NASA workmanship standards, full material and process traceability, and customer-specific flow-down requirements.

Put simply, IPC Class III defines how good the PCB is from a fabrication standpoint. Aerospace-grade defines how controlled, documented, tested, and survivable the PCB must be within a regulated program environment.

Figure 3: Many products fall within Class III but require a domestic-sensitive build. High-reliability items that meet the standard are common in all product classes.

Figure 3: Many products fall within Class III but require a domestic-sensitive build. High-reliability items that meet the standard are common in all product classes.

Typical Use Cases

IPC Class III is commonly used for industrial controls, medical devices, and high-reliability commercial electronics where long life and low failure rates are required but full aerospace governance is not. Aerospace-grade PCBs are reserved for applications such as flight-critical avionics, spacecraft and satellites, defense systems, and missile guidance or radar platforms, where failure has severe consequences.

IPC Class III and 3A in Context

IPC Class III and Class 3A are fundamentally fabrication and workmanship standards. Class III represents the highest IPC reliability class, with tight visual, dimensional, and defect acceptance criteria intended for harsh environments.

Class 3A builds on this by tailoring requirements specifically for avionics, with even stricter reliability expectations. While these standards are frequently used in aerospace applications, they do not by themselves constitute aerospace certification.

MIL-PRF-31032 and Military Performance Requirements

MIL-PRF-31032 is the U.S. Department of Defense performance specification governing PCB processing and validation for military and aerospace use. It typically uses IPC-6012 Class III or 3A as a baseline but adds significant performance and quality consistency requirements.

Circuit boards manufactured under this specification often undergo destructive and non-destructive testing, including microsection analysis, plating adhesion testing, and thermal shock. Environmental stress testing such as thermal cycling, vibration testing, and HALT or HASS may also be required. Full traceability to raw material batches is mandatory, often with record retention measured in decades. Cleanliness standards and tightly controlled manufacturing environments are also enforced to reduce risks such as electrochemical migration.

Manufacturers must be formally certified to supply PCBs under MIL-PRF-31032 for defense and aerospace programs.

Aerospace Quality Systems and AS9100

AS9100 is the aerospace quality management system standard that builds on ISO 9001 with additional requirements focused on risk management, traceability, corrective action, and supplier control. Many aerospace OEMs require AS9100 certification as a baseline for doing business.

AS9100 ensures documented control of manufacturing processes, complete audit trails from design through delivery, structured non-conformance reporting, and formal supplier management. While IPC compliance can exist without AS9100, most aerospace programs cannot be satisfied without it.

How the Standards Stack Together

In a typical aerospace PCB program, multiple standards work together rather than in isolation. Fabrication quality is governed by IPC-6012 Class III or 3A, while assembly workmanship follows IPC-A-610 Class III or 3A. Performance validation is addressed through MIL-PRF-31032, and quality management is enforced through AS9100. Space programs may add NASA workmanship standards, while environmental and EMI testing often reference MIL-STD-810 and MIL-STD-461.

In practical terms, an aerospace-grade PCB is the result of IPC Class III or 3A fabrication combined with military performance specifications, AS9100 quality systems, and program-specific testing and documentation.

What Aerospace Customers Expect

An aerospace PCB order typically includes a certificate of conformance indicating compliance with applicable IPC and military standards, first article inspection reports, and full traceability documentation linking finished circuit boards to raw materials and manufacturing processes. Environmental test reports for vibration, thermal cycling, or stress screening are common, as are manufacturing travelers and complete audit trails.

Why Aerospace PCBs Cost More

Aerospace PCBs carry higher costs because they demand far more than fabrication alone. Extensive documentation and long-term record keeping are required, along with both automated and manual inspections such as microsectioning and X-ray analysis. Batch traceability, AS9100 and military audits, and rigorous test programs all add effort, time, and overhead compared to commercial PCB production.

Aerospace PCBs involve significantly more work than commercial printed circuit boards, not because they are merely built better, but because they are built under far tighter controls.

Summary

IPC Class III defines the highest IPC level for PCB fabrication quality and workmanship, but it addresses only how a circuit board is built. On its own, even Class 3A does not meet the broader expectations typically implied by “aerospace-grade.”

Aerospace-grade PCBs are defined by a layered set of requirements that extend beyond IPC, combining Class III or 3A fabrication with military and space performance specifications, certified aerospace quality systems, and program-specific testing and documentation.

The real distinction lies in control and accountability. Aerospace programs demand tightly governed processes, full material traceability, expanded inspection and environmental testing, and extensive deliverables to support long-term reliability, compliance, and auditability.

Looking for an Aerospace-Grade PCB?

Our team of experienced engineers can help from design through production while manufacturing to these strict standards with program-specific testing and documentation.

Request a Quote Request Design Support