How Rigid-Flex PCB Design Configurations are Advancing By Paul Tome, Product Manager Flex & Rigid-Flex Epec Engineered Technologies

Advancements in rigid-flex circuit board materials, stack-ups, and constructions now allow for a wide variety of advanced design configurations. These options create significant opportunities to achieve higher levels of both design integration and packaging density within a given design.

This article introduces and discusses the benefits and applications of some of the more common advanced rigid-flex constructions that are becoming more and more popular in the electronics industry.

The Future of Flexible Circuits

There are many new designs being manufactured with substantially higher flex layer counts. Some more prevalent designs include those with blind and buried via structures, integrated ZIF connections, and even designs with components mounted into both the flexible areas and the rigid sections.

Some rigid-flex printed circuit board (PCB) designs may have flex areas that require shielding for Electromagnetic Interference (EMI) or Radio Frequency (RF) considerations. There are also designs that have varying thicknesses between the different rigid areas as well as asymmetrical constructions.

This article covers some of the more common types of configurations and combinations that have been generating interest among OEMs. However, there are many additional configurations and combinations available for flex and rigid-flex circuit board stack-ups. The more advanced constructions covered here include odd layer count constructions, asymmetrical constructions, varying flex layer count designs, integrated ZIF connections, blind and buried vias, air gap flex layer constructions, multiple rigid area thicknesses, and shielded flex layers.

Standard Rigid-Flex PCB Constructions

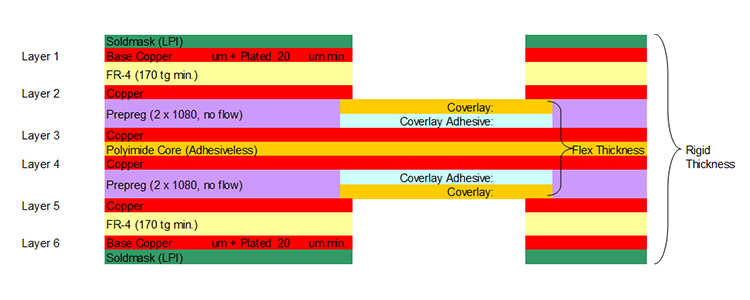

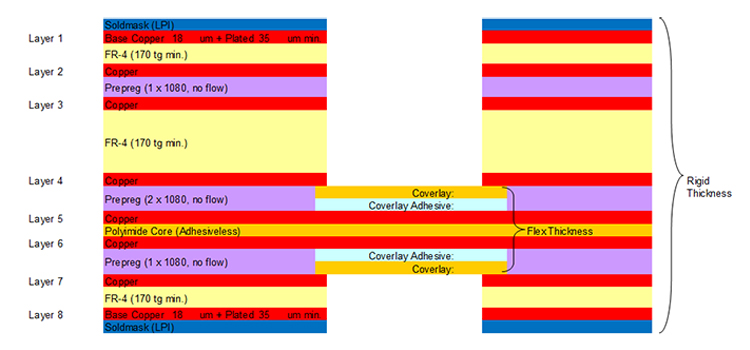

Figure 1 is an example of what is considered a standard rigid-flex PCB construction. This will act as a baseline to build upon for later examples. Generally, a standard rigid-flex PCB design has a symmetrical construction. This type of symmetrical design also allows for impedance control.

As shown in figure 1, the flex layers are in the center of the construction with even layer counts in both the rigid and the flex areas. In the two thicker areas, which are the rigid areas, there is an even layer count. In this example there are six layers but that can vary anywhere from four to sixteen layers or more. The key element in this design is that the flexible layers are located in the center of the construction.

Figure 1: Example of a standard 6-layer rigid-flex construction.

Figure 1: Example of a standard 6-layer rigid-flex construction.

Rigid-Flex PCB Constructions with Odd Layer Counts

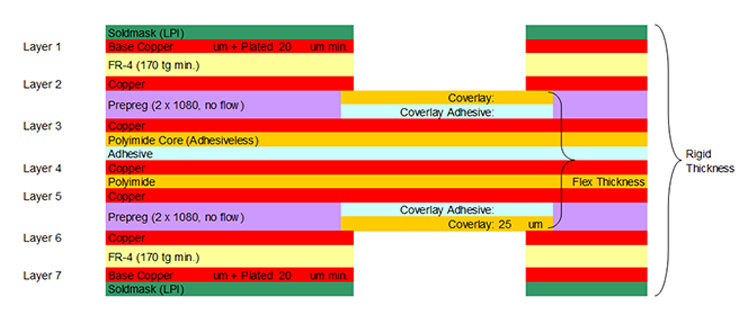

Figure 2 displays an example of an odd layer count construction. Most Engineers are familiar with rigid board design where even layer counts are a requirement. Although an odd layer count is a lesser known design, it is manufacturable and has its own set of benefits.

Figure 2: Example of an odd layer count rigid-flex construction.

Figure 2: Example of an odd layer count rigid-flex construction.

Figure 2 shows a seven-layer rigid board with three flexible circuit layers. This odd layer construction is primarily used for designs that require two-sided shielding in the flex areas which is mostly driven by stripline impedance control. Some designs may have RF and EMI considerations. The ground / signal / ground construction is contained within the three layers of flex. It can also allow for a large number of interconnects between rigid sections.

The stack-up example illustrated in Figure 3 is more simplistic. This rigid-flex construction has been designed with five layers in the rigid area and only one layer of flex for part numbers that have a minimal number of rigid to rigid interconnects. It also provides a high degree of flexibility and reduces costs.

Figure 3: Example of a 5-layer rigid-flex construction.

Figure 3: Example of a 5-layer rigid-flex construction.

Odd layer counts constructions, as shown in the previous two examples, apply to both the flex and rigid areas and are independent of each other. You can have an even layer count on one side and an odd layer count on the other end; if the design requires it. The primary advantage is that it minimizes the flex area thickness which provides improved flexibility, increased mechanical bending capabilities, and as a result improved mechanical bend reliability.

Bend reliability and constructions are compliant with IPC 2223C which ensures that the parts have both short-term and long-term reliability. Lastly, to a certain degree, odd layer counts can help reduce the cost of the design by minimizing the total number of flex layers specifically required in the design.

Asymmetrical Rigid-Flex PCB Constructions

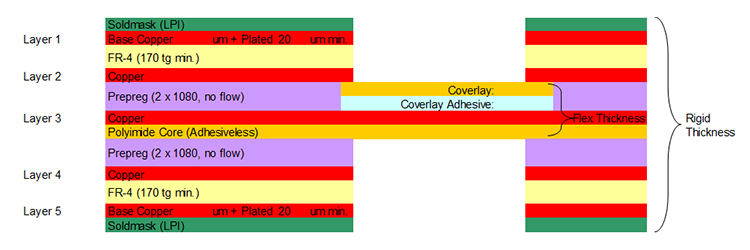

The next rigid-flex PCB construction is asymmetrical designs. The applications for an asymmetrical construction are typically driven by some very complex impedance requirements where there are widely varying dielectric thickness requirements within the design. These can also be caused by blind via constructions where the asymmetrical design construction allows the blind via aspect ratio to be reduced which, in turn, improves the manufacturability and reliability of parts.

Given that it is an unbalanced build, there may be some warp and twist that occurs within the assembly array. This may require a hold down fixture to allow the assembly arrays to be transported through the assembly process.

Figure 4 is an example of an eight-layer rigid-flex PCB asymmetrical construction. The flex layers are no longer located in the center of the design, instead they are shifted down towards the bottom. This type of stack-up is in a still a manufacturable configuration. There are no major manufacturing concerns aside from some warp and twist that may be induced in the assembly array.

Figure 4: Example of an asymmetrical rigid-flex circuit board construction.

Figure 4: Example of an asymmetrical rigid-flex circuit board construction.

Varying Flex Layer Count

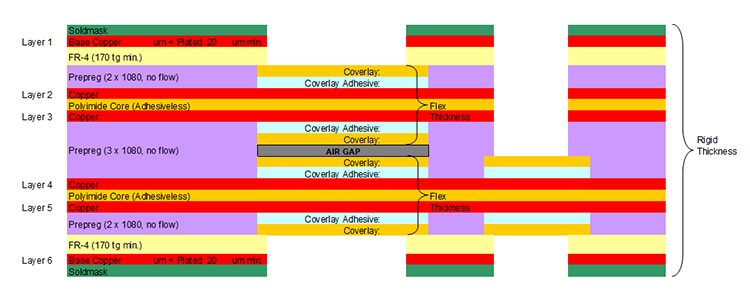

Another type of construction that is seen on a regular basis is where the flex layer count varies between rigid sections. For example, if you had three rigid sections you might have three or four flex layers joining the first and second rigid sections, but only one or two layers joining the second to the third. There are a variety of configurations available for this type of construction, but it is recommended to utilize an air-gap flex layer construction with this type of design to best meet IPC 2223C design guidelines.

Figure 5 shows an example of varying flex layer count. The first and second rigid sections have four layers of flex between them but the second and third rigid layers have only two layers of flex. Layers 2 and 3 are flex and although they do extend into the rigid section for routing purposes, they do not transcend between the two sections. The primary advantage of this is in the reduced flex section, given that the number of interconnects does not require additional layers, the reduction down to only two flex layers significantly improves the bend capabilities of this type of construction.

Figure 5: Example rigid-flex PCB designed with varying flex layer counts.

Figure 5: Example rigid-flex PCB designed with varying flex layer counts.

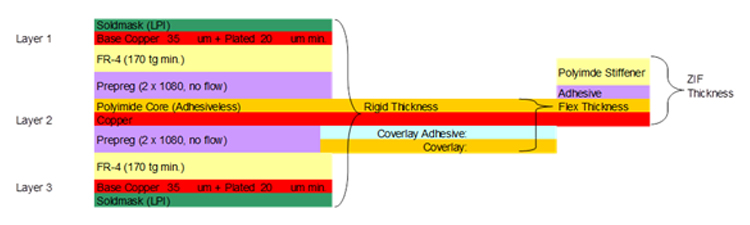

Integrated ZIF Tail Constructions

Another very common rigid-flex circuit board stack-up is the integration of a ZIF tail integrated into the rigid-flex. This, in turn, eliminates the need for the ZIF connector to be mounted onto the rigid board and eliminates the need to have a separate flex circuit. This type of construction reduces the real estate requirements in the rigid area. If the part is a high-density design (where real estate is at a premium) or if it is a very thin design where the height requirements of a ZIF could not be incorporated.

This type of construction also has an element of improved reliability through the elimination of a connector in the rigid section and its associated points of interconnect. There are a very wide variety of configurations available.

Figure 6: Example rigid-flex PCB with an integrated ZIF tail construction.

Figure 6: Example rigid-flex PCB with an integrated ZIF tail construction.

Figure 6 is an example of a very straightforward three-layer PCB integrated ZIF tail construction. The ZIF tail extends off to the right, this has the additional polyimide stiffener required to achieve the specific thickness in the ZIF finger contact area that is required by the ZIF connector.

This configuration can also be combined with multiple layers of flex; two, three, or even four layers. Four layers would be the maximum practical limit as it can become difficult to meet the ZIF thickness requirement. It’s most common to see one and two-layer flex configurations.

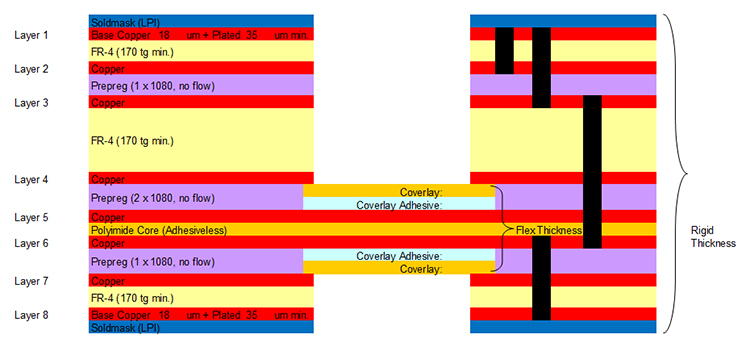

Rigid-Flex Circuits with Blind Vias & Buried Vias

The next type of rigid-flex PCB construction utilizes blind vias and buried vias. The applications are very similar to that of rigid circuit boards. It is typically driven by high-density BGA applications that require via-in-pad. This type of construction may also necessitate an asymmetrical construction if the blind vias are required to have an interconnect to the flexible circuit layers.

The configurations may be limited by the number of sequential lamination cycles that the designs require. Multi-layer rigid-flex PCBs can only accommodate a limited number of lamination cycles before the dimensional tolerances of the materials and the manufacturing methods prevent the layers from being effectively registered to one another so there are some limitations. Just as in rigid PCBs, for via-in-pad applications, via fill and capping is available.

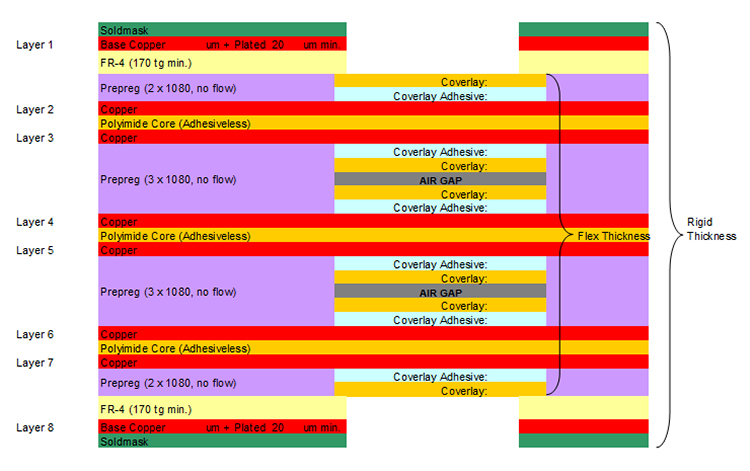

Figure 7 shows an example of a construction utilizing blind and buried vias. The blind and buried vias are shown in black in this stack up. There is a blind via that goes from the first to the second layers, a buried via from Layer 3 to Layer 7. Lastly, a blind via coming up from the bottom from Layer 8 to layer 7. This example is a symmetrical construction where the flex layers were centered in the material stack up.

Figure 7: Example rigid-flex PCB designed with blind and buried vias.

Figure 7: Example rigid-flex PCB designed with blind and buried vias.

Flexible Circuit with Air Gap Constructions

An air gap construction has the flex layers configured as separate independent pairs. One of the primary advantages is substantially improved flexibility of the flex section. This applies only to designs that have more than two layers of flex and is the preferred construction method for four or more flex layers due to the fact it allows the design to meet IPC 2223C guidelines. This type of construction results in no flexible adhesives present within the rigid areas which ensures the reliability of the via structure and provides the highest degree of reliability both at component assembly and long-term operation of the design.

Figure 8: Example rigid-flex PCB designed with an air gap structure in the flex regions.

Figure 8: Example rigid-flex PCB designed with an air gap structure in the flex regions.

Figure 8 shows six flex layers all configured with air gaps. Each flex pair has coverlay on both sides, then there is a small air gap. On the next pair, there is the same construction with two flex layer coverlays on both sides and so on, down to the third pair - this is considered a preferred configuration.

If this design was attempted with all six layers bonded together, it would not meet IPC 2223C. There would likely be some very significant via reliability issues and the flexibility of the flex section would be limited, almost to the point of not being functional.

Multiple Rigid Area Thickness Construction

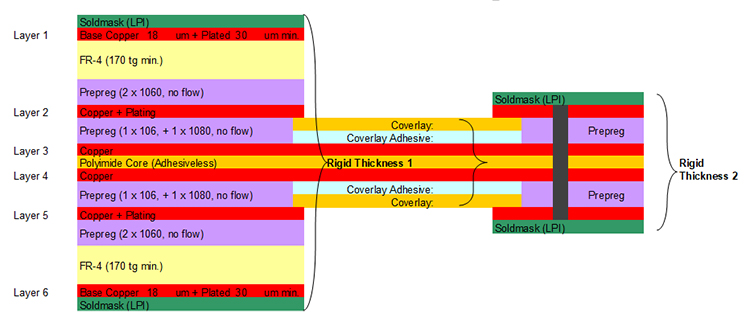

Having a part with multiple rigid area thicknesses is a very complex type of construction. While they can be manufactured, it is strongly recommended, where possible, that you review alternative options with your supplier. In this type of construction, you are practically limited to two rigid area thicknesses as a maximum. There may also be limitations as to what the rigid thicknesses can be due to the materials required for the construction. Ultimately, this is a costly type of stackup as it is analogous to manufacturing two boards to get one.

Figure 9: Example of multiple rigid area thickness construction.

Figure 9: Example of multiple rigid area thickness construction.

Figure 9 shows an example where the left-side rigid section is substantially thicker than the right-side section. There are plated holes and vias in both sections (although they're not shown in the left-hand section). The thinner section will have some limitations to its finished thickness as there must be a degree of commonality in the materials. The prepreg thicknesses need to be the same on the left side as on the right side. If there was an additional core on the right side, then it would have to be mirrored on the left side.

Ultimately, the part will first be manufactured as a four-layer construction. This would encompass layers two through five, run all the way through to the end of the manufacturing process (drilling, plating, surface finish, solder mask, electrical test, etc.) but would not include creating the outer profile. The design would then be taken virtually back to the beginning of the process where layers one and six would be added and then run all the way through the process again, after which the final outer profile would be added. It is a very expensive process but there are some applications that demanded it. There are potential design alternatives that can still meet the design requirements and will likely be less costly.

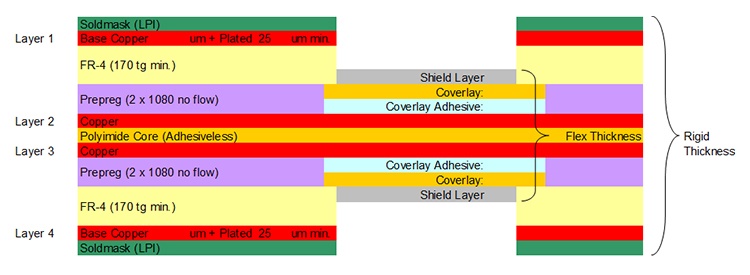

Shielded Flex Layers Construction

This last type of construction requires EMI or RF shielded flex sections. In this case rather than copper layers, it utilizes specialized films that were developed specifically for shielding of flex circuits. The more common brand names that we use are Tatsuta from Japan and APlus from China. These films allow for very effective EMI and RF shielding without the added cost of copper layers and allow for the benefits of reduced cost and a thinner flex construction for improved flexibility.

Figure 10: Example of a shielded flex layers construction.

Figure 10: Example of a shielded flex layers construction.

The flex area coverlays have multiple selective openings exposing the ground circuit. The films have an electrically conductive adhesive so once laminated, the adhesive extends into the coverlay openings and bonds on to the exposed ground thus grounding out the shield layers.

Figure 10 shows an example of four-layer design with two layers of flex. In the flex area only, you can see the shield layers laminated to the external side of the coverlay. Again, this is a more cost-effective solution than adding additional copper layers and it substantially increases the flexibility and mechanical bend capabilities of the flex layer.

Summary

The combination of today's rigid-flex PCB and flex circuit technology has created a very wide variety of constructions that can add a significant amount of functionality, design integration, and overall packaging reduction to a design. Most of the specific constructions that we have reviewed in this technical article can also be combined together to create an almost endless number of flex and rigid-flex circuit board configurations.

* This article was originally published in the June 2018 issue of PCD&F and is reprinted with permission.

Need Help With A Rigid-Flex PCB Design?

Our team of experienced engineers is here to help you design and manufacture a high reliability rigid-flex circuit board solution.

Request a Quote Request Design Support