PCB Plug Via Process

Epec offers a variety of printed circuit board manufacturing solutions for Plug Via Process requirements. Whether you require vias flooded with mask, selective plugging in BGA areas, conductive and non-conductive epoxy fill, copper filled, or fully pluged and via-in-pad, we have you covered.

Our experienced engineering team will help you to get your product to market faster, while eliminating delays and quality issues. Check out this blog post, PCB Vias - Everything You Need To Know.

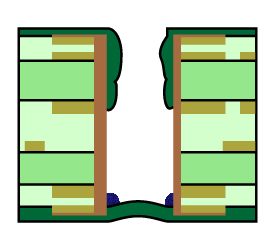

Primary LPI Solder Mask Tenting Vias

In tenting vias, no apertures are supplied on the mask data layer. The solder mask covers the via pads and tents hole. No surface finish is applied to the via barrel. For this process it is possible for entrapment to occur.

In the past, tenting of vias with Dry Film Soldermask was a standard offering. Due to the limitations on feature size resolution and high thickness for SMT applications of the Dry Film Masks, this process is not readily available. Assemblers may require plugged vias due to vacuum draw or to prevent paste wicking into vias.

This process is not advised for long term reliability. Many printed circuit board designs are seen with vias tented via primary mask. This could be a result of a lack of reliability data.

Pros:

The pros to primary LPI solder mask tenting vias is it is only a one step application.

Cons:

Via tenting cannot be guaranteed with LPI mask. There are three common methods of applying LPI mask. Curtain, Spray and Screen coating. Curtain and Spray coating cannot ensure that the via is tented both sides. Screen coatings ability to tent is limited by the hole size, surface tension of the liquid mask, and board thickness.

If a via is not tented on both sides, chemical entrapment from surface finish preclean lines is probable. All the finishes will be subject to a micro-etch process. The micro-etchant that gets trapped in the capped via will crystallize rapidly causing copper sulfate crystals. Over time, these crystals can cause long term reliability issues. In the case on ENIG finish, the gold and small area of exposed copper near the cap could form a galvanic cell, accelerating the etch process.

See our blog post titled Why Is Via Tenting Required On A PCB? for additional information.

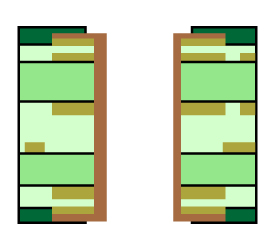

Vias Not Covered

If vias are not covered, they are exposed and the surface finish is applied to via barrel. This is standard process in printed circuit board fabrication.

Pros:

The via barrels are covered with surface finish metal. This allows circuit board testing access available from both sides of the board.

Cons:

It is possible for wicking of solder paste to get into the via. In the case of BGA rework, paste loss due to wicking into the via is a result of the localized thermal energy causing the LPI solder mask to lift on the short distance between the ball and via capture pads. This is not a concern at first pass assembly.

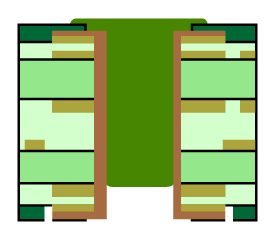

Button Print

In the process, vias are tented on one side by a secondary solder mask application. The surface finish is applied to the via barrel prior to button print.

This process was developed to allow a rework able, reliable via interconnect.

Pros:

The via barrels are covered with the surface finish metal. Test access is only available from one side of the board. This is rework able as solder wicking is not a concern. Button print vias are a standard industry process in fabricating printed circuit boards.

Cons:

This can cause perceived mask height issues at the time of assembly. The industry maximum height of soldermask over copper has been reduced over the years from 0.004" down to 0.002". This may require an additional mask application process, post surface finish application. This process is not recommended for OSP or Tin finish and the depth of mask cannot be controlled.

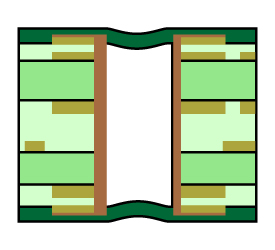

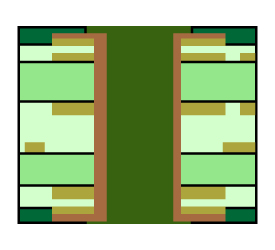

Plugged Via

In the plugged vias process, vias are plugged with solder mask or some other non conductive media. LPI mask is then applied over plug. During the plugged vias process, no surface finish is applied to via barrel.

This process was developed as a modification from the LPI tent to guarantee that 100% of the vias are fully tented.

Learn about Via-in-Pad Plugging or Plated Process and the Effect on PCB Hole Sizes.

Pros:

In plugged vias, 100% of the required vias are tented.

Cons:

For plugged vias, additional process steps are required during fabrication. No surface finish is applied to the via and the via size is restrictive. The control of rate of rise during curing is critical to ensure 100% of volatiles are evacuated. Failure to control this can lead to soldermask smearing the surface during the assembly reflow process.

Active Pad

In the active pad process, vias are plugged with a conductive or non-conductive media, then planarized and plated over.

This process allows the use of via capture pads as SMT pads. This is advised for via in pad applications only.

Pros:

For active pad vias, this reduces the routing issues on external circuit layers and minimizes inductance.

Cons:

During the active pad process, additional process steps are required in addition to a dual plating processes. The extra plating processes have a negative effect on the minimum feature size capable on the external circuit layers. This process is not advised in conjunction with PTFE substrates.

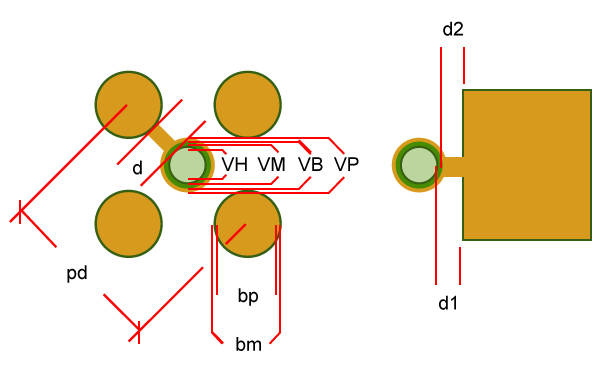

BGA (Ball Grid Array) Soldermask Design Guidelines

| Pitch | |||||

|---|---|---|---|---|---|

| Feature | Symbol | 1.27mm/50mils | 1.00mm/0.3937mils | 0.8mm/0.031496 | Discrete |

| BGA Pad | bp | 24 | 19 | 14 | |

| BGA Mask (Cu defined) | bm | bp+5 (4 min) | bp+5 (4 min) | bp+5 (4 min) | pad+5 (4 min) |

| BGA Pad Diagonal Distance | pd | 70.71 | 55.67 | 44.54 | |

| Via Pad | VP | 22-25 | 22 | 20 | |

| Via Hole | VH | 10-12 | 10 | 8-10 | |

| Via Mask | VM | VH+5 (4 min) | VH+5 (4 min) | VH+5 (4 min) | |

| BGA Mask Dam | d | 14.35-12.35 min | 9.33-8.33 | 7.27-5.27 | |

| Via Button Print | VB | VH+15 (10 min) | VH+15 (10 min) | VH+15 (10 min) | |

| d1 | 4 min | ||||

| d2 | 10 min | ||||

* Based on 0.062 thick board, non solder mask defined BGA pads and plastic BGA packages.

* Cu defined pad infers no mask will be present on the capture pad.

Need Help with Plugged Vias?

Discover the right PCB solution faster with Epec. From fully plugged vias to via-in-pad technology, our engineering expertise ensures a faster, reliable path to market for your product. Don't compromise on quality. Consult our engineering team today!

Understand the purpose of via plugging, Why Should you Fill or Plug a Circuit Board Via?

Request a Quote Request Design Support Request More Information