PCB Data Requirements & Fabrication Instructions

The purpose of this page is to define the minimum data set required for Epec Engineered Technologies to tool and manufacture a printed circuit board. These requirements apply to rigid circuit board orders and are intended to eliminate avoidable delays during engineering review and production release.

The minimum data package is divided into two primary categories:

Supplying both categories completely allows engineering to review, tool, and release the order efficiently.

At a Glance: PCB Data Requirements

- Minimum printed circuit board data and fabrication instructions required to place a rigid PCB order without production delays.

- By providing complete board data, fabrication notes, and technical contacts upfront, designers enable Epec’s engineering team to generate tooling accurately and move projects efficiently into production.

- Clear, approved data formats help reduce rework, revision cycles, and schedule risk.

Printed Circuit Board Data

Printed circuit board data includes all electronic files needed to define the board geometry, copper features, and hole structures. Providing approved and complete formats expedites order entry and reduces the likelihood of engineering questions or data revisions.

Note: Any data formats not listed on this page require review and approval by Epec before release to production.

See our blog post on PCB Fabrication Data File Requirements for more information.

Gerber Data (Accepted Formats)

Gerber files define the PCB image layers and are required for fabrication. Accepted formats include:

- RS-274D with a complete, separate aperture list

- RS-274X (preferred), with embedded apertures

- Gerber files with a full aperture list including all D-codes

- DXF files, accepted in limited cases after conversion and approval

- ODB++ files supplied as a single archive containing all board and drill data

Incomplete aperture definitions or unapproved formats may require manual editing, increasing the risk of delay or error.

Drill Data

Drill information is required to define plated and non-plated holes. Accepted formats include:

- Excellon 1

- Excellon 2

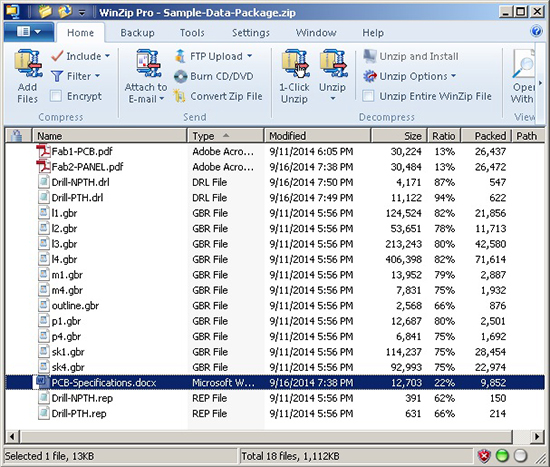

Example of a Complete PCB Data Package

Example of a Complete PCB Data Package

Netlist Data (Recommended)

Netlist data is not mandatory but is strongly recommended. A netlist enables direct comparison between the generated manufacturing database and the intended electrical design. When discrepancies are found, engineering reports the issues for correction, often resulting in data revision before production.

Netlists are critical for identifying opens and shorts and for supporting electrical testing. IPC-356 ASCII format is preferred and is typically readily available from the PCB designer.

See our blog post on What is a PCB Netlist and Why do You Need It for more information.

Printed Circuit Board Fabrication Instructions

Fabrication instructions communicate how the PCB is to be built. These notes should be clearly presented with the quote request and include all information required to tool and manufacture the part.

Slot and Hole Sizes

All slot and hole requirements must be defined so engineering can accurately process machining and drilling operations and noted as plated or non-plated.

Board Outline

The board outline should be supplied at a 1:1 scale and include all cutouts, dimensions, and tolerances. Hole-to-edge dimensions and X/Y coordinate locations help ensure accurate drill placement relative to the finished profile.

Finished Copper Weights

Finished copper weights must be specified for all internal and external layers. Balanced copper construction, for example, matching weights on paired internal layers, can improve manufacturability, reduce lead time, and in some cases lower cost.

Finished Board Thickness

The finished board thickness must be specified along with tolerances and measurement criteria. Industry-standard thickness tolerance is ±10%. For example, a nominal thickness of 0.062 mils ±0.006 mils, results in a finished range from 0.056 mils to 0.068 mils.

Where the thickness is measured (over metal, solder mask, laminate, or a combination) should be identified when thickness is critical, as this affects stack-up material selection.

Surface Finish Options

Common surface finishes include:

- HASL (Hot Air Solder Level, non-RoHS)

- ENIG (Electroless Nickel Immersion Gold)

- Immersion Silver

- OSP (Organic Solderability Preservative)

- Lead-Free HASL

- Immersion Tin

See our article on Printed Circuit Board Surface Finishes: Advantages and Disadvantages for more information.

Soldermask Requirements

Soldermask requirements should specify color and texture. Mask can be supplied in matte or gloss finishes using the four most common colors:

- Green

- Blue

- White

- Red

Additional colors may require engineering review, added processing time, and potential minimum order quantity considerations. See our blog post on Circuit Board Solder Mask - What to Use and What Not to Use for more information.

Silkscreen Requirements

Silkscreen color should be specified. Most silkscreens use UV-cured, RoHS-compliant inks. Common colors include:

- White

- Yellow

- Black

Alternate colors may affect cost and processing time.

Technical Contact Information

Providing a technical contact is critical for new or revised parts, as engineering or production questions may arise. Email and phone contact information helps minimize delays. Because Epec operates on a 24/7 production schedule, alternate contacts for nights and weekends can further reduce downtime.

Additional Requirements

Any special processing requirements should be clearly documented on fabrication drawings, including:

- Controlled impedance

- Specific dielectric requirements

- Plugged vias or via-in-pad processes

- Blind and buried vias

- Special considerations for surface finishes

- Selective surface finishes

- Counterbores, countersinks, or milling

Fabrication Instructions and Panelization

Fabrication drawings should be supplied in a clean, legible format. Gerber-format fabrication drawings are preferred, though other formats may be accepted. Array and panel configurations should define how like parts are grouped and connected with waste material.

Score and tab-routing details depend on material Tg, thickness, and copper placement. Engineering assistance is available through Epec’s free manufacturability review process to resolve these details efficiently.

See our blog post on Creating Standard PCB Fabrication Notes for more information.

Data Requirements & Deliverables for PCB Design Projects

Information Required to Quote and Perform PCB Design

To generate an accurate PCB design quote and ensure efficient execution, Epec requests detailed project information, including:

- Project overview and end-use environment

- Schematic files or netlists, when available

- Preferred CAD system (supported platforms include Cadence Allegro, Mentor PADS/Xpedition, and Altium)

- Preliminary bill of materials with part numbers and data sheets

- PCB specifications such as size, layer count, materials, thickness, copper weight, surface finish, and soldermask color

- Design rules, constraints, and identification of critical nets

- Signal and power integrity considerations

- Compliance and regulatory requirements

- Test, validation, and inspection needs

- Project timeline and milestones

Deliverables from Epec Upon Project Completion

Upon completion of a PCB design project, Epec provides a comprehensive set of deliverables, including:

- Fully annotated schematic diagrams in editable and PDF formats

- Complete PCB layout files suitable for fabrication and assembly

- Finalized bill of materials, if required

- A comprehensive DFM report from PCB manufacturing engineers

- Custom libraries, footprints, or databases developed during the project

By providing the above information and understanding what deliverables you can expect, we can work together to ensure a successful and efficient PCB design process. Contact Epec today to discuss your project and get started on your PCB design quote!

Frequently Asked Questions

Quick Links

- What is the minimum data required to place a PCB order?

- Are Gerber files always required?

- Is supplying a netlist mandatory?

- Why are fabrication notes important?

- What thickness tolerance is typical for PCBs?

- Why does Epec request technical contact information?

What is the minimum data required to place a PCB order?

At minimum, Epec requires complete printed circuit board data and fabrication instructions to generate tooling and release the board to production.

Are Gerber files always required?

Yes, Gerber data in approved formats is required. RS-274X is preferred because apertures are embedded.

Is supplying a netlist mandatory?

A netlist is not required but is highly recommended due to its role in validating electrical accuracy and supporting testing.

Why are fabrication notes important?

Fabrication notes communicate how the board is to be built and prevent delays caused by missing or unclear production requirements.

What thickness tolerance is typical for PCBs?

Industry-standard finished thickness tolerance is ±10%, though designers should specify measurement criteria when thickness is critical.

Why does Epec request technical contact information?

Having a technical contact allows engineering or production questions to be resolved quickly, reducing manufacturing delays.

Ready To Take Your PCB Project From Concept to Production?

Providing complete PCB data and clearly defined fabrication instructions helps ensure a smooth transition from quote to production. By aligning requirements upfront, Epec Engineered Technologies supports efficient engineering review, accurate tooling generation, and reliable PCB manufacturing. Get started and make your project a success with Epec Engineered Technologies.

Request a Quote Request Design Support Request More Information