Effective Ways To Reduce Your CNC Machining Costs

CNC machining costs will always vary depending on many different factors, including the length of time required to complete the project, materials specified, as well as the type of machine used, such as 3- and 5-axis machines.

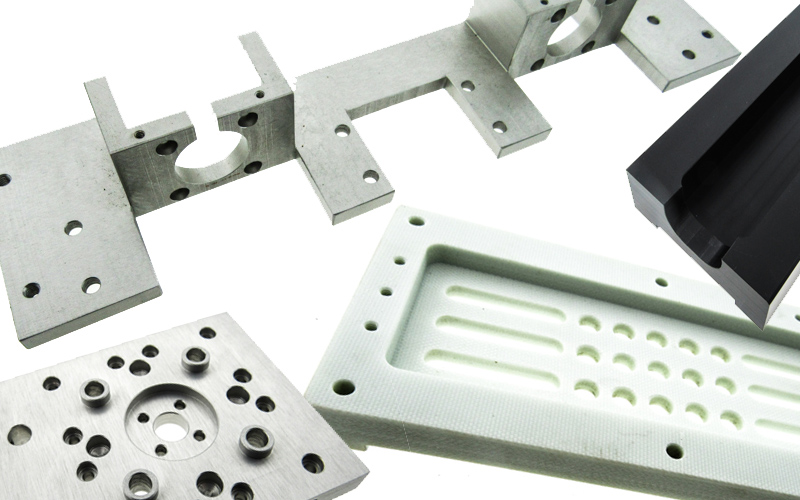

CNC machining is an integral part of many industries, getting the tools and parts you need with an accuracy that is difficult to achieve. Businesses are often looking for ways to trim their budgets; reducing CNC machining costs is no exception. If you are interested in CNC machining cost reduction, you need to understand the factors that impact the cost of CNC parts — machining time, start-up costs, material costs, and more.

In this webinar we review some of the biggest factors that can affect your CNC machining costs and specific ways to help you reduce costs on your CNC machined parts.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareCheck Out the Full Q&A

We have compiled all the questions submitted at the conclusion of this webinar into a readable format available on our blog.

Webinar Agenda:

- Overview of the Biggest Factors Affecting CNC Costs

- Understanding the Dual-Sourcing Model

- The 5 Specific Ways to Reduce Costs

- What Criteria Affect Costing and Delivery