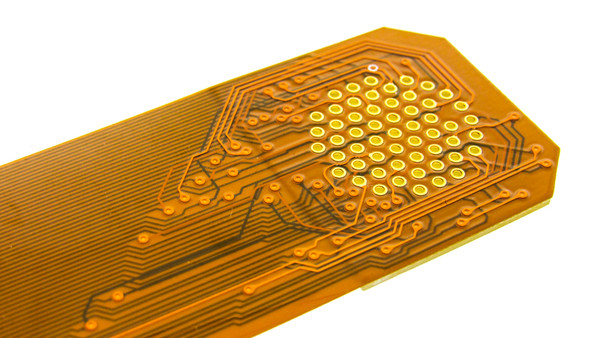

How to Ensure Your Flex Circuit Quick-Turn Will Not Get Delayed Webinar

In this webinar we will review key flex and rigid-flex technical items that we routinely encounter during the design review and production tooling engineering processes. These items often require technical questions to be asked and answered which in turn delays the production release and delivery of an order.

The objective is to address these items, if necessary, early on during the design phase and in advance of an order being placed so as not to incur any delays.

The most common items fall into 4 groups: Manufacturability, Materials, Functionality, and Reliability.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareWebinar Agenda:

-

Manufacturability

- Construction Requirements (per IPC 2223)

- Part Size/Shape

- Stiffener Requirements

- Min. Flex Length(s)

- Coverlay/Soldermask Configuration

- ZIF Contacts

- Pressure Sensitive Adhesive (PSA) Requirements

-

Materials

- Specific Material Brand Callouts

- Thickness Requirements

- Material Type(s)

-

Functionality

- Bend Requirement(s)

- Bend Once to Fit or Dynamic

- Controlled Impedance

-

Reliability

- Min. Bend Requirement(s)

- Gerber Layout (per IPC 2223)

- Construction (per IPC2223)