Successful Flex & Rigid-Flex Designs for Streamlining Production

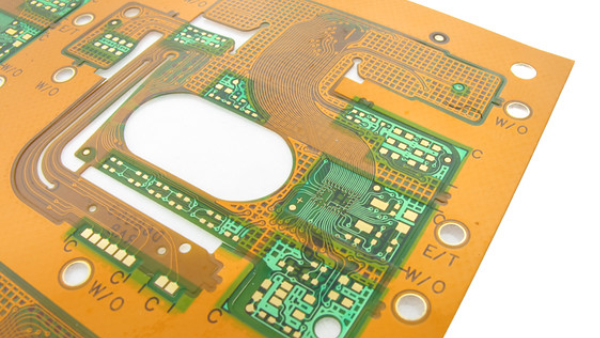

The flex and rigid-flex manufacturing process is inherently more complex with more process steps than those found in a rigid PCB of similar technology. When it comes to flex PCB designs, this is driven by the difference in materials combined with the many added items or features that can be incorporated into a design.

These include stiffeners (of varying materials / thickness / locations), pressure sensitive adhesives, shield layers, strain reliefs, etc. For rigid-flex designs this can become additionally complex as all the available flex items are combined with all the technical items found in rigid PCBs. These items potentially interact and can negatively impact the efficiency of the production process.

Streamlining is defined as making a process more efficient and effective. Having a design that streamlines the production process will have the benefits of improved delivery times, reduced part cost, improved manufacturing yield, and even potentially improved long-term part reliability.

In this webinar where we will review the many areas of flex and rigid-flex designs that can impact how streamlined a design is for production.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareWebinar Agenda:

- Proactive design for manufacturability reviews part construction and stack up requirements

- Complete, detailed, and accurate manufacturing data sets

- Material(s) selection

- Assembly array configurations

- Additional features (i.e.: stiffeners, PSAs, shield layers, strain reliefs)

- Impedance requirements

- Flex area via and plated through holes