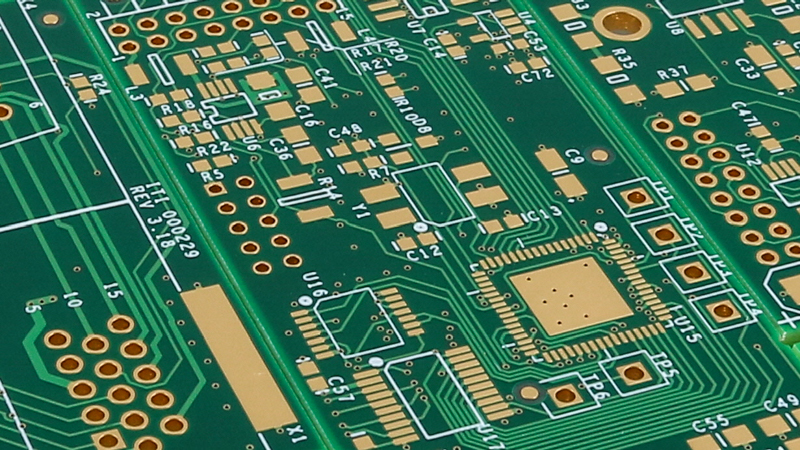

Low Layer Count PCBs - Why They Are Not All Created Equal

While many perceive high-tech PCBs as those with more layers, our aim is to outline the key areas that need to be understood when evaluating the capabilities of 2- and 4-layer PCB manufacturers. These versatile and cost-effective circuit boards can be as high-tech as their multi-layer counterparts, and our objective is to educate our audience as to what to look for to ensure that you get exactly what you are looking for.

Because of changes in technology, 2- and 4-layer PCBs continue to be at the forefront of high-tech electronics manufacturing, design strategies, manufacturing requirements, and the future of PCB technology, showcasing how these compact boards can rise to any challenge.

In this webinar, we cover design strategies, manufacturing requirements, and the future of PCB technology, showcasing how these compact boards can rise to any challenge. We also delve into the advantages and limitations of 2- and 4-layer PCBs, compare them to multi-layer boards, and discuss design tips to maximize their performance.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareCheck Out the Full Q&A

We have compiled all the questions submitted at the conclusion of this webinar into a readable format available on our blog.

Webinar Agenda:

- The basics of 2- and 4-layer PCBs – key features and benefits.

- Technology changes that have made 2- and 4-layer PCBs more attractive – then vs. now.

- What design considerations change the game in terms of cost and reliability – you will be surprised.

- Material selection – what is the impact on performance?

- Everyone can make these, so everyone’s quality is the same – right?

- Cost vs. functionality – why 2- and 4-layer boards work for many applications.