Using Rigid-Flex PCBs to Improve Design Reliability Webinar

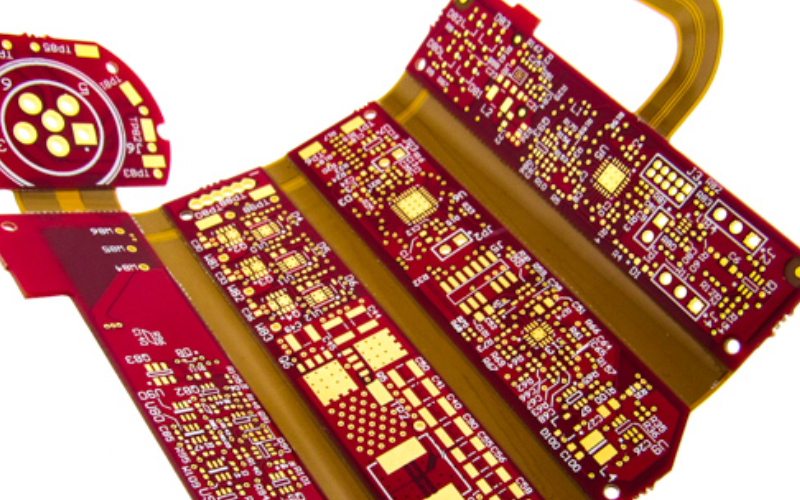

Reliability is a significant consideration in all designs, but more so in specific industries. The costs of either initial failures during assembly or more critically latent in the field failures can be excessive in both the expense and consequences. A benefit of rigid-flex technology is the ability to improve the reliability of a design. This applies to both the electrical functionality, and more importantly, the mechanical performance of the finished parts.

Mechanically, reliability is improved in two areas: the elimination of many points of interconnect between multiple rigid sections and a reduction in the total weight for improved shock and vibe performance. Electrically, rigid-flex designs allow for both improved signal integrity, for high-speed controlled impedance requirements, and effective shielding for EMI and RF sensitive designs.

In this webinar we review the multiple aspects of rigid-flex technology that will improve the reliability of your designs.

Watch the Recording Below

View the Presentation Slides

View the Slide Deck on SlideShareCheck Out the Full Q&A

We have compiled all the questions submitted at the conclusion of this webinar into a readable format available on our blog.

Webinar Agenda:

- Reduced points of failure through the elimination of points of interconnect

- Reduced weight for improved shock & vibe performance

- Improved minimum bend capabilities

- Improved high speed signal performance

- Effective EMI & RF shielding

- IPC 2223C guidelines for reliable constructions