Custom Battery Packs for Aerospace and Defense Applications

Designing custom battery packs for the aerospace and defense industries can be a complex process due to the demanding nature of these applications. There are several important factors that need to be considered when designing custom battery packs for aerospace and defense industries that are made of lithium-ion, lithium polymer, primary lithium, nickel-metal hydride (NiMH), nickel-cadmium (NiCd), and alkaline chemistries.

For a complete breakdown, take a look at our blog post, Challenges Designing and Manufacturing Lithium-Ion Battery Packs.

Factors to Consider

These factors include energy density, cycle life, safety, environmental impact, size, weight, temperature range, and application requirements.

Energy Density

Energy density is an important factor to consider when designing custom battery packs for aerospace and defense industries. High energy density batteries allow for a longer runtime while maintaining a small form factor. Lithium-ion batteries have a higher energy density compared to NiMH and NiCd batteries, making them ideal for aerospace and defense applications where weight and size are critical factors.

Cycle Life

Cycle life is another important factor to consider when designing custom battery packs for aerospace and defense industries. Cycle life refers to the number of charge and discharge cycles that a battery can undergo before its capacity begins to degrade. Lithium-ion and lithium polymer batteries have a higher cycle life compared to NiMH and NiCd batteries. Primary lithium batteries, on the other hand, have a much shorter cycle life, making them unsuitable for applications that require frequent charging and discharging.

Safety

Safety is a crucial factor to consider when designing custom battery packs for aerospace and defense industries. These industries require batteries that can operate reliably in harsh conditions and environments without posing a safety risk. Lithium-ion batteries have been known to experience thermal runaway, leading to explosions and fires. Designers should use safety mechanisms such as thermal fuses, protection circuits, and mechanical shut-off switches to mitigate the risks associated with lithium-ion batteries.

Environmental Impact

The environmental impact of batteries is a significant concern for the aerospace and defense industries. Battery chemistries such as NiCd and primary lithium contain toxic heavy metals that can harm the environment if not disposed of correctly. Designers should use battery chemistries that have a minimal environmental impact, such as lithium-ion and NiMH batteries.

Size and Weight

Size and weight are critical factors to consider when designing custom battery packs for aerospace and defense industries. These industries require batteries that are compact and lightweight without compromising performance. Lithium-ion and lithium polymer batteries have a higher energy density compared to NiMH and NiCd batteries, making them ideal for aerospace and defense applications where size and weight are critical factors.

Temperature Range

Temperature range is another important factor to consider when designing custom battery packs for aerospace and defense industries. These industries require batteries that can operate reliably in extreme temperature conditions without compromising performance. NiCd batteries have a wider temperature range compared to lithium-ion and lithium polymer batteries, making them suitable for applications that require operation in extreme temperature conditions.

Application Requirements

Lastly, the application requirements should be taken into consideration when designing custom battery packs for the aerospace and defense industries. Different applications have different requirements for voltage, capacity, and discharge rates. Designers should select battery chemistries and configurations that meet the specific requirements of the application. There are many key considerations when specifying a custom battery pack.

Experience with Aerospace and Defense Applications

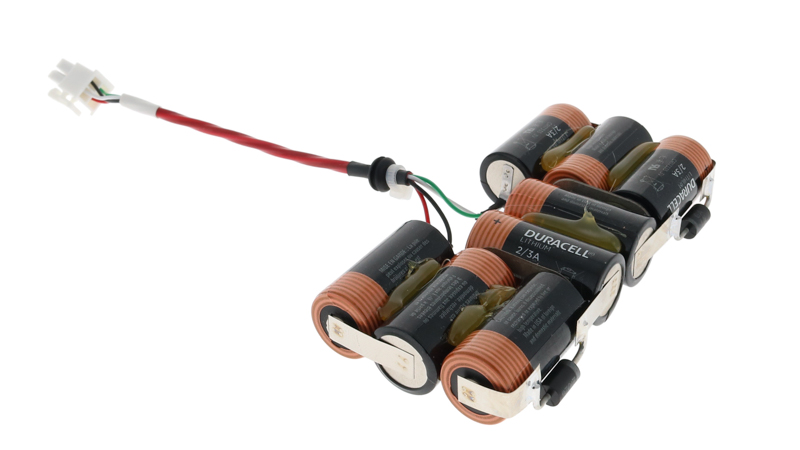

Epec Engineered Technologies has many years of experience in designing and manufacturing custom battery packs that include some of the most difficult hardware and software requirements in the industry. Our experience includes everything from simple alkaline packs to high-end lithium-ion packs with Battery Management Systems (BMS) and fuel gauging, metal or plastic enclosures, chargers, user interfaces, and many other features.

Designing custom battery packs for aerospace and defense industries is a complex process that requires careful consideration of various factors, including energy density, cycle life, safety, environmental impact, size, weight, temperature range, and application requirements. Designers should carefully select battery chemistries and configurations that meet the specific needs of the application and ensure that the battery pack is reliable, safe, and environmentally friendly.

Reliability In Critical Missions

Empower your aerospace and defense projects with Epec's expertise. Contact us for tailored battery solutions that meet your toughest requirements for mission critical applications.

Request a Quote Request Design Support Request More Information