Smart Battery Packs

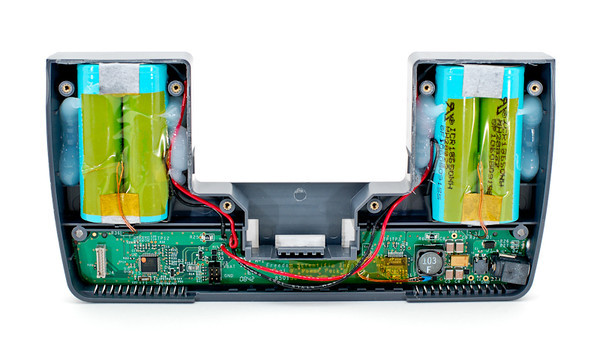

A smart battery pack provides the device with information so that it can manage its own charging, report errors, inform the device of low-charge conditions, predict remaining run-time, provide temperature, voltage, and current information, continuously self-correct to maintain prediction accuracy, and maintain its power status so that the device can conserve power intelligently. Smart battery packs can include many additional features and functionality, such as fuel gauge integration, communication protocol (I2C, SMBus, RS485, RS232 or CANBUS), cell balancing, and protection circuitry.

As all different types of equipment are becoming smaller and lighter, a custom lithium battery have the advantage of having high energy density, being light weight, wide operating temperature range, and the flexibility to use software and firmware to design the proper battery management systems (BMS) for every application.

One of the most critical parts of designing a custom battery pack is cell selection. Various chemistries are made in a wide variety of sizes, and custom battery packs offer the ability to dial in the performance of a specific cell chemistry to exactly match the performance that a device requires. A key thing to remember is that a smaller, lighter battery with the same energy density will usually cost more to produce and develop than a larger, heavier battery, which is why it is usually wise to work with an experienced custom battery pack designer before picking a specific cell technology.

The communication protocol architecture provides a means for keeping hardware costs low while also providing flexible functionality in a modular way. SMBus is a protocol that allows multiple nodes to respond to unique addresses. Details and specifications for SMBus can be found at www.smbus.org.

Added Value Electronics

As battery technologies continue to increase every day, today's batteries can now be viewed more as power systems/power supplies than normal batteries. Smart battery packs can offer embedded electronics, which improves the safety, reliability, cycle life, and functionality of the battery while giving the end-product system engineer more options to make the end product more reliable and user friendly. Smart battery packs can be designed using a BMS with features that include features that prevent charging in high temperatures or discharging in low temperatures, which can damage lithium batteries, encryption, backup power design, wide temperature demands (-20 to 50 degree C), shock-vibration durability, and battery status monitoring, which can be stored in memory or accessed remotely.

Smart Battery Pack Systems Can Now Include:

- Embedded battery chargers

- Unregulated input power

- Wireless power (charging)

- System output power

- Fuel gauging

- GPIO options

- Safety circuit (PCM)

- Intrinsically safe designs

- Authentication/encryption coding

- On board charging

- High C-rate discharging

- Remote monitoring

- Integrated power management

- Custom designed ruggedized molded and metal enclosures

- Safety certifications (IEC/UL 62133, UL2054, IATA UN38.3 and others globally)

- Labeling and packaging to meet all regulations

- U.S. and China manufacturing

With embedded battery chargers, batteries last longer by charging them to their ideal specifications and only within proper temperature limits. Properly designed and accurate fuel gauges, batteries can be discharged to almost empty with confidence; hence, batteries do not need to be oversized making them smaller, lighter, and more dependable. GPIO interface may provide access to information or functional control you had never thought possible.

Custom Battery Pack Production and Development Costs

Our experience has taught us that many times a technically ideal battery could be cost prohibitive when a customer is looking at developing a product within a budget. As engineers, we can design to almost any specification, which is why knowing your target costs very early on is critical to any successful launch of a battery pack project. What we have also found is that many times more expensive battery or a more robust charger can pay for itself several times over in the form of reduced replacement costs and/or better performance as improper charging is the most common cause of failure in rechargeable batteries.

Along with this, it is very important to share what your development budget is very early in the project so that we can communicate the costs of all of the items in your specifications so that together we can get a product that fits within your development and certification budget.

Optimize Your Device's Power Performance

Consult with our engineering team to help you achieve the ideal custom battery pack design with specifications to meet your product needs.

Request a Quote Request Design Support Request More Information