Battery Cell Comparison

The figures on this page have been acquired by a various number of sources under different conditions. Battery cell comparisons are tough and any actual comparison should use proven data for a particular model of battery.

Batteries perform differently due to the diverse processes used by various manufacturers. Even another model cell from the same manufacturer will perform differently depending on what they are optimized for.

You should also take into consideration the actual application in which the battery is being used. This can dramatically affect a battery's performance, so there are many factors to consider when choosing a battery cell for your product.

For more information, see our blog post on how to select the type of cell to use in your battery pack.

At a Glance: Battery Cell Comparison

- Battery cell performance varies significantly based on manufacturer processes and design optimizations.

- Even cells from the same manufacturer can behave differently depending on intended application.

- Actual usage conditions, such as operating environment and load requirements, greatly influence performance.

- Selecting the right cell requires considering energy density, cycle life, cost, and application-specific factors.

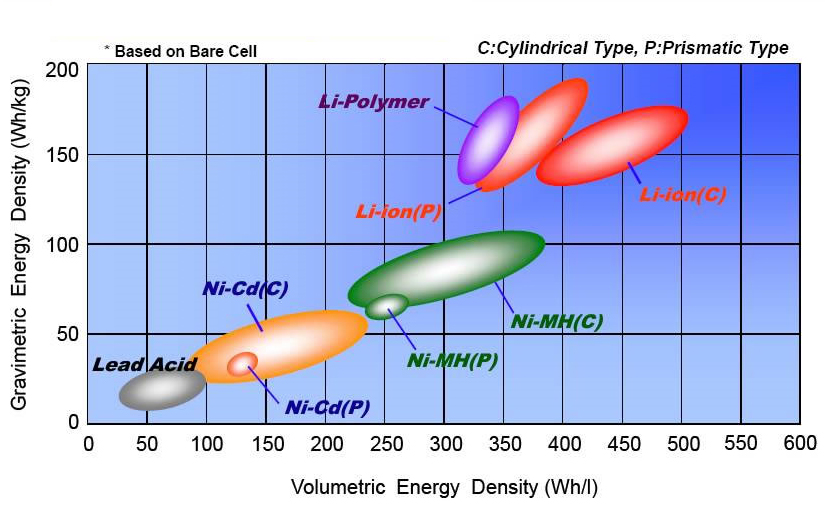

Comparison of Energy Density in Battery Cells

This battery comparison chart illustrates the volumetric and gravimetric energy densities based on bare battery cells.

Photo Credit: NASA - National Aeronautics and Space Administration

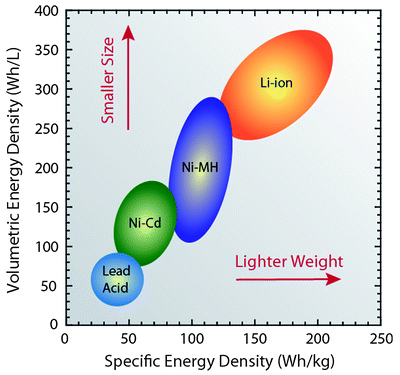

Photo Credit: NASA - National Aeronautics and Space Administration

Energy Density Comparison of Size & Weight

The below battery comparison chart illustrates the volumetric and specific energy densities showing smaller sizes and lighter weight cells.

Specifications by Battery Chemistry

| Specifications | Lead Acid | NiCd | NiMH | Li-ion | ||

|---|---|---|---|---|---|---|

| Cobalt | Manganese | Phosphate | ||||

| Specific Energy Density (Wh/kg) | 30-50 | 45-80 | 60-120 | 150-190 | 100-135 | 90-120 |

| Internal Resistance (mΩ) | <100 12V pack |

100-200 6V pack |

200-300 6V pack |

150-300 7.2V |

25-75 per cell |

25-50 per cell |

| Life Cycle (80% discharge) | 200-300 | 1000 | 300-500 | 500-1,000 | 500-1,000 | 1,000-2,000 |

| Fast-Charge Time | 8-16h | 1h typical | 2-4h | 2-4h | 1h or less | 1h or less |

| Overcharge Tolerance | High | Moderate | Low | Low. Cannot tolerate trickle charge | ||

| Self-Discharge/month (room temp) | 5% | 20% | 30% | <10% | ||

| Cell Voltage (nominal) | 2V | 1.2V | 1.2V | 3.6V | 3.8V | 3.3V |

| Charge Cutoff Voltage (V/cell) | 2.40 Float 2.25 |

Full charge detection by voltage signature |

4.20 | 3.60 | ||

| Discharge Cutoff Voltage (V/cell, 1C) | 1.75 | 1.00 | 2.50-3.00 | 2.80 | ||

| Peak Load Current Best Result |

5C 0.2C |

20C 1C |

5C 0.5C |

>3C <1C |

>30C <10C |

>30C <10C |

| Charge Temperature | -20 to 50°C -4 to 122°F |

0 to 45°C 32 to 113°F |

0 to 45°C 32 to 113°F |

|||

| Discharge Temperature | -20 to 50°C -4 to 122°F |

-20 to 65°C -4 to 149°F |

-20 to 60°C -4 to 140°F |

|||

| Maintenance Requirement | 3-6 Months (topping charge) |

30-60 days (discharge) |

60-90 days (discharge) |

Not required | ||

| Safety Requirements | Thermally stable | Thermally stable, fuse protection common | Protection circuit mandatory | |||

| In Use Since | Late 1800s | 1950 | 1990 | 1991 | 1996 | 1999 |

| Toxicity | Very High | Very High | Low | Low | ||

Different battery chemistries offer unique performance characteristics, making it important to compare factors such as energy density, cycle life, and cost. Selection depends on application requirements, including size, weight, and environmental conditions. Understanding these trade-offs ensures optimal performance and reliability for the intended use.

Frequently Asked Questions

Quick Links

- Which specifications matter most when comparing battery cells?

- What should be considered beyond basic specifications?

- Why is energy density important?

- How does cycle life affect battery selection?

- Are all chemistries equally suited for extreme environments?

Which specifications matter most when comparing battery cells?

The most critical specifications include energy density, cycle life, cost, and environmental performance because these factors directly influence how well a battery meets application requirements. Energy density determines how much power can be stored in a given size or weight, which is vital for portable or space-limited designs. Cycle life impacts long-term reliability and cost-effectiveness, as batteries with higher cycle counts last longer before needing replacement. Cost considerations affect overall project budgets, while environmental performance ensures the battery can operate safely under expected conditions.

What should be considered beyond basic specifications?

Beyond the core specifications, factors such as operating temperature range, safety characteristics, and long-term reliability are essential for selecting the right battery. Temperature tolerance is critical for applications exposed to extreme heat or cold, as performance can degrade outside safe limits. Safety features, including resistance to thermal runaway or short circuits, help prevent hazardous failures. Reliability over time ensures consistent performance, reducing maintenance and replacement costs in demanding environments.

Why is energy density important?

Energy density is a key metric because it defines how much energy a battery can store relative to its size and weight. Higher energy density allows for smaller, lighter battery packs without sacrificing power, which is crucial for portable electronics, medical devices, and electric vehicles. This advantage can lead to improved design flexibility and better user experience in applications where space and weight are limited. Choosing a chemistry with optimal energy density can significantly enhance overall system efficiency.

How does cycle life affect battery selection?

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its capacity drops below a usable level. A longer cycle life means the battery will last through more operational cycles, reducing replacement frequency and lowering total cost of ownership. Applications with frequent charging, such as electric vehicles or industrial equipment, benefit greatly from chemistries with high cycle life. This specification is a major factor in determining long-term reliability and economic viability.

Are all chemistries equally suited for extreme environments?

No, different chemistries respond differently to temperature extremes and environmental stress. Some batteries maintain performance in high or low temperatures, while others experience rapid degradation or safety risks under the same conditions. For example, certain lithium chemistries may perform well in cold climates, whereas others are better suited for high-heat environments. Understanding these limitations ensures the chosen battery will operate safely and efficiently in its intended setting.

Not Sure What Your Best Cell Option Is?

Ready to make a choice for your next battery cell but not sure what is the best option? Dive into our comprehensive guide to selecting the right type of cell for your project. Contact us today to talk with a member of our engineering team.

Request a Quote Request Design Support Request More Information