Protection Circuit Modules

Safety protection against overheating is essential in every lithium battery pack. While UL regulations define specific safety requirements, compliant hardware alone is not enough. Proven experience in electronics design and physical protection methods plays a critical role in ensuring the safe operation of an end product, especially in real-world and high-reliability environments.

At a Glance: Protection Circuit Modules

- Protection Circuit Modules (PCMs) are a critical safety component of custom lithium battery packs.

- PCMs provide electronic safeguards against overheating and other failure conditions as part of the battery management system (BMS).

- Properly designed primary and secondary protection circuits are essential when off-the-shelf solutions do not meet application requirements.

Primary Safety Circuits

Primary safety circuits handle the core protection functions within a battery pack. These include overvoltage, undervoltage, and overcurrent protection, along with overtemperature and undertemperature monitoring in some designs. Together, these functions form the first line of defense against conditions that could damage cells or compromise system safety.

Protection Circuits and Secondary Safeguards

In many world-class battery pack designs, a secondary safety circuit is added alongside the primary circuit. This secondary protection is intended to protect the lithium cell while charging if the primary safety circuit fails. Incorporating both primary and secondary mechanisms significantly improves overall system reliability, particularly in critical or portable applications.

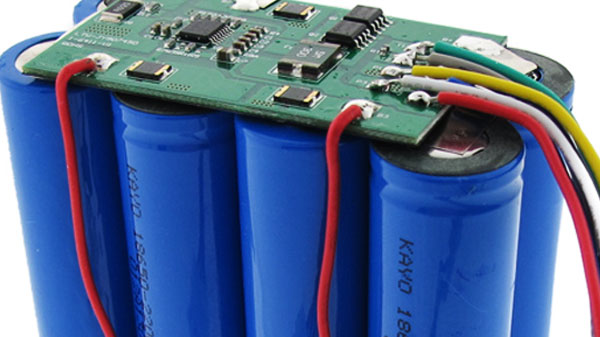

These protection circuits are housed in what is commonly known as the Protection Circuit Module (PCM). Although off-the-shelf PCMs are widely available, each battery application requires specific operating parameters to be maintained. For this reason, standard modules are generally suitable only for laboratory prototypes and are not recommended for production designs.

Protection Circuit Modules Within the BMS

The Protection Circuit Module (PCM) functions as part of the broader Battery Management System (BMS). The BMS manages the electronics of a rechargeable battery pack by monitoring its state, reporting operating data, balancing cells, protecting the battery from unsafe conditions, and controlling its operating environment. Within this system, the PCM plays a central role in enforcing safety limits.

For demanding applications, battery protection circuits are typically built around integrated circuits (ICs) and MOSFETs. These components switch lithium cells in and out of the circuit as needed. Overcurrent protection is usually triggered when the IC detects that the battery has reached its upper current limit and then interrupts the circuit to prevent damage.

Fail-Safe Environments and Design Experience

Many protection features can be designed to reset automatically once a fault condition is cleared. In fail-safe environments, however, these protections may be intentionally designed as non-resettable. This approach ensures that a potentially unsafe battery pack cannot return to service without inspection or replacement.

The two primary manufacturers of protection ICs referenced in these designs are Texas Instruments (TI) and Sieko. Both require system-level programming based on the specific functionality of the battery pack. Working with an experienced design partner is critical, as this experience includes access to established software and firmware libraries that can be adapted efficiently across applications.

Importance of Protection Circuit Modules

As major battery cell manufacturers shift their focus from smaller applications toward the electric vehicle market, many newer and smaller suppliers are now producing cells used in critical applications. This industry shift increases the importance of robust protection circuit design.

PCMs that incorporate both primary and secondary safety mechanisms are essential for companies developing portable devices that must be safe, reliable, and durable. Without these layered protections, the risk of cell damage or unsafe operation increases significantly.

Protect Circuits for Custom Battery Packs

Epec engineers’ custom battery packs with advanced protection circuits tailored to the requirements of each application. By prioritizing safety, reliability, and fail-safe design, these solutions address the risks associated with lithium battery operation in demanding environments.

Consulting with an experienced engineering team ensures that protection circuits are correctly specified, programmed, and integrated into the overall battery management system for long-term, dependable performance.

Frequently Asked Questions

Quick Links

- What is a Protection Circuit Module (PCM)?

- What safety functions do primary protection circuits provide?

- Why are secondary safety circuits used in some battery packs?

- Are off-the-shelf PCMs suitable for production battery packs?

- How does the PCM relate to the Battery Management System (BMS)?

- Can protection circuits be non-resettable?

What is a Protection Circuit Module (PCM)?

A PCM is an assembly that contains battery protection circuits. It manages safety functions such as voltage, current, and temperature limits within a lithium battery pack.

What safety functions do primary protection circuits provide?

Primary safety circuits typically handle overvoltage, undervoltage, overcurrent, and in some cases overtemperature and undertemperature protection.

Why are secondary safety circuits used in some battery packs?

Secondary safety circuits provide additional protection if the primary circuit fails, particularly during charging, helping prevent damage to the lithium cell.

Are off-the-shelf PCMs suitable for production battery packs?

Off-the-shelf PCMs are generally recommended only for lab prototypes. Production applications require custom parameters that standard modules cannot reliably maintain.

How does the PCM relate to the Battery Management System (BMS)?

The PCM is part of the BMS, which monitors battery state, reports data, balances cells, protects the battery, and controls its operating environment.

Can protection circuits be non-resettable?

Yes. In fail-safe environments, protection circuits can be designed so that they do not reset after a fault, ensuring unsafe packs are not reused without evaluation.

Protect Circuits for Custom Battery Packs

Prioritize safety and reliability with our expertly engineered custom battery packs featuring advanced protection circuits. Consult our engineering team for a customized, fail-safe solution.

Request a Quote Request Design Support Request More Information