Oceanographic Battery Pack Technologies

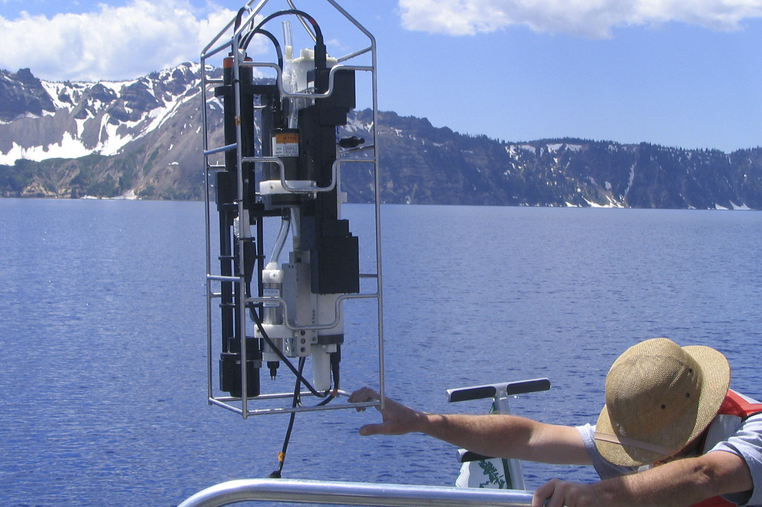

Custom designed battery packs for underwater oceanographic equipment need to be extremely reliable and built to last under extreme conditions. These types engineered battery packs are used by universities, research institutes, and oceanographic survey operations to power equipment used underwater, for downhole oil field applications, or for pipeline inspection operations.

Each application will have unique requirements, but the largest challenges to overcome in the design are the long-term deployments of these packs and making sure that we can extend the duration of each deployment.

The chemistries that we offer include lithium thionyl chloride, nickel metal hydride, and alkaline cells which are selected based upon the specifications of each application.

Oceanographic Equipment Using a Custom Battery Pack

Oceanographic Equipment Using a Custom Battery Pack Epec engineers and manufactures battery packs used in:

- Subsea Monitoring

- Water Use and Contaminant Monitoring

- Subsea Navigation

- Underwater Surveillance Systems

- Monitoring Buoys

- Remote Pipeline Inspection

- Hydrographic Survey Equipment

- Acoustic Release

- Mini Beacons and Current Meters

Our experienced in house mechanical and electrical engineering teams will assist customers with following:

- Design and creation of product specification.

- Engineering all the necessary Battery Management System (BMS) components if necessary.

- Utilizing the most leading-edge electronics to ensure safety and efficient operation in every design.

- Develop the most cost-effective packaging of the cells and electronics to deliver the power in the footprint required by the customer.

- Create all the in-house test equipment and procedures to ensure 100% reliability (electrical, environmental, physical, etc.).

- Develop all the needed tooling to efficiently manufacture and test the product.

- In-house manufacturing capability for all potting under vacuum, mold making, and enclosure encapsulation.

- Manage any initial and ongoing certifications that may be required (UL, CE, UN DOT, IATA, compliant for use in explosive atmospheres. (e.g. ATEX, IECEx)).

Many times, these applications can require packs that can be up to 10 ft long, containing several hundred cells that are hand-assembled on custom-made tooling to meet precise dimensional requirements. The often also include safety devices, high-specification thermal insulation, incorporated heating devices, and many other unique requirements for these demanding applications.

Our lean manufacturing set up at our production facility is specifically developed for high mix, medium to low volume applications which allows us to quickly switch from one project to the next while quickly and accurately delivering for our customers.

Effective Battery Systems

While we work with the most advanced battery cell manufacturers in the world, effective battery systems that deliver high performance and operates safely in use and on-charge requires more than just the right cells. These complex applications require more than just creating a bill of materials and low-level manufacturing.

To be effective a company must understand implementing redundancies in a system even in low cost alkaline packs as one bad spot weld can make a device useless to its use for a very long period of time. Or truly comparing the tradeoffs between battery pack capacity and the duration of the charge needed and even the capacity versus the temperature environment that it will be operating in so that battery back will supply more of its capacity to the instrument as opposed to internal dissipation.

Even when selecting the proper components such as using low power loss, high efficiency protection diodes to utilizing our 20 plus years of experience with flexible PCBs to minimize loss in connections inside the pack, assist in creating the most efficient design.

Epec also provides additional services, including refurbishment service for the products that we produce with fast and efficient turn around.

Enhance Your Oceanographic Equipment's Reliability

Contact us for custom battery packs designed to endure extreme conditions and extend deployments.

Request a Quote Request Design Support Request More Information