Battery Pack Manufacturing Process

Below are images from the battery pack manufacturing process. All our custom battery packs go through intensive testing and quality control during each step of manufacturing.

-

State of the Art Battery Manufacturing in New Bedford, MA

Temperature and humidity control, ESD protection, and specialized fire control equipment are just a few of the few of the requirements of a company if they want to work with companies like Sanyo and Panasonic. -

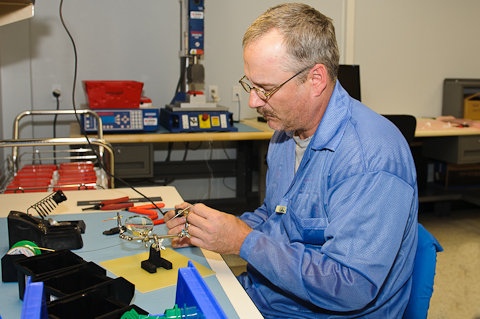

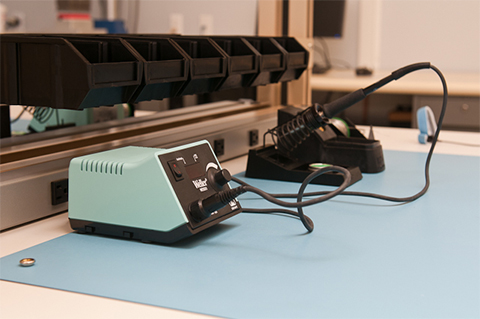

IPC Certified Soldering

All of our soldering technicians are IPC trained and certified so that we can assure the highest level of quality on our product. -

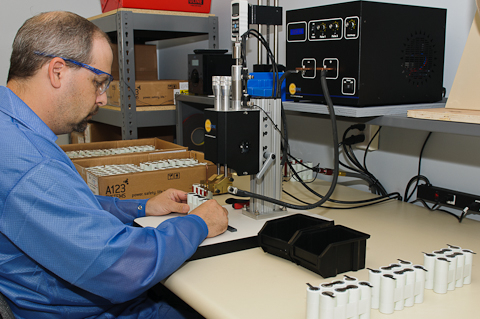

Spot Welding Process

The most attractive feature of newest spot welding equipment is that the energy delivered to the spot can be controlled to produce reliable welds. -

Heat Shrink Oven

The Heat Shrink Oven shrinks tubing in a fraction of the time required by a heat gun as it reaches the optimum operating temperature to quickly and uniformly shrink tubing. -

Soldering Stations

Our dedicated and ESD protected soldering stations allow us to manage multiple assemblies during our 24/7 operation. -

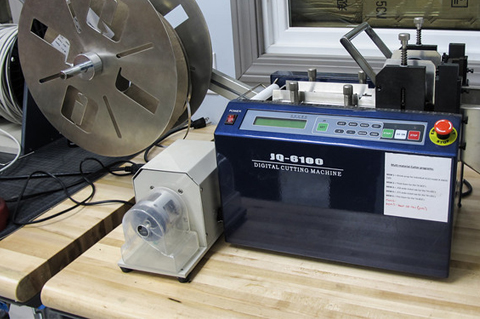

Wire Cutting and Stripping

To optimize production rate, repeatability and accuracy of the wire length, Epec has continued to invest in equipment to ensure quality. -

Ultrasonic Welding Equipment

Each custom battery pack that requires a plastic enclosure can be sealed by adhesives, mechanical screws or the latest in ultrasonic technology. -

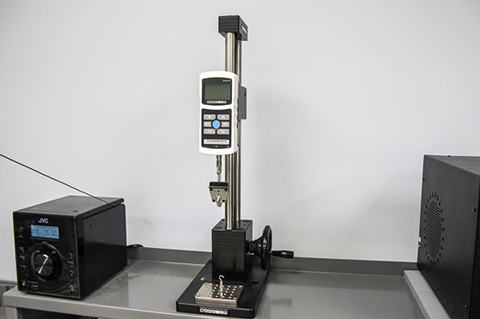

Pull Test Equipment

Used to measure the strengths of the tab welds on the cells to ensure that the connections last while in use. -

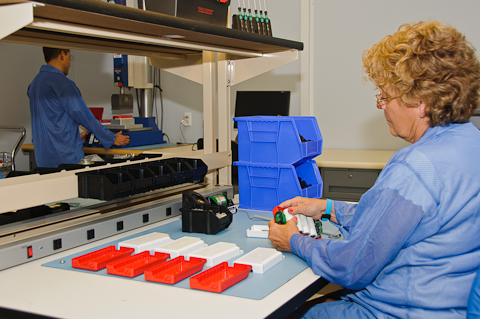

Final Assembly

At this step all of the pieces are put together in the final assembly. These can include printed circuit boards, thermistors, membrane switches and many other products depending upon the features of the battery pack. -

Custom Testing Equipment and Procedures

Battery testing is done on battery packs at both the prototype and production levels. Our in-house capabilities allow us the ability for programming and testing that may be required at the customer level.

Quality At Every Stage Of Manufacturing

Ensure your power solutions meet the highest standards. Experience quality at every stage of our battery pack manufacturing process.

Request a Quote Request Design Support Request More InformationRequest a FREE Quote!

We are here to help you will all your custom battery pack needs.

-

Battery Pack Solutions

- Overview

- Smart Battery Packs

- Custom Battery Packs

- Custom Lithium Battery Packs

- Custom NiMH Battery Packs

- Custom Alkaline Battery Packs

- Standard vs Custom Battery Packs

- Wireless Charging Technologies

- Embedded Battery Chargers

- System Output Power

- Fuel Gauges for Battery Packs

- Battery Pack GPIO Options

- Protection Circuit Modules

- Battery Management Systems

- Battery Potting & Encapsulation

-

Battery Cell Technologies

-

Battery Pack Capabilities

-

Industries & Market Focus

-

Design & Development

-

Additional Resources

Ebook - Battery Pack Designs with Lithium-Ion Chemistries