Battery Pack GPIO Options

General Purpose Input/Outputs (GPIO) can be added to almost any custom battery pack and can be used to control any battery subsystem or control end-product functions using a simple two-wire interface, I2C.

When to Use GPIO in Your Application

The addition of GPIO can be useful when the end system needs additional logic support that was not originally built into the product, or if the logic supports changes based on different end product SKU levels. Visit this article, Integrating GPIO Options in Your Custom Battery Pack to find out more about using GPIO in your application.

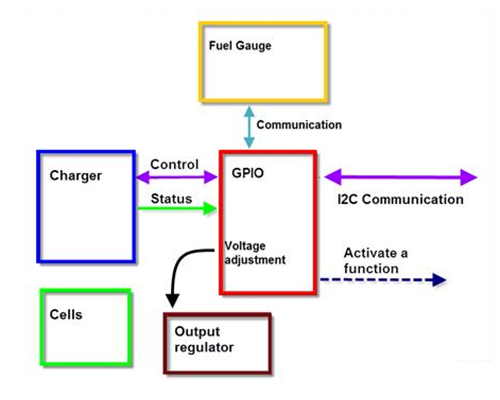

Diagram Depicting How Battery Pack GPIO Options Work

Diagram Depicting How Battery Pack GPIO Options Work

It can serve as the "glue logic" that links various subsystems together as shown in the diagram above. It can be particularly useful when a single battery must support different products with widely varying parameters.

An example of this is when different products require different regulated voltages. The GPIO can be used to adjust the battery's output regulator depending on the software commands from each system, allowing one battery pack to support many different products.

Examples GPIO Options

- Adjust battery charger current.

- Turn LED indicators on and off.

- Automated production BIT.

- Read internal hardware status indicators.

- Voltage monitoring.

- Activate or switchover multiple battery banks.

- Adjust on-board voltage regulators as needed by the fuel gauge or end product.

- Self-destruct to protect IP (for military applications).

Cost Factors of Integrating GPIO Options in Your Battery Pack

Integrating GPIO options to you application does add costs to the final battery pack assembly. When it comes to GPIO, the costs vary widely do to the number of possibilities and features that can be added to tailor the battery pack to very specific needs for your application.

Looking for a Battery Packs with GPIO Options?

Maximize versatility and control with our custom battery packs featuring GPIO options. Consult our experts to tailor your solution to your application.

Request a Quote Request Design Support Request More Information