Wireless Power Charging Technologies

Using the Qi inductive power standard, Epec can embed wireless charging electronics into a custom battery pack that works with off-the-shelf wireless charging pads that already exist. In addition to supporting standard charging pads, Epec also offers inhouse engineering resources to develop a custom charging pad tailored to the specific needs of an end product. This flexibility allows wireless charging to be adapted to a wide range of device form factors and use environments while remaining integrated within the battery pack.

At a Glance: Wireless Charging

- Integrates Qi (inductive power standard) electronics directly into a custom battery pack for use with existing off-the-shelf charging pads or a custom-designed pad.

- Uses planar coils and continuous pad-to-battery communication to verify battery presence and alignment before and during power transfer.

- Commonly selected when electrical contacts are undesirable or inaccessible, such as embedded batteries or sealed products.

How Does Wireless Charging Work?

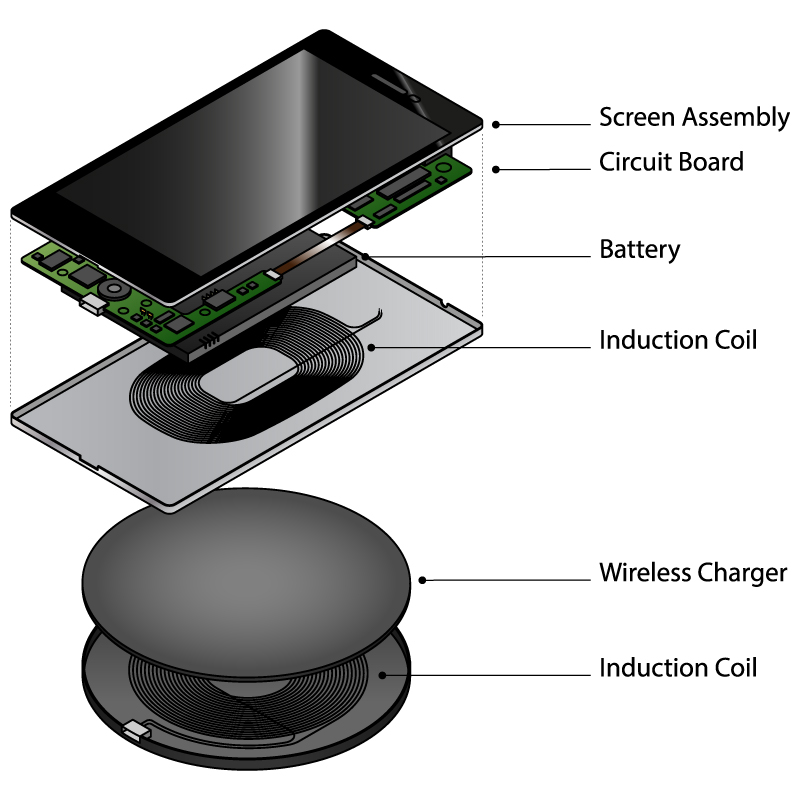

A wireless charging system consists of two primary components: the charging pad and the battery pack. Each includes planar coils that transfer energy from the pad to the battery. Electrical energy is modulated so the charging pad and battery can communicate with each other during operation. This communication enables the charging pad to confirm that a valid battery is present before transmitting full power.

Diagram Depicting How Wireless Charging Works

Diagram Depicting How Wireless Charging Works

The communication link remains active throughout the entire charging cycle to ensure the battery remains in place. By verifying presence and alignment continuously, the system reduces EMI emissions from the charging pad when it is not actively charging a battery.

Advantages of Wireless Charging

Wireless charging is particularly useful when traditional electrical contacts are not acceptable. This often applies when the battery is fully embedded in the product or the product itself cannot be easily reached. Common applications include medical devices and food-related products, where minimizing electrical shock risk, reducing bacteria exposure, and eliminating exposed contacts are important design requirements.

Wireless charging can also reduce the number of cables and power adapters that must be custom-manufactured for a device or application. Depending on the battery pack size and design, wireless charging can deliver sufficient power to support practical charge rates.

Wireless Charging Power and Distance Capabilities

| Parameter | Value | Units |

|---|---|---|

| Wireless charging power delivery | 5 or 10 | W |

| Typical coil-to-coil distance | 5 | mm |

| Extended possible coil-to-coil distance | ≥35 | mm |

Wireless charging systems can be sized to deliver either 5 W or 10 W of energy to the battery. In most applications, the distance between the charging pad coil and the battery coil is typically about 5 mm, though it is possible to extend that distance to at least 35 mm in certain designs.

Cost Factors of Wireless Power Charging Technologies

The cost of wireless power charging technologies has decreased as adoption has increased in the portable device market. Even with these reductions, wireless charging should still be selected only when there is a clear need for it within the application. Hardwired connector-based charging solutions remain more cost-competitive in many cases and are capable of delivering faster charge times and higher energy transfer.

Evaluating cost, charge speed, and application constraints is an important step when deciding whether wireless charging is the appropriate solution for a given battery pack design.

Frequently Asked Questions

Quick Links

- What wireless charging standard does Epec support?

- Can the battery pack work with existing wireless charging pads?

- Is it possible to design a custom charging pad?

- How does the charging pad know when to send power?

- Why does wireless charging reduce EMI when not in use?

- When is wireless charging preferred over hardwired charging?

- Is wireless charging always the most cost-effective option?

What wireless charging standard does Epec support?

Epec supports the Qi inductive power standard and can embed compatible charging electronics into a custom battery pack.

Can the battery pack work with existing wireless charging pads?

Yes. Wireless charging electronics can be integrated so the battery pack works with off-the-shelf wireless charging pads that already exist.

Is it possible to design a custom charging pad?

Epec has inhouse engineering resources to help develop a custom charging pad specific to an end product when needed.

How does the charging pad know when to send power?

The charging pad and battery communicate with each other, allowing the pad to verify that a valid battery is in place before transmitting full power.

Why does wireless charging reduce EMI when not in use?

Continuous communication during charging confirms whether the battery is present, reducing EMI emissions from the charging pad when it is not actively charging.

When is wireless charging preferred over hardwired charging?

Wireless charging is preferred when electrical contacts are not acceptable, the battery is embedded, or the product cannot be easily accessed.

Is wireless charging always the most cost-effective option?

No. Hardwired charging solutions are generally more cost-competitive and can deliver faster charge times and more energy, so wireless charging should be used only when the application requires it.

Looking For A Wireless Charging Solutions?

Epec offers Qi-compatible wireless charging solutions that can be integrated directly into custom battery packs. These solutions are well-suited for applications such as medical devices and other products where wired connections are not practical or acceptable, and where system-level integration and engineering support are required.

Get a free consultation today and meet your portable device power requirements.

Request a Quote Request Design Support Request More Information