System Output Power

All lithium-ion (Li-ion) batteries require a battery management system (BMS). This is due to the fact that all Li-ion batteries will fail if overcharged, completely discharged, or operated outside their safe temperature window. Each Li-ion cell type has its own safe operating area, which makes it necessary to program the BMS accordingly.

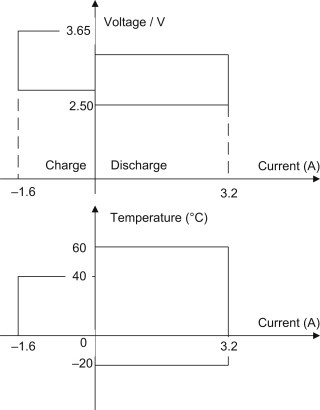

The figure below shows the safe operating area typical for a C/lithium iron phosphate cell.

In low-cost systems, there might be some differences in the requirements or functions for the BMS, especially for a low number of cells in series (e.g. 12V systems with four cells in series), some battery system manufacturers propose a simple external undervoltage shutoff circuit and a charger with controlled end-of-charge voltage.

For larger and more complex systems, the BMS guarantees the protection of highly expensive components and adds to the system functionality.

Difference Between Battery, Module, and Cell

To begin with, it is important to understand the difference between the terms "battery," "module," and "cell."

Basically, a battery is the completely assembled pack with electrical, mechanical and communication signal interfaces.

The battery pack may consist of several modules that are wired in series and/or (less often) parallel. A module can be described as a part of the battery and is normally contained in the battery housing, although with very large batteries the modules can also be connected separately through cables.

In each module, single cells are connected in series or parallel. If the modules are connected in parallel, then it is possible to obtain higher currents and a series connection leads to a higher voltage. In a module, every cell has to be monitored to guarantee a proper function in the desired operating range (voltage, current, and temperature). The control of these modules is realized with a module control unit (MCU).

In a battery pack, several of these MCUs are connected directly or through a communication bus with a supervisory circuit or battery control unit (BCU) that, based on the input of the MCU, calculates historical values and incorporates any measures needed to protect the battery and maintain the performance of the pack. Some of these additional functions can be described as follows:

- Protect the cells from being operated outside the threshold condition.

- Balance the charge in the individual cells to maintain symmetry between the cells or to enhance overall available capacity.

- Disconnect the battery during emergency conditions in a safe way.

- Communicate relevant data for the driver displays and alarm functions.

Optional System Output Power Design

Custom circuitry can be added to your battery pack BMS to make it behave more like a power supply or UPS system rather than a typical battery. These types of battery pack power systems are useful in applications that:

- Need instant UPS power in the event of input power failure.

- Need more power than can be provide by the input power source.

- Are Sensitive to power fluctuations.

How Does It Work?

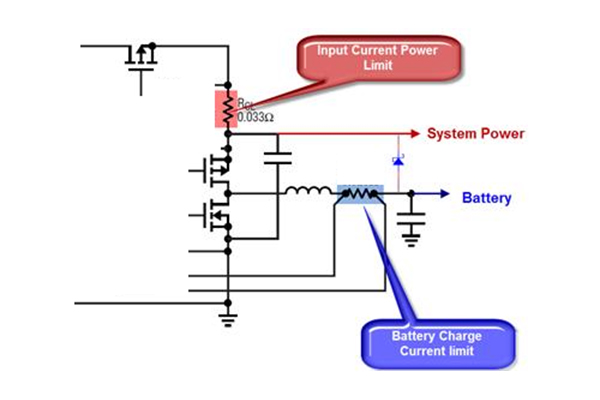

A typical typology of a battery that offers system power that is derived from either the input power source or the battery is defined in the diagram below. It shows a typical arrangement capable of providing power from an external source to the system power input while charging the battery if needed.

In the event input power fails, system power receives energy from the battery via the ideal diode shown in blue.

Diagram Depicting Battery System Output Power

Diagram Depicting Battery System Output Power

If a high-power demand accrues that is greater than the capability of the input power supply, the input current limit resistor shown in red above can be sized to allow supplemental power to be supplied by the battery. This is convenient when occasional surges are expected but do are not sufficient enough or long enough to justify a larger input power source. Output regulators can also be added to provide a regulated output power source. Adding this type of capability varies with every system due to the number of power variables and operating environments.

Custom BMS Solutions

Ensure safe and efficient li-ion battery operation with Epec’s custom BMS solutions. Contact us for more information or to get a quote.

Request a Quote Request Design Support Request More Information