Battery Pack Development Timeline

Concept Through Production

Here you will find our battery pack development timeline process. This will cover the scope of the project needed and the time between developing prototypes and finally end product production. Here is what to expect for battery development timelines.

For more information, see our blog post on battery management and logistics monitoring.

Click on a link below to see the timeline for these types of battery projects.

- Ni-MH, NiCd, and Alkaline Battery Packs

- Standard Lithium Battery Packs

- Non-Standard Lithium Battery Packs

- DOT /UN38.3 Certification

- UL2054 Certification

- IEC62133–2 Certification

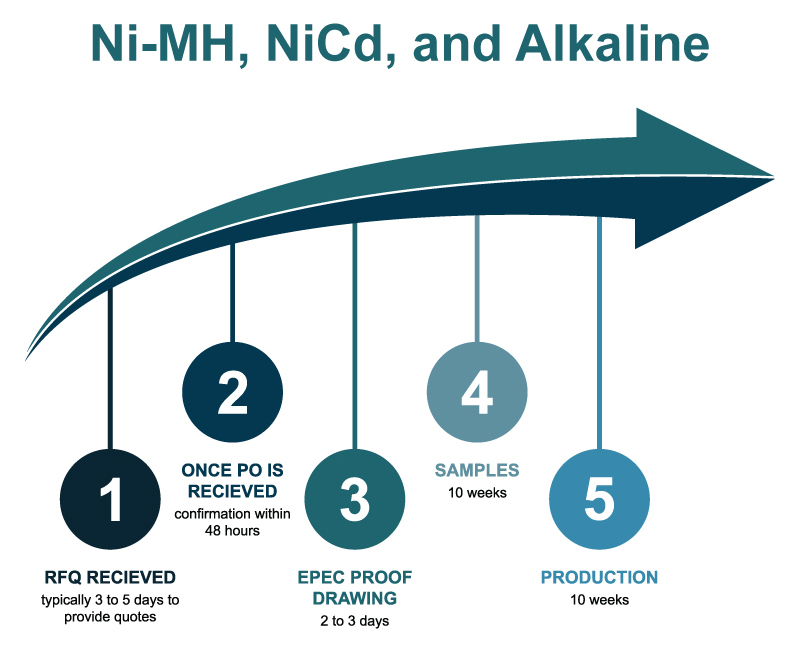

Ni-MH, NiCd, and Alkaline Battery Packs

- RFQ received, typically 3 to 5 days to provide a quote, depending on the complexity of the design.

- Once the purchase order (PO) is received, it will be entered and confirmed to the customer within 48 hours.

- All battery projects need to begin with samples for the customer to receive, test, and approve. The sample quantity is determined by the customer during the quote process.

- The sample process begins with an Epec proof drawing created and submitted to the customer for approval before assembling sample/s batteries. This will take anywhere from 2 to 3 days, depending on the complexity of the battery.

- The proof is then submitted to the customer for their design review for approval to proceed with or changes they may want. Typically, the customer will provide approval or feedback within 3 to 5 days, and if edits or changes are needed, the proof is revised, resubmitted for approval again.

- With the proof approved, we will proceed with the determined number of samples, and the lead time is typically 10 weeks.

- The customer receives the completed samples and will need to perform their review and /or testing to provide formal approval to proceed with the production quantity. This process is very determined with some customers doing a quick bench-level test, to some customers having to install it in their device or equipment, to then run through extensive testing before they can determine the battery pack is acceptable. This customer review for the approval step can take anywhere from 1 day to several months, depending on the testing needed.

- If the battery pack is approved, we proceed with production, lead time to complete is typically 10 weeks unless there are long lead items for the battery pack.

- If the samples need to be changed /modified, we will need to go through the proof process again with the updates prior to producing the next round of samples. (following the above timelines)

NiMH, NiCD, Alkaline Battery Pack Development Timeline Explained

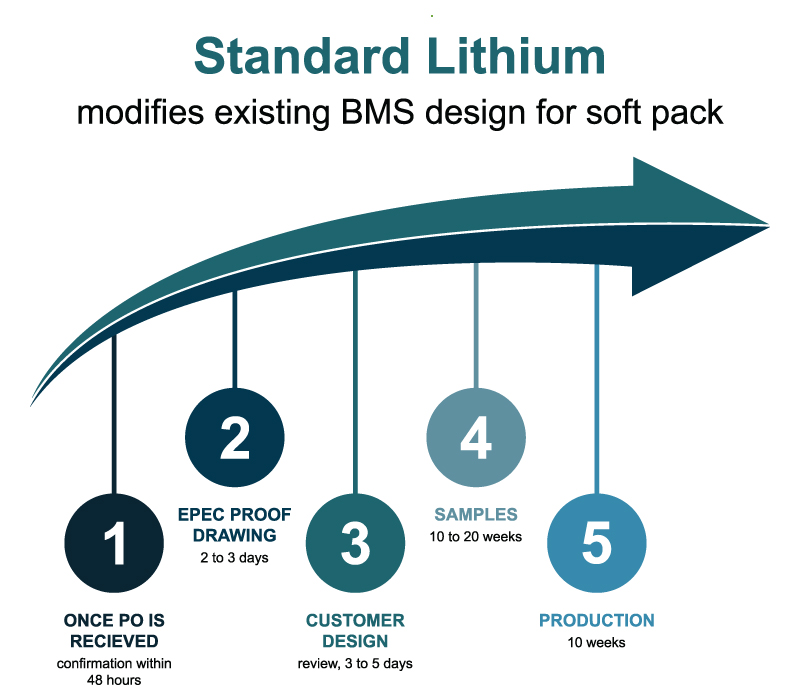

Standard Lithium Battery Packs

Standard lithium, which modifies the existing battery management system (BMS) design for the pack and will be a soft pack.

- RFQ received, typically 3 to 5 days to provide a quote, depending on the complexity of the design.

- Once the PO is received, it will be entered and confirmed to the customer within 48 hours.

- All battery projects need to begin with samples for the customer to receive, test, and approve. The sample quantity is determined by the customer during the quote process.

- The sample process begins with an Epec proof drawing created and submitted to the customer for approval before assembling sample/s batteries. This will take anywhere from 2 to 3 days, depending on the complexity of the battery.

- The proof is then submitted to the customer for their design review for approval to proceed with or changes they may want. Typically, the customer will provide approval or feedback within 3 to 5 days, and if edits or changes are needed, the proof is revised, resubmitted for approval again.

- With the proof approved, we will proceed with the determined number of samples, and the lead time is typically 10 weeks.

- The customer receives the completed samples and will need to perform their review and /or testing to provide formal approval to proceed with the production quantity. This process is very determined with some customers doing a quick bench-level test, to some customers having to install it in their device or equipment, to then run through extensive testing before they can determine the battery pack is acceptable. This customer review for the approval step can take anywhere from 1 day to several months, depending on the testing needed.

- If the battery pack is approved, we proceed with production, lead time to complete is typically 10 weeks unless there are long lead items for the battery pack.

- If the samples need to be changed /modified, we will need to go through the proof process again with the updates prior to producing the next round of samples. (following the above timelines)

Standard Lithium Battery Pack Development Timeline Explained

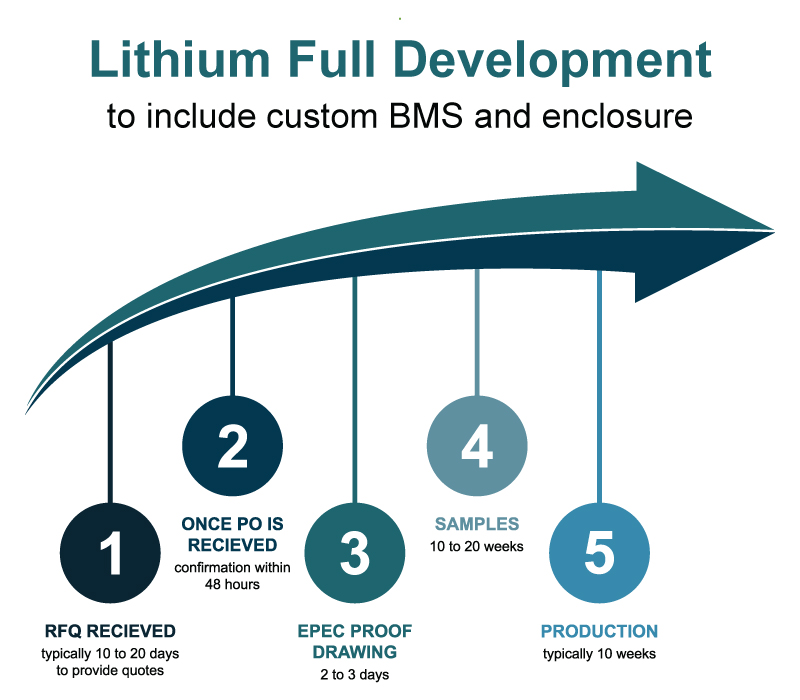

Non-Standard Lithium Battery Packs

Full development to include custom BMS and enclosure.

- RFQ received, typically 10 to 20 days to provide a quote, depending on the complexity of the design.

- Once a PO is received, it will be entered and confirmed to the customer within 48 hours.

- All battery projects need to begin with samples for the customer to receive, test, and approve. The sample quantity is determined by the customer during the quote process.

- The sample process begins with an Epec proof drawing created and submitted to the customer for approval before assembling sample/s batteries. This will take anywhere from 2 to 3 days, depending on the complexity of the battery.

- The proof is then submitted to the customer for their design review for approval to proceed with or changes they may want. Typically, the customer will provide approval or feedback within 3 to 5 days, and if edits or changes are needed, the proof is revised, resubmitted for approval again.

- With the proof approved, we will proceed with the determined number of samples; lead time will be contingent on PCBA design and component availability for samples. The housing will also require collaboration and approval on the design before proceeding.

- The PCBA and enclosure design and approval for samples are very much customer-dependent, so timing varies.

- Once approved, we proceed with samples. The lead time can range from 10 to 20 weeks, depending on the design, component availability, and is typically provided with 3D printed enclosures.

- The customer receives the completed samples and will need to perform their review and /or testing to provide a formal approval to proceed with the production quantity. This process is very undetermined, with some customers doing a quick bench-level test while some customers must install it in their device or equipment to then run through extensive testing before they can determine that the battery pack is acceptable. This customer review for the approval step can take anywhere from 1 day to several months, depending on the testing needed.

- If the battery pack is approved, we proceed with production, lead time to complete is typically 10 weeks unless there are long lead items for the battery pack.

- If the samples need to be changed /modified, we will need to go through the proof process again with the updates prior to producing the next round of samples. (following the above timelines).

Non-Standard Lithium Battery Pack Development Timeline Explained

DOT /UN38.3 Certification

- All lithium batteries require DOT /UN38.3 certification to manage production shipping. Only after sample approval can this be completed.

- A sample lot of 17 batteries must be assembled, which is an 8- to 10-week lead time.

- The samples are then deployed to the test agency to begin the testing and take approximately 6 to 8 weeks to complete.

- An electronic draft cert will be provided in about 8 to 10 weeks.

- The draft cert needs to be reviewed by the customer or a customer representative and approved to then formalize the cert, adding about another week.

- Total lead time – 14 to 16 weeks.

DOT UN38 3 Certification - Battery Pack Development Timeline Explained

UL2054 Certification

- With design confirmed and locked in, a sample lot of 55 batteries must be assembled that will be used for destructive testing. Typically, 8 to 10 weeks to produce.

- The samples are then deployed to the test agency with all associated specs and technical data to begin the cert testing – the testing takes approximately 12 to 14 weeks to complete.

- An electronic draft cert will be provided in about 12 to 14 weeks.

- The draft cert needs to be reviewed by the customer or a customer representative and approved to then formalize the cert, adding about another week.

- Total lead time – 20 to 24 weeks.

UL2054 Certification - Battery Pack Development Timeline Explained

IEC62133–2 Certification

- With design confirmed and locked in, a sample lot of 33 batteries must be assembled that will be used for destructive testing, typically, 8 to 10 weeks to produce.

- The samples are then deployed to the test agency with all associated specs and technical data to begin the cert testing – the testing takes approximately 8 to 10 weeks to complete.

- An electronic draft cert will be provided in about 8 to 10 weeks.

- The draft cert needs to be reviewed by the customer or a customer representative and approved to then formalize the cert, adding about another week.

- Total lead time – 18 to 20 weeks.