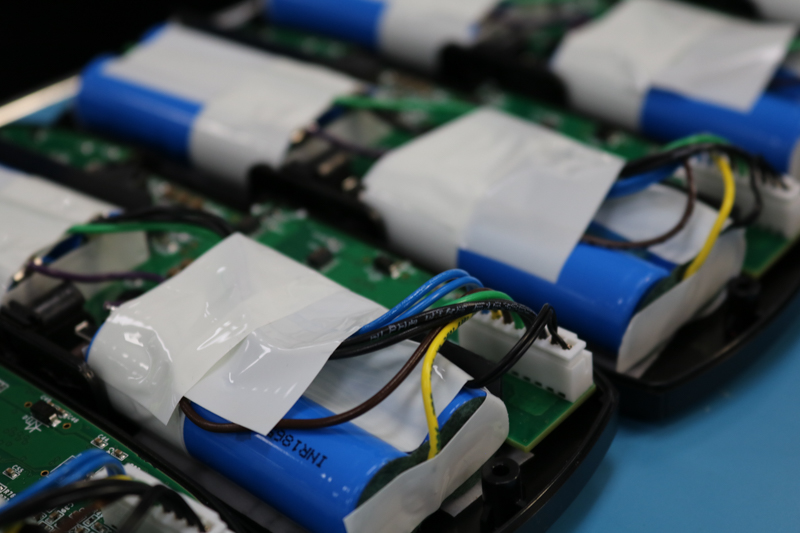

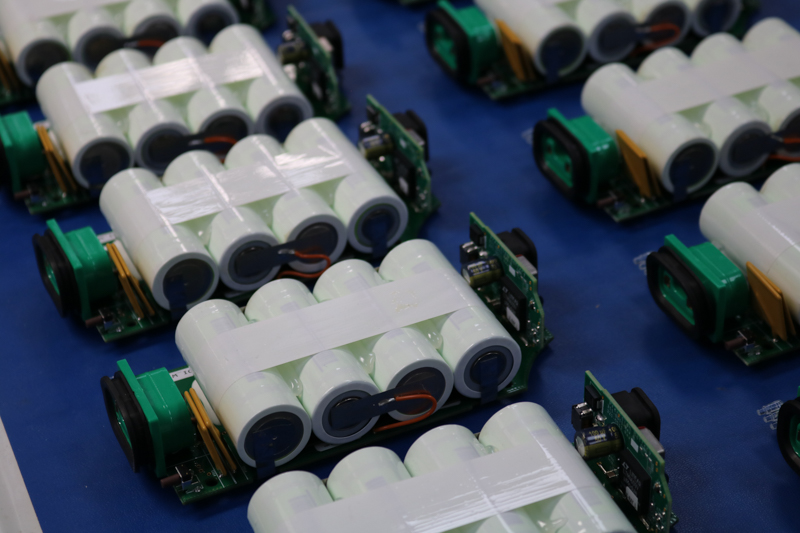

Custom Lithium Battery Packs

Epec Engineered Technologies is a premier source for lithium battery packs, providing both primary and secondary lithium solutions. Epec offers a wide range of products and services to cater to the needs of customers across different industries. Here we will discuss the reasons why Epec is the best source for lithium battery packs and why customers should choose Epec for their custom battery needs.

Lithium batteries have become an essential power source for a wide range of applications. Epec has a tremendous amount of application experience which includes consumer electronics, medical devices, industrial equipment, portable devices, and military applications. As the demand for lithium batteries increases, the need for reliable and high-quality battery packs also grows. Epec has been in the battery industry for many years and has the experience and expertise to deliver innovative and reliable battery solutions.

Lithium Battery Capabilities

Epec offers a wide range of lithium battery solutions, most specifically custom battery packs that utilize both primary and secondary lithium batteries, which are two types of rechargeable batteries that differ in their chemistry and construction. While both types of batteries use lithium as their primary active material, they have distinct characteristics and are used in different applications.

By now, most people are aware that lithium batteries are known to be volatile and can catch fire or explode if not handled properly. Therefore, ensuring the safety of the battery pack is of utmost importance when designing a lithium battery pack. Epec will ensure that the battery pack is designed with the proper safety features, such as overcurrent protection, overcharge protection, and thermal management systems.

Primary Lithium Batteries

Primary lithium batteries, also known as non-rechargeable lithium batteries, are designed for one-time use, and cannot be recharged. They are often used in applications where long-term reliability and stability are critical, such as in military and aerospace applications. Primary lithium batteries have a higher energy density and a longer shelf life compared to other battery chemistries.

Primary lithium batteries use lithium metal as the anode and a non-aqueous electrolyte to conduct ions between the anode and cathode. The cathode material used in primary lithium batteries can vary, but common materials include manganese dioxide, thionyl chloride, and sulfur dioxide. Primary lithium batteries have a higher voltage and energy density compared to secondary lithium batteries, but their capacity is limited.

Best Applications for Primary Lithium Batteries

Primary lithium batteries are best suited for applications that require long-term reliability and stability. These batteries are commonly used in:

- Military and aerospace applications

- Medical devices, such as pacemakers and hearing aids

- Remote sensors and monitoring devices

- Emergency backup systems

- High-performance flashlights

Secondary Lithium Batteries

Secondary lithium batteries, also known as rechargeable lithium batteries, are designed to be recharged and used multiple times. They have a lower energy density and a shorter shelf life compared to primary lithium batteries but have a higher capacity and are more cost-effective over their lifetime.

Secondary lithium batteries use lithium ions as the active material, which are transferred between the anode and cathode during charging and discharging cycles. The anode material used in secondary lithium batteries is typically graphite or a lithium metal oxide, while the cathode material can vary, depending on the application.

Common cathode materials used in secondary lithium batteries include:

- Lithium cobalt oxide (LCO): Used in high-performance applications, such as laptops and smartphones.

- Lithium manganese oxide (LMO): Used in power tools.

- Lithium iron phosphate (LFP): Used in stationary energy storage systems and medical devices.

- Lithium nickel manganese cobalt oxide (NMC): Used in grid-scale energy storage systems.

Best Applications for Secondary Lithium Batteries

Secondary lithium batteries are best suited for applications that require high capacity, rechargeability, and cost-effectiveness. These batteries are commonly used in:

- Consumer electronics, such as smartphones, laptops, and tablets

- Power tools and other cordless devices

- Energy storage systems, such as grid-scale storage and home energy storage

- Medical devices, such as wearable devices and insulin pumps

Lithium Battery Management Systems

Epec's battery management systems (BMS) provide advanced battery protection and monitoring capabilities, ensuring the safe and reliable operation of battery packs. The BMS can also optimize battery performance, extending the battery's lifespan and reducing maintenance costs. Epec's custom battery packs are designed to meet specific customer requirements, providing the perfect solution for unique applications.

Development of Lithium Battery Packs

Developing a lithium battery pack requires expertise in many areas, including electrical engineering, mechanical engineering, and chemistry. A battery pack must be designed to meet the requirements of the application, including voltage, current, energy density, and size. The battery pack must also be designed to ensure the safe and reliable operation of the battery cells. We have many different resources on this process and what customers need to consider when developing custom battery packs such as:

Epec's experienced engineering team has the expertise to design and develop battery packs for a wide range of applications. It is involved in every aspect of the battery pack development process, from the initial concept to final production. Epec uses state-of-the-art tools and technologies to ensure the highest quality and reliability of its battery packs.

Low Cost and Domestic Battery Pack Production

Epec offers both offshore and domestic production capabilities to cater to the needs of customers across different industries. Our offshore production facilities provide cost-effective manufacturing solutions, enabling customers to reduce production costs without compromising quality. Our offshore facilities are located in Asia, providing access to a vast network of suppliers and manufacturers.

Epec's domestic production facility is located in the Boston, Mass., area and provides fast turnaround times and high-quality manufacturing services. Epec's domestic facilities are equipped with the latest manufacturing technologies and tools, enabling us to produce high-quality battery packs at competitive prices, and are ITAR and ISO/IEC 27001:2013 certified.

Financially Strong Company with Many Years of Experience

Choosing a financially strong company with many years of experience is crucial when selecting a lithium battery pack supplier. Epec Engineered Technologies has been in the battery industry for many years and has a proven track record of delivering high-quality battery solutions. Epec's financial stability ensures that customers can rely on Epec for their long-term battery needs.

Epec's Experience in the Battery Industry

Having worked with customers across different industries, providing customized battery solutions for their specific needs means that our engineering team has the knowledge and expertise to solve even the most challenging battery design problems.

Epec's commitment to quality and customer satisfaction is reflected in its ISO 9001:2015 certification. Our quality management system ensures that every battery pack meets or exceeds the customer's requirements and expectations.

Need Help with a Custom Lithium Battery Pack?

From design to production, our team of experienced engineers at Epec is here to help you design a custom lithium battery pack that exceeds your needs.

Request a Quote Request Design Support Request More Information