Quality Assurance Capabilities

Quality is one of the most important factors when designing high reliable user interface solutions. The mission of our engineering team is to design and manufacture products that meet and exceed our customer’s life cycle testing requirements.

Not only should your Human-Machine Interfaces (HMI) be rugged enough to withstand it’s operating environment, it should also last for the duration of the equipment lifecycle. For example, a dome found in a membrane switch construction should last more than 1 million cycles. With the proper life testing bench we are able to life test multiple types of user interface buttons we manufacturer to provide the best quality assurance. Should you require life cycle validation, we have the proper tools and equipment to accurately test and document the life cycle capability of all our products.

See this blog post to learn more about how we develop user interface functional test schemes.

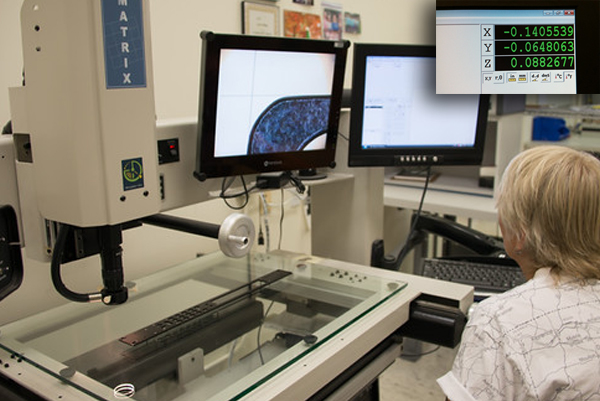

Micro Vu Matrix Digital Optical Comparator

The Micro-Vu Matrix Video Measuring Machine is a non-contact measuring solution for large parts. The Matrix Video includes a zoom lens, profile & surface lighting, and Q-16 Metrology. The Matrix handles measuring parts up to 1200mm with ease. Micro Vu Matrix Digital Optical Comparator complete with metrology software, and 24 by 18 inch measurement capability.

Typical drawings/prints have tolerances that go out to ±3 decimal places (0.000). With our Micro Vu vision measuring system, we have the capability to measure out ±7 decimal places (0.0000000), which is unheard of in inspection measuring capabilities. This allows our customers to be assured their product has tight tolerances, the equipment can measure it accurately while providing statistical data if required.

Stereo Zoom Microscopes

We utilize 12 Stereo Zoom Microscopes along with a Fiber Optic Ring Illuminator. These microscopes are used for detailed assembly, soldering, and inspection. It verifies the solder joints meet all requirements for IPC-A-610 inspection criteria and also assures accurate assembly of the smallest components.

Wagner FDIX Digital Force Gauge

The Wagner FDIX Digital Force Gauge is used to measure tension and compression forces. It accurately measures the force to actuate any type of human-machine interface (HMI) button. This is beneficial in applications that can aid in setting the right force required for your HMI.

Minolta CR-400 Colorimeter

The CR-400 Chroma Meter is a handheld portable measurement instrument designed to evaluate the color of objects, particularly with smoother surface conditions or minimal color variation. It accurately identifies color characteristics in objects, determines color differences between objects, and provides pass/fail assessments to immediately determine if the sample meets the defined standard. This makes the CR-400 ideal for color inspections of food, building material, plastic, dermatological applications within quality control, quality assurance, and R&D fields.

Through standard or customized evaluation formulas this high accuracy reliable colorimeter helps users control the color quality, consistency, and appearance of their products in a more efficient streamlined process internally and throughout the supply chain.

Ohaus Precision Digital Gram Counting Scales

We have two Ohaus Precision Digital Gram Counting Scales which are used for multipurpose industrial weighing applications in which value is important but quality, durability, and functionality cannot be compromised. The scales are equipped with seven application modes that can provide results for many industrial weighing and measurement needs.

The scales are used to accurately weigh bulk pack shipments to keep accurate inventory of small components and new production samples if part weight is critical.

Keyboard Life Test Bench

The contact tester is designed to press and depress buttons, keypads, and membrane switches. The tester can be used for contact testing as well as general mechanical and cosmetic button wear.

Calipers and Gauges

When it comes to quality assurance we utilize an assortment of digital height, caliper, plug, radius, thread, and force gauges. All gauges are on positive recall system that is fully automated. Calibrations are performed by an A2LA accredited lab on specific intervals based on the gauge type and usage.

State-Of-The-Art Testing and Quality Assurance

For HMI solutions engineered for ruggedness and longevity, trust our state-of-the-art testing and quality assurance measures. From life cycle validation to ultra-precise tolerances, we've got you covered.

Request a Quote Request Design Support Request More Information