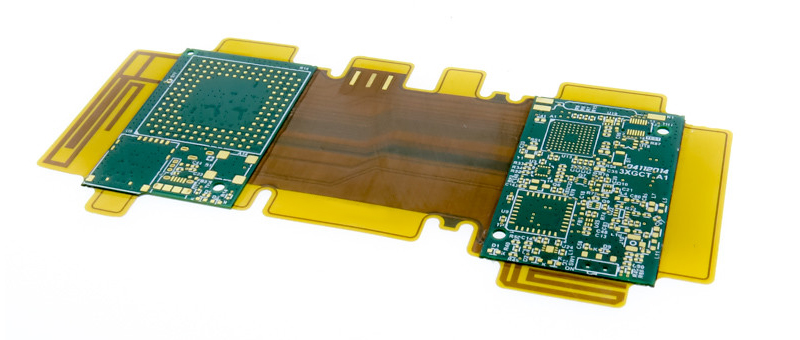

Rigid-Flex PCB Designed For Asset Protection Systems

Challenge

Epec was approached by a leader in asset protection systems to help them with issues they were having with their current rigid-flex circuit. The initial design review found that the yield rate was very low, a lot of rework was needed, and there were several failures with the design of the rigid-flex PCB.

The design consisted of a separate flex circuit and a rigid board and required the rigid board module to be soldered onto the surface of the flex circuit. The rigid board had a large number of castellated holes around its perimeter that were then surface mount soldered onto the flex. These solder joints were difficult to achieve and required a large amount of hand touch up after assembly. There was also an opportunity to break these solder joints if the parts where not handled very carefully.

A general discussion with our Flex and Rigid-Flex Product Manager provided the customer several options on how to improve the design by providing basic information and capabilities on rigid flex circuit boards which the design would require.

Additionally Epec discussed how certain parts would be integrated together and what the material and construction of a typical rigid flex would look like. This was to ensure that the customer had and understood basic rigid-flex fundamental.

Solution

The customer decided to move forward and asked Epec to start a second generation of the initial rigid-flex design. This second revision would address the initial problems our engineering team found in the initial design review.

Both the client’s engineering team and Epec’s worked to finalize Gerber data file sets to confirm that the design met all IPC specifications and that it was in fact manufacturable. It was also certified that the new design would have a good yield rate and once the design was approved it was sent into production.

The revised design integrated the rigid board and the flex into a rigid–flex design which completely eliminated the above assembly process and the soldering issues and also made the design much more robust for handling purposes.

Result

All of the customer’s goals of evolving the design to a much higher level of manufacturability, improved reliability, and the complete removal of the initial problems and failures were met. The new revision was a substantial improvement. The cost of the finished unit went down and their biggest issue with assembly process and difficulties with it were virtually eliminated. The previous generation required a high percentage of rework on the assembled parts to overcome the design challenges that it had. The new design went through the assembly process with a 100% yield rate.

Need Help with a Rigid-Flex Circuit Board Design?

From design to production, our team of experienced engineers at Epec is here to help you design a production ready rigid-flex circuit board for your application.

Request a Quote Request Design Support