Advancing Heater Coil Design and Production for a Repeat Customer

Challenge

A repeat Epec customer approached our team with a request that came directly through Epec’s CEO, after one of their engineers reached out seeking technical assistance. The company had been developing a prototype for a custom heater coil, but needed support refining the design and scaling it for production.

While they had extensive internal engineering expertise, their facilities lacked the specialized equipment and process capability necessary to develop and test a multilayer heater coil assembly. They needed help completing the R&D phase, validating the design through prototypes, and preparing for full-scale manufacturing.

The customers’ goals were twofold:

- Finalize a reliable, manufacturable coil design that would integrate seamlessly into their other assemblies.

- Transition from early-stage R&D into repeatable, higher-volume production with the ability to scale as demand increased.

The challenge lay in balancing precision, performance, and manufacturability. The prototype’s construction required consistent adhesion and layer bonding between copper and polyimide materials, something that demanded both technical expertise and controlled process development. Their engineers knew that achieving uniformity in trace patterning, layer alignment, and thermal bonding would be difficult without Epec’s experience in flexible heater manufacturing.

Solution

Epec’s engineering team collaborated directly with their lead engineer, reviewing models and drawings to gain a complete understanding of the design requirements. The partnership began with prototyping and process experimentation using Epec’s in-house resources.

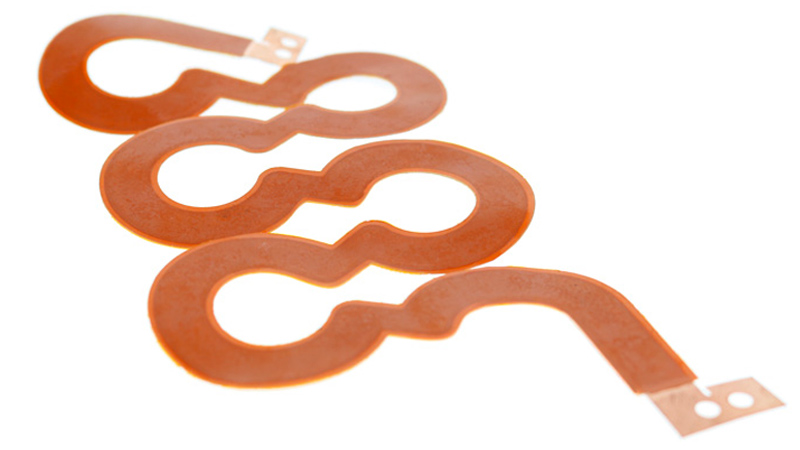

The early development stage involved machining copper and manually cutting polyimide layers to precise dimensions. Epec’s engineers then experimented with several methods for layer bonding, ultimately developing a reliable process that stacked polyimide, copper, and polyimide films before heat pressing them into a single laminated structure.

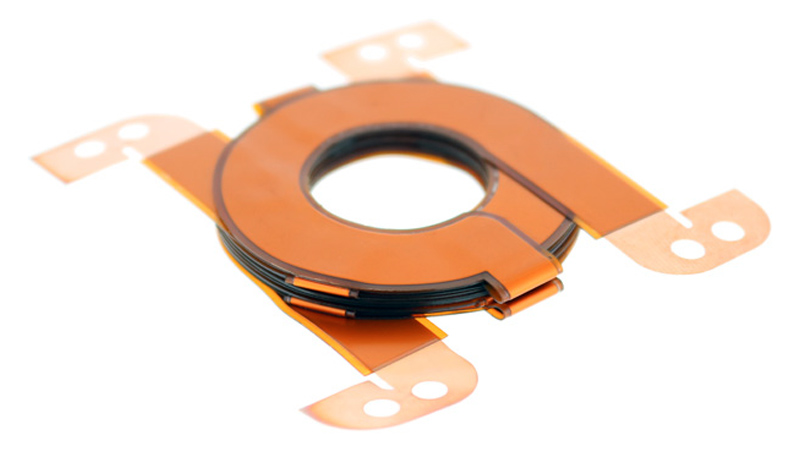

The next stage consisted of folding these laminated structures into a compact coil. The folding of the coil layers required precision and due to the size constraints of where this coil would be installed. Another challenge would be determining the perfect pressure and temperature that would be applied to these coil layers so that when compressed, they would form into one folded coil. Epec’s engineers trialed numerous combinations of pressures and heat until they were able to form the heater coil that is used today.

Both of these processes required multiple rounds of refinement. The team iterated through several prototypes, adjusting critical parameters such as:

- Polyimide thickness to balance flexibility and heat transfer.

- Outer dimensions to improve fit and alignment within the customer’s assembly.

- Bonding temperature and pressure to achieve consistent lamination quality.

Each revision was evaluated with their engineering team to verify that performance and form fit met the project’s needs. Once the design was finalized, Epec transitioned from prototype development to production planning.

The next phase focused on establishing a scalable manufacturing process. Production quantities were initially limited, allowing for process validation and repeatability checks before ramping up. As part of this process, Epec introduced an optimized workflow where coil layers were manufactured offshore to control material costs while final assembly and form-fit validation were performed at Epec’s U.S. facility.

This hybrid approach provided both cost efficiency and quality assurance. By keeping assembly and process control internal, Epec maintained oversight of critical steps like folding, inspection, and hi-pot testing. Meanwhile, offshore production helped reduce lead times and material costs for the copper and polyimide components.

To further improve throughput, Epec began developing an automated assembly method to replace some of the manual steps in the folding and bonding process. This initiative aims to increase production speed, reduce labor time, and enhance consistency as order volumes continue to rise.

Result

The collaboration resulted in a fully functional coil design that met all technical and dimensional requirements. Through Epec’s iterative R&D process, the customer received not only a refined prototype but also a clearly defined path to full-scale production.

The daisy-chained coordination between design, prototyping, and manufacturing ensured that the product was both technically sound and manufacturable at scale. The successful completion of multiple prototype revisions demonstrated Epec’s flexibility in adapting to changing design needs while maintaining engineering discipline throughout the process.

Although the project is still progressing through expanded production runs, early results have been positive. The customers engineering team have expressed confidence in the quality, reliability, and repeatability of the coil assemblies produced through Epec’s process. The project has also reinforced the value of the long-standing relationship between the two companies.

By combining in-house engineering, flexible manufacturing options, and collaborative problem-solving, Epec enabled them to move from a concept-level prototype to a scalable production-ready design. The work highlights Epec’s role not just as a supplier, but as an engineering partner capable of supporting customers through every stage of product development, from early design challenges to production-scale efficiency improvements.

As automation efforts continue and production volumes increase, Epec remains committed to advancing both process capability and throughput for its heater line. This ongoing partnership stands as a strong example of how Epec’s technical depth, responsiveness, and collaboration-first approach drive long-term customer success.

Need Help with a Custom Flexible Heater Project?

Whether you’re in the early stages of R&D or preparing to scale a complex flexible heater, our engineering team is here to help. We work as an extension of your design group to solve challenges around material selection, lamination processes, form-fit constraints, and production-ready manufacturing.

Contact us today to discuss your design requirements and learn how we can support your next project.

Request a Quote Request Design Support