When an Off-The-Shelf Connector Doesn’t Meet Your Cable Assembly Design Objectives

Challenge

A design engineer was looking for help with a custom cable assembly yet he had difficulties finding the ideal off-the-shelf connector. The first step was to learn more about the application, current concept, and what the design objectives were.

It became apparent that the customer was early on in the development process as they were not locked in to a specific connector design. Ultimately, their challenge was they couldn’t find an off-the-shelf connector. They were looking for a connector with 2-pins and a 4mm pin pitch that also had the required pin geometry.

An agreement was made, and we began to mature the concept and explore design options. An off the shelf connector was selected from a known manufacturer but it was less than ideal and required modifications once purchased.

The pin pitch on the connector was 2 mm, which required sourcing a 3-pin connector and cut the center pin to achieve the 4 mm pitch requirement. Also, the pin’s diameter and length were issues since it would interfere with the mating housing and required a redesign to the customers main assembly. It was clear that we needed to think outside the box for this project to be successful.

Solution

We continued exploring options and proposed a custom connector to be tooled up. This option met all design requirements and program objectives and the tooling investment necessary was well within the customers budget. At this point additional funding was awarded to further mature the concept and build prototypes.

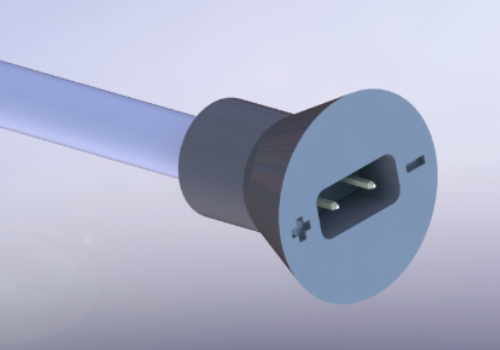

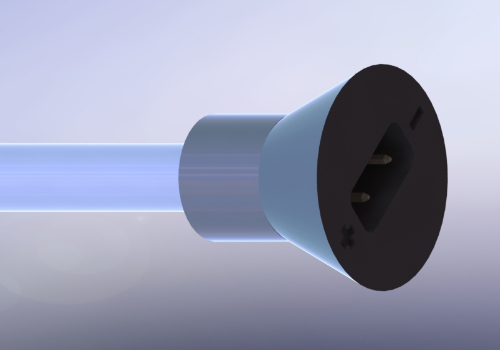

The prototype met the 4mm pin pitch requirement, had the correct quantity of pins (without any modification or cutting of pins), and was the exact pin diameter and length the customer needed for this solution. This design consisted of an inner mold of a hard TPE, custom machined pins crimped and soldered to the conductors, and a black PVC overmolded connector housing. The engineering team was even able to design the tool so the pin polarity (“+” & “-“) was over molded on the connector face.

Result

The customer continued to develop their system with our prototype cable assembly and determined that the newly developed custom connector needed a few minor modifications.

The most notable was the overall pin length needed to be extended to facilitate the appropriate engagement depth. The pin length change simply would not have been possible if the off the shelf connector was selected. While custom connectors on cable assemblies may have a higher upfront investment when compared to an off the shelf solution, these designs are truly custom and help the customer realize the exact configuration necessary to bring their product to market. Since there is no obsolescence risk or egregious lead-times for these custom tooled connectors, sourcing risk can be significantly reduced.

In summary, a custom tooled connector may not be a good fit for every cable assembly design project. However, if your design features a unique requirement and an off the shelf connector doesn’t work, consider a custom tooled connector and cable assembly.

Need Help With A Custom Cable Assembly Design?

From design to production, our team of experienced engineers at Epec is here to help you design a production ready cable assembly for your application.

Request a Quote Request Design Support