Creating a Practical Solution for Long Flex Circuits with Thin Traces

Challenge

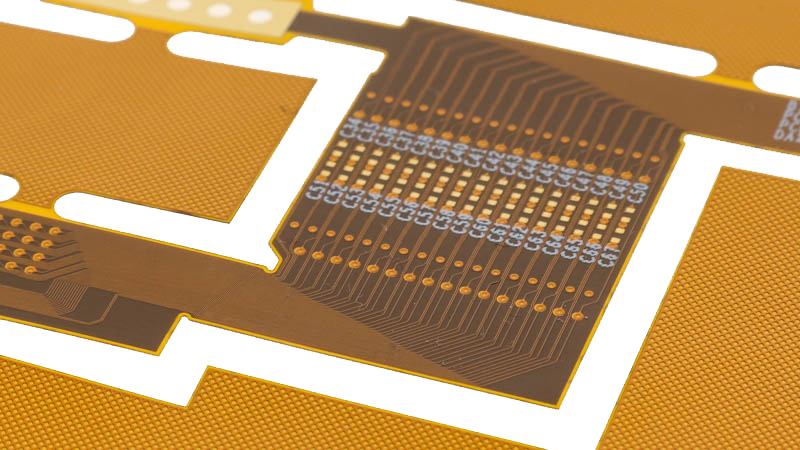

Epec was approached by a long-standing customer who was facing new design challenges in their flexible circuit requirements. Traditionally, their applications had been served with standard trace widths and manageable circuit lengths. However, as their products evolved, they began to require much longer flex circuits with thinner trace widths.

This combination, long lengths paired with very fine traces, introduced significant manufacturing difficulties. In the etching process, thin traces over large areas become highly susceptible to damage. Maintaining trace integrity without sections etching away is extremely difficult, and in many cases, nearly impossible with existing production methods. The customer recognized this limitation and came to Epec with two possible needs: either find a way to produce these longer, thinner flex circuits reliably, or suggest an alternative approach that would still achieve their performance goals.

Complicating matters, this was not a request that other manufacturers were willing to take on. The customer had already approached several other suppliers and received rejections. Some declined outright, stating the design was not manufacturable, while others did not provide constructive feedback or potential alternatives.

With the project at risk of stalling, the customer relied on Epec’s engineering expertise and collaborative approach to evaluate the challenge from a fresh perspective.

Solution

After carefully reviewing the design requirements, Epec’s engineering team determined that producing a single, extremely long flex circuit with ultra-thin traces was not feasible with current manufacturing technology. Instead of dismissing the project, Epec proposed a creative workaround that would maintain electrical performance while avoiding the risks of trace loss during etching.

The solution was to break down the design into multiple shorter flexible circuit boards that could be connected using a daisy-chain configuration. By linking these smaller flex circuits together, the customer could still achieve a continuous and unbroken connection from point A to point B without relying on a single, excessively long piece. This approach balanced manufacturability with performance, ensuring that the trace widths could remain within stable tolerances.

To support this strategy, Epec worked closely with the customer to validate the daisy-chain method as a practical solution. Our engineers explained the technical reasoning behind the approach and demonstrated how the configuration could deliver the same electrical continuity required by their design. Rather than presenting a “yes or no” answer, Epec provided a pathway forward that preserved the customer’s design intent while remaining realistic in terms of production capabilities.

This proactive problem-solving also underscores one of Epec’s core strengths: we don’t just point out limitations, we offer alternative solutions. Where other manufacturers had walked away, Epec leaned in and worked collaboratively with the customer to reshape the design into something that could be built and delivered reliably.

Result

With Epec’s support, they achieved a more cost-effective and scalable battery pack and charger solution than would have been possible with their in-house team alone. Our partnership reduced long-term component costs and accelerated the development timeline by bridging the gap between their mechanical focus and the electrical expertise required for this new product area.

By leaning on Epec’s design experience and global supplier network, they were able to expand into a new technology space with confidence, without diverting critical internal resources away from their primary mission of advancing medical devices.

Looking to Maximize What’s Possible in Flexible PCB Design?

Our experienced engineers work with you from the earliest design stages through full production to ensure your flexible PCB meets performance and reliability goals.

Request a Quote Request Design Support