Reverse Engineered Battery Pack Design for Handheld Detection Device

Challenge

Epec was approached by a leading manufacturer of premium ESD control related instruments and handheld detection devices. They were currently working with a broker for their battery packs, but over the past two years had been experiencing serious delays with the prototyping, the shipments, and any communication to even determine what the delays were. Their product delivery was not consistent, which was causing them delays to their end customers and overall frustration in general, so they were looking for an alternative battery pack supplier.

They found us through our website, and they were impressed with our product offerings and battery experience, and the amount of technical content we had available online. They saw several case studies and photos of different battery packs we have manufactured in the past for various other companies in their industry. They were aware that we had the technical experience, so they reached out to us for guidance on helping them.

The request they submitted online was filtered in through our inside sales team in Virginia and passed over to out outside sales team to engage with the customer. The opportunity was then vetted with the battery product manager to determine if the request is applicable.

Solution

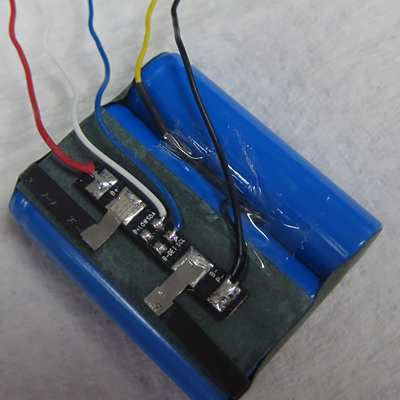

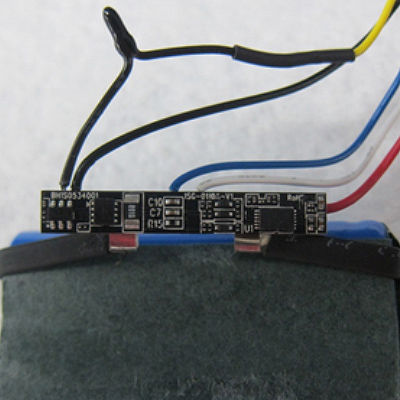

This project took a little while, because once we engaged with them in conversations, we learned that they didn't have any specifications or assembly drawings because they weren't able to obtain them through the broker or the actual factory in Asia was building the battery. So, we had to basically reverse engineer this battery pack through photos and several Zoom meetings. Once we were able to obtain enough information on the battery pack and application with photos of the device and the housing cavity, we were able to begin to budgetarily quote the pack. Once the customer approved the quote, we began to reverse engineer it.

This project followed our standard process of having meeting with both the customers engineering team along with our battery product manager and engineer team. With this reverse engineering project, both our Asian engineering team and domestic engineers in New Bedford MA were needed to help in the development of this battery pack. Along with the battery, there was also a wire harness and connector that goes with it that also had to be reverse engineered.

We were able to obtain enough information through several meetings. Photos and a physical example of the current battery pack were also provided by the customer. During our meetings, we talked in depth about the application and work closely with the customer to reverse engineer this.

Once we had a complete data package, including detailed drawings that the customer also received, we were able to start building prototypes. The customer was then sent samples to evaluate to approve form, fit and function of the pack, which ultimately then went on to production.

Result

We were able to reverse engineer this battery pack with limited information, specs, or a detailed drawing. The customers target pricing was met as well. Another huge benefit we provided that a broker could not, was utilizing our inventory stocking programs. This allowed them to have product in our warehouse ready to be shipped to them on schedule releases, or to accommodate pull-ins in case of an increase in demand.

The customer now has a full team of resources at Epec, include our quality department, engineering, customer service, and the product manager to help manage their business and assist with any technical questions or changes going forward. This level of expertise and responding with a sense of urgency was a value-added service Epec offers, that a broker cannot match.

Looking for a Custom Battery Pack for Portable Device?

From design to production, our team of experienced engineers at Epec is here to help you design a production ready custom battery pack for your portable device.

Request a Quote Request Design Support