Reverse Engineered Membrane Switch Assembly

Challenge

A fast growing company has been making high-end conformal coating systems, fluid dispensing solutions and custom automation products for 20 years. Their products are used in industries including solar, semiconductor packaging, printed circuit board assembly, medical device manufacturing, and consumer electronics.

The company previously relied on a small, local company to provide the membrane switches and printed circuit boards used in their selective coating system machines. When the small company went out of business, they needed a new membrane switch and PCB supplier, but had no documentation, engineering drawings, or data on the manufacturing of these products. The company turned to Epec to reverse-engineer these two equipment critical products from scratch.

Solution

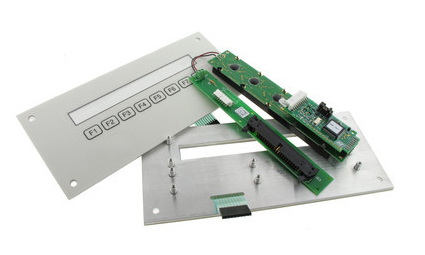

The company sent one of their old membrane switches they wanted manufactured to Epec, where the complete user interface was taken apart and dissected down to the graphic overlay, circuit boards, power supply and LCD.

While the power supply module and LCD screen could be obtained off the shelf, the PCB inside the membrane switch needed to be reconstructed without any documentation about how it was originally made. Epec created the entire document package de novo, including the full Gerber package, hole sizes, and tolerances. Obsolete connectors in the sample membrane switch were also crossed in order to create a functional PCB able to replace its predecessor.

As part of their value-add services, Epec manufactured not only the PCB that was needed, but also the corresponding fully registered graphic overlay and dome switches. The end product was a complete aluminum backed membrane switch that was tested for continuity.

By manufacturing the entire product, including the circuit board and corresponding graphic overlay, Epec allowed the customer to avoid the hassle of multiple assembly steps and to receive a membrane switch that could be conveniently plugged in to their machine for immediate use.

Result

The customer now has a world class source for fully functional aluminum backed membrane switches for their selective conformal coating system machines.

Need A Custom Membrane Switch?

From design to production, our team of experienced engineers at Epec is here to help you design a production ready membrane switch solution for your application.

Request a Quote Request Design Support