Flex & Rigid-Flex Circuit Capabilities

Below are our flex and rigid flex circuit capabilities, along with available materials substrates and adhesives. We also offer an extensive range of solder mask and coverlay products as well as various surface and finishes treatments.

Our Capabilities Include

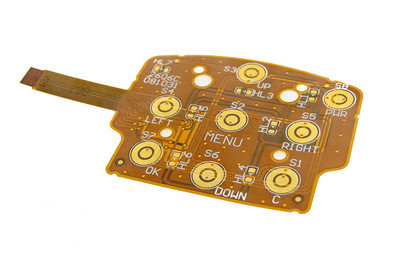

Single or Double-Sided Flex Circuits

Flex PCB design simplifies assembly, minimizes interconnect errors, and improves reliability. Low-cost manufacturing available. Thru-hole, reverse bare, floating fingers/sculpted circuits, ZIF termination are available.

Multilayer Flexible PCBs up to 20 layers

High circuit density flexible PCBs can handle multiple conductive layers that can include EMI shielding, through-hole assembly, embedded resistors, controlled impedance, and other specified electrical requirements. Effective use of ground/shield planes, appropriate connector interfaces, and matched-impedance flex circuits delivers optimal high-speed signal integrity.

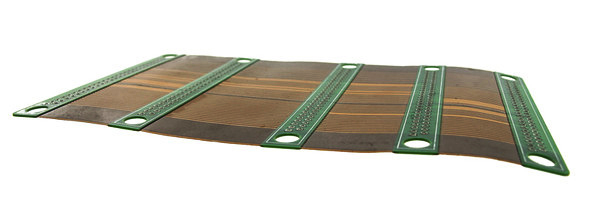

Multilayer Rigid-Flex up to 20+ layers

Three-dimensional capabilities of rigid-flex designs create optimal application solutions when extreme space limitations exist along, allowing the end user to process multiple board and cable terminations in one pass of the reflow process.

Lines and Spaces

Down to 0.0025" and vias down to 50 microns: using the smallest component size and pitch improves electrical performance, signal integrity, and thermal performance when routing space and via diameters need to be minimized.

Installation of Connectors, Pins, Contacts, SMD, & PTH Component Assembly

Available as well as in circuit testing, conformal coating, and electrostatic protective packaging. IPC 6012/6013 Class I, II, III, types 1-4ISO 9001, AS9100 certified.

Stiffener Supported Areas (using FR-4, Polyimide, etc.)

Thermally bonding with heat and pressure or using a PSA (Pressure Sensitive Adhesive): the method used to attach the stiffener will depend upon the configuration and or location of the stiffener(s). The specific PSA (e.g. 3M Tape, 3M467, or 3M9077) will depend on whether the flex PCB will be subjected to an automated reflow cycle and/or what material it is to be adhered to.

Blind & Buried Vias

Many of today's rigid-flex circuit designs utilize the same high-density components found in rigid PCB designs. This requires the use of blind and/or buried vias to allow the signal lines to be routed out from within the high-density components or the high-density areas of the design.

Controlled Impedance

With increasing signal switching speeds, short signal transition times, and high clock rates of the highest technology ICs, traces need to be designed to minimize electrical reflections. Controlled impedance signal transmission in printed circuit boards, both flex and rigid, requires PCB laminate materials to be uniform in both thickness and electrical properties along with having an etching process that can be controlled down to +/- 1% of variation of signal thickness and shape. This is especially important as the goal of a flex or rigid-flex circuit is to improve the signal transmission through elimination of cross-sectional changes to conductors (connectors, cable, solder connections).

EMI/RF Shielding

Copper, silver ink, and shielding films: shielding is instituted when an application requires limits in electromagnetic and/or electrostatic interference. Protective shielding, whether an etched or screened pattern of material, will reduce noise and controls impedance of signal lines.

Circuit Size

Circuits up to 24" in length or greater, depending upon technology.

Substrates

- Polyimide: 1 - 3 mil

- Epoxy

- Teflon

Copper

- Rolled Annealed Copper

- Electro - Deposited

Flex Circuit Adhesives

- Modified Acrylic

- Modified Epoxy

- Pressure Sensitive (PSA)

Solder Mask / Coverlay

A coverlay serves as the same function as soldermask that is used on a rigid printed circuit board. The difference with a coverlay is the added element of flexibility and durability it provides to the flexible circuit board.

- Polyimide Coverlay: 1/2 mil to 2 mil

- Flexible Liquid Photoimagable (LPI) Soldermask

See our blog post titled what is a flexible circuit coverlay to learn more.

Surface Treatment & Finishes

- ENIG (Electroless Nickel - Immersion Gold)

- Immersion Silver

- Hard Gold

- HAL (Non-leaded, RoHS)

- HAL (Leaded)

Stiffeners

Stiffeners are typically used to reinforce selective areas of flexible circuitry for component support, durability and mounting. They can also be used for strain relief and heat dissipation. Bonding materials include pressure sensitive adhesive (PSA) and Temperature sensitive adhesive (TSA).

Stiffener Materials:

- Unclad FR4 / G10

- Polyimide

Stiffener thickness is determined by your actual needs. Typical stiffeners thickness' range from 0.005" to 0.062".

Maximize Performance with Our Comprehensive Flex and Rigid-Flex Circuit Solutions

From single-sided flex circuits to multi-layer rigid-flex designs, we meet all your needs for electrical performance, miniaturization, and reliability. Our AS9100 and ISO 9001 certifications guarantee quality. Contact us today to discuss your project requirements.

Request a Quote Request Design Support Request More Information