Rigid-Flex PCBs for Industrial Control Applications

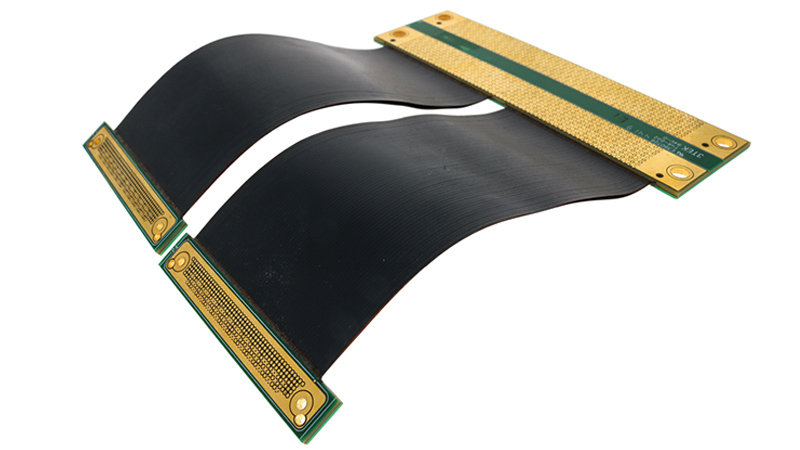

Rigid-flex printed circuit boards are popular in industrial control applications due to their mix of rigidity and flexibility. They offer the advantages of both rigid and flexible PCBs, making them ideal for various industrial uses.

Benefits of Rigid-Flex PCBs

Rigid-flex PCBs are favored in industrial control applications because they handle complex, high-density designs. These PCBs allow for a large number of components in a small space, offering greater design flexibility and higher component density than traditional PCBs. This results in efficient space use and a smaller overall footprint, crucial in industrial settings.

They can manage high current and voltage levels due to their unique construction, combining the strengths of both rigid and flexible PCBs. The rigid parts provide mechanical stability, while the flexible parts allow complex routing of signals and components, enabling high current and voltage handling.

Another key benefit is their durability in harsh environments. Industrial control applications often involve extreme temperatures, humidity, and other factors that can damage traditional PCBs.

Applications in Various Industries

Rigid-flex PCBs are used in a wide range of industrial applications due to their unique properties. Common uses include:

- Industrial Automation: Used in robotic control systems, motor control systems, and factory automation. They offer high-density interconnects in a compact form, essential for precision and reliability in tasks like assembly, inspection, and material handling.

- Oil and Gas: Applied in drilling, production systems, pipeline monitoring, and downhole instrumentation. Their combination of rigidity and flexibility allows them to withstand high temperatures, pressures, and harsh conditions.

- Instrumentation and Test Equipment: Utilized in oscilloscopes, signal generators, and spectrum analyzers. They meet stringent performance requirements, handling high data rates and frequencies with reliability and durability.

Why Choose Rigid-Flex PCBs?

- Signal Integrity: They offer excellent signal integrity with low insertion loss and impedance matching, crucial for accurate measurements.

- Compact Size: They allow for a compact form factor, integrating more functionality in a smaller space.

- Thermal Stability: They maintain structural integrity in extreme temperatures, ensuring accurate measurements.

While rigid-flex PCBs can be more expensive than traditional ones due to their complex construction, working closely with PCB suppliers like Epec Engineered Technologies can help customers understand the benefits and trade-offs. We provide guidance throughout the design and manufacturing process, ensuring the best technology for specific application requirements.

Flex and Rigid-Flex PCB Solutions for Industrial Control Applications

Optimize your industrial applications with rigid-flex PCBs. Consult with Epec today for expert guidance and tailored solutions.

Request a Quote Request Design Support Request More Information