Flex and Rigid-Flex PCBs for Medical Applications

The medical industry relies on dedicated professionals and advanced medical devices to save lives every day. As devices become more powerful, smaller, and portable, there is a growing need for circuitry that offers high capabilities while meeting medical regulations and standards. Rigid-flex and flexible printed circuit (FPC) from Epec provide dependable and reliable solutions.

Flexible Circuits: The Ideal Choice

Medical applications are constantly seeking greater functionality. Multilayer circuit boards can handle necessary control functions, but they also require flexibility and portability. Devices like blood glucose monitors, heart monitors, and intravenous therapy infusion pumps are becoming smaller and more complex. These devices need to fit into limited space and be portable to move easily between patient rooms and surgical sites, without cumbersome wires and connections.

Solutions for Medical Devices

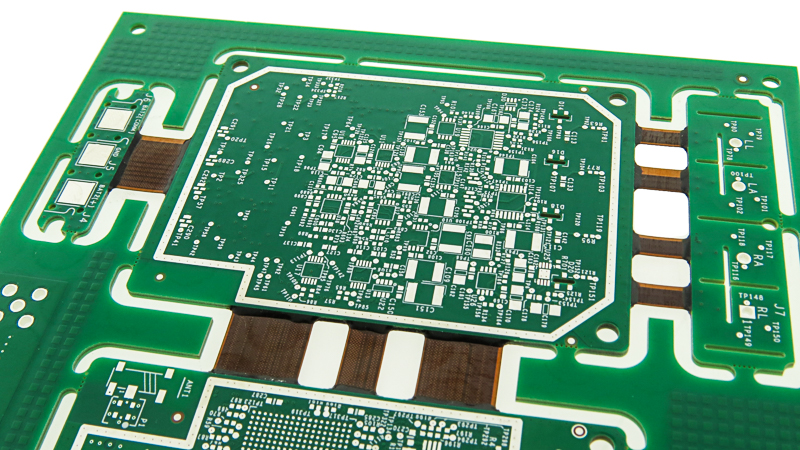

Flexible circuits offer solutions for medical device manufacturers. Epec provides high dielectric constant materials for consistent controls without electrical variances. Flexible circuits eliminate the need for surface-mounted electrical components (SMT), as traces are etched into the flexible and rigid-flex materials. This reduces the size and weight of the circuit board, ensuring the device functions according to specifications. Without cable and wire harnesses and connectors, more components can fit into the device, reducing the risk of moving parts failing or malfunctioning.

Design and Manufacturing Investments

Our design and manufacturing capabilities meet stringent medical standards. Medical devices used directly on or inside patients must be made with acceptable materials that ensure patient safety and care quality. We consider the materials' ability to handle extreme stresses, temperatures, and sterile environments.

Manufacturing Capabilities

We address medical application standards with clean and safe manufacturing environments. Our facilities include clean rooms and advanced equipment like laser drilling and routing, plasma etching, and laser direct imaging. These tools create vias and control drill depth blinds, offering greater lamination adhesion to prevent peeling and separation in the final product.

Medical Applications Using Flexible PCBs

Flexible PCBs are beneficial for various medical applications, including:

- Imaging equipment

- Drug delivery systems

- Pacemakers

- Cochlear implants

- Wireless controllers

- Handheld monitors

- Defibrillators

Medical Device Testing and Certifications

Medical devices require complete documentation and labeling of flex or rigid-flex circuit boards to meet standards and regulations. At Epec, we ensure our parts and manufacturing processes meet ISO and UL certifications. Our PCBs adhere to IPC performance specifications and certifications for quality management. We perform all necessary testing to evaluate reliability and performance, helping your medical applications meet time-to-market deadlines.

By utilizing superior manufacturing equipment, experienced technical workers with 70 years in the industry, and dedicated design engineers, Epec manufactures flex and rigid-flex PCBs that meet the demands of the medical industry.

Customers seeking flexible circuits and rigid-flex PCBs can rely on Epec for circuit boards that meet or exceed mechanical and electronic performance requirements.

Upgrade to the Future of Medical Device Circuitry

Flexible circuits play a huge factor in medical devices. Consult with our Epec engineers today for reliable, compliant, and high-performance rigid-flex PCBs.

Request a Quote Request Design Support Request More Information