Supporting Medical Device Manufacturer with Battery Pack and Charger

Challenge

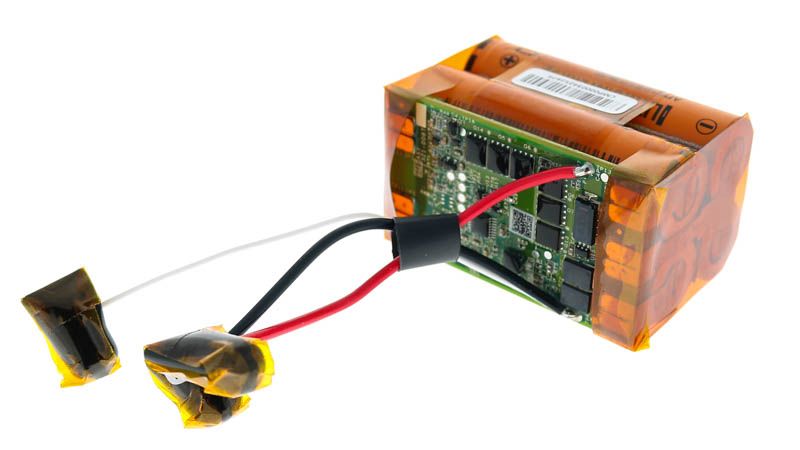

Epec was approached by a leading medical device manufacturer known for its focus on mechanical assemblies, implants, and precision machining. While they maintain an experienced engineering team, their expertise and facilities are centered on mechanical design rather than electrical design or large-scale battery system development.

When it came time to design custom battery packs and chargers for one of their projects, the team quickly realized they lacked the dedicated manufacturing floor, R&D lab, and supply chain access needed to bring their concept into production efficiently. Their engineers were developing solutions from cubicles, without the resources to fully manage the electrical design, sourcing, and validation phases.

They needed a partner with proven battery pack experience, strong supply chain networks, and the ability to collaborate closely throughout the process.

Solution

Epec brought specialized battery design knowledge and a well-established supplier network to support them through every step of development. Our team coordinated weekly check-ins that included project managers, in-house engineers, and contracted engineering support, ensuring seamless communication and alignment.

One of the key contributions was opening access to overseas suppliers, which enabled parallel sourcing of critical components and reduced costs compared to relying only on domestic vendors.

By working side by side with their engineering team, Epec provided the technical and logistical bandwidth that their internal resources could not fully support. This combination of supply chain expertise, design collaboration, and project management allowed them to focus on their core medical device innovations while moving their battery pack and charger project forward.

Result

With Epec’s support, they achieved a more cost-effective and scalable battery pack and charger solution than would have been possible with their in-house team alone. Our partnership reduced long-term component costs and accelerated the development timeline by bridging the gap between their mechanical focus and the electrical expertise required for this new product area.

By leaning on Epec’s design experience and global supplier network, they were able to expand into a new technology space with confidence, without diverting critical internal resources away from their primary mission of advancing medical devices.

Need a Custom Battery Pack for Your Medical Device?

Epec’s engineering team delivers production-ready battery pack solutions tailored to your application. Our expertise ensures a cost-effective design and efficient manufacturing process, without sacrificing performance or reliability. Contact us today to get started.

Request a Quote Request Design Support