Flex & Rigid-Flex Circuit Capabilities

Explore our extensive range of flex and rigid-flex circuit capabilities, featuring cutting-edge materials, substrates, adhesives, solder masks, and coverlay products. Our advanced surface and finishing treatments ensure superior application performance and durability.

Our Flexible PCB Capabilities Include:

Single or Double-Sided Flex Circuits

Our flex PCB designs simplify assembly, reduce interconnect errors, and enhance reliability, all while maintaining cost-efficiency. We offer a variety of configurations, including thru-hole, reverse bare, floating fingers/sculpted circuits, and ZIF terminations.

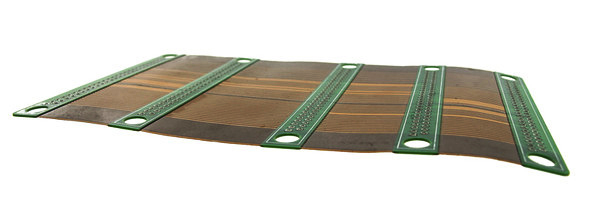

Multilayer Flexible PCBs up to 20 layers

Our high-density multilayer flexible PCBs support multiple conductive layers, including EMI shielding, through-hole assembly, embedded resistors, and controlled impedance. The effective use of ground/shield planes and appropriate connector interfaces ensures optimal high-speed signal integrity. Check out the maximum layers of a flexible PCB before it is no longer flexible.

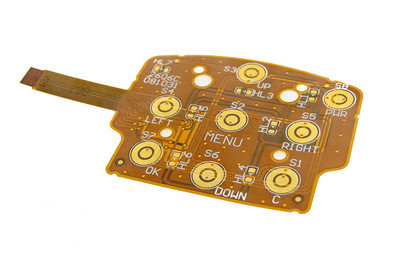

Multilayer Rigid-Flex up to 20+ layers

Our rigid-flex PCB designs offer three-dimensional capabilities, making them ideal for applications with extreme space limitations. These designs enable the processing of multiple board and cable terminations in a single reflow pass, optimizing space and efficiency.

Lines and Spaces

With lines down to 0.0025" and vias down to 50 microns, our designs utilize the smallest component sizes and pitches to enhance electrical performance, signal integrity, and thermal performance, especially when minimizing routing space and via diameters. It is important to be aware of flexible PCB line and space limitations.

Installation of Connectors, Pins, Contacts, SMD, & PTH Component Assembly

We provide comprehensive services including connector, pin, contact, SMD, and plated through-hole component assembly, along with in-circuit testing, conformal coating, and electrostatic protective packaging. Our facilities are IPC 6012/6013 Class I, II, III, and ISO 9001, AS9100 certified. Find the right fit for you with our blog post, Flexible Circuit Boards Connector Options.

Stiffener Supported Areas (using FR-4, Polyimide, etc.)

Stiffeners, attached using thermal bonding or Pressure Sensitive Adhesive (PSA), provide robust support for flexible PCBs. The choice of PSA (e.g., 3M Tape, 3M467, or 3M9077) depends on the reflow cycle requirements and the material to which it will adhere.

Blind & Buried Vias

Our high-density rigid-flex circuits often incorporate blind and buried vias, enabling effective signal routing within high-density components or design areas. Check out this overview of via holes in flexible circuit board designs.

Controlled Impedance

As signal switching speeds, transition times, and clock rates increase, minimizing electrical reflections becomes crucial. Our controlled impedance designs use uniform PCB laminate materials and precise etching processes, ensuring signal transmission stability by eliminating cross-sectional changes in conductors. A closer look at this is available at Flex & Rigid-Flex PCBs: Mastering Controlled Impedance and Signals.

EMI/RF Shielding

We provide effective EMI/RF shielding solutions using copper, silver ink, and shielding films. These protective shields reduce noise and control signal line impedance, meeting stringent electromagnetic and electrostatic interference requirements. Additional details here, Flex PCB EMI Shielding Methods and Materials.

Circuit Size

Our flexible circuits can be designed up to 24" in length or greater, depending on the specific technology and application requirements.

Substrates

We offer a variety of substrates including Polyimide (1-3 mil), Epoxy, and Teflon, tailored to meet the specific needs of your application.

- Polyimide: 1 - 3 mil

- Epoxy

- Teflon

Copper

- Rolled Annealed Copper

- Electro - Deposited

Flex Circuit Adhesives

We provide a range of adhesives such as Modified Acrylic, Modified Epoxy, and Pressure Sensitive Adhesives (PSA), selected to meet your specific application requirements.

Breakdown can be found here, Adhesives in Flexible Circuit Boards: Types and their Uses.

- Modified Acrylic

- Modified Epoxy

- Pressure Sensitive (PSA)

Solder Mask / Coverlay

Our coverlay options offer the same protective functions as traditional solder masks but with added flexibility and durability for flexible circuit boards.

- Polyimide Coverlay: 1/2 mil to 2 mil

- Flexible Liquid Photoimagable (LPI) Soldermask

See our blog post titled what is a flexible circuit coverlay to learn more.

Surface Treatment & Finishes

We offer a range of surface treatments and finishes to enhance the performance and durability of your circuits:

- ENIG (Electroless Nickel - Immersion Gold)

- Immersion Silver

- Hard Gold

- HAL (Non-leaded, RoHS)

- HAL (Leaded)

Stiffeners

Stiffeners reinforce selective areas of flexible circuitry, providing component support, durability, and mounting options. They also serve for strain relief and heat dissipation, using bonding materials like Pressure Sensitive Adhesive (PSA) and Temperature Sensitive Adhesive (TSA). Explore the purpose of a flex circuit stiffener.

Stiffener Materials:

- Unclad FR4 / G10

- Polyimide

Our stiffener materials, including Unclad FR4/G10 and Polyimide, are chosen based on your specific needs. Typical thickness ranges from 0.005" to 0.062".

Maximize Performance with Our Comprehensive Flex and Rigid-Flex Circuit Solutions

From single-sided flex circuits to multi-layer rigid-flex designs, we provide solutions that meet all your needs for electrical performance, miniaturization, and reliability. Our AS9100 and ISO 9001 certifications ensure top-notch quality. Contact us today to discuss your project requirements and discover how we can elevate your designs.

Request a Quote Request Design Support Request More Information