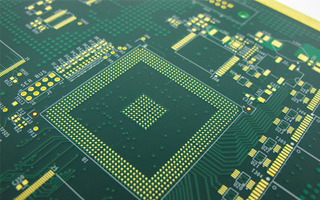

From a complex multi-layer board to a double sided surface mount design, our goal is to provide you a quality product that meets your requirements and is the most cost effective to manufacture. Our experience in IPC Class III standards, very stringent cleanliness requirements, heavy copper, and production tolerances allow us to provide our customers exactly what they need for their end product.

Featured Product Solutions

Delivering Quality PCBs Since 1952

For more than 70 years, Epec has continued its tradition of perfection in engineering and manufacturing printed circuit boards. Our reliability and financial stability has made us an industry leading provider of time-critical, high performance PCB solutions. We support more than 5,000 active customers that represent a wide range of leading original equipment manufacturers (OEM) and electronics manufacturing services (EMS) companies in the automotive, communications, medical, military, aerospace, and portable device industries.

Our custom fabricated printed circuit boards are manufactured to the highest quality. Our engineering team can work with you to review your design to make sure that printed circuit boards can be manufactured with the highest quality at the best overall cost.

See our blog post titled Printed Circuit Boards Are In Our Blood to learn more about the dedication we have to the PCB industry.

NetVia Group - an Epec Company

NetVia Group was founded more than 35 years ago, is a trusted manufacturer of time-sensitive, high-technology printed circuit boards for OEMs in the most demanding industries, with a manufacturing facility in Irving, Texas.

Why 70 Years of PCB Manufacturing Experience Matters

Truly understanding the newest technologies in PCB design and manufacturing ensures that our customers will get what they want, when they want it, and without delay. Whether it is rapid delivery, reliable and stable production of the highest technology PCBs, or a competitive price, we can help you reach your goals.

Every PCB design choice will affect your pricing and delivery, so our objective is always to determine what the customers’ priorities are and then create a solution around those priorities. By offering things like free DFM (Design for Manufacturing) PCB file reviews, 24/7 engineering support, Electrolytic Hard Gold/Soft Gold/ENIG finishes, MIL-PRF/AS9100 Certification, and many others, Epec Engineered Technologies has the experience to meet your needs.

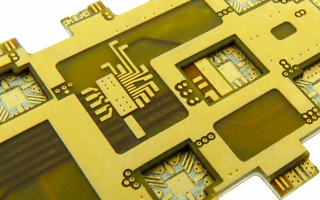

Advanced HDI, Stacked Microvias, Multilayer Advanced RF/Microwave, laser drilled microvias, cavity boards, heavy/extreme copper, via-in-pad, DOD/ITAR, and more our within our standard capabilities allows us to quickly get our customers the highest technology printed circuit boards.

Watch Our Recent Webinar

PCB Design: Top Factors Related to Data Routing and Layout

Quote & Order Your PCBs Online with InstantPCBQuote

InstantPCBQuote, our online quote and ordering tool for both rigid PCBs and flexible circuits offers higher technology options available online. From a 16-layer controlled impedance design with 4 oz outer copper weight, or blind and buried vias, we got you covered.

Our online quote and ordering tool allows you to you get the high-tech PCB you need for both prototype and production quantities.

Start Quoting Your PCBs Online