PCB Peelable Solder Masks

Often printed circuit boards require protection of selected board areas during the surface finish or assembly process to keep solder from flowing onto contacts, terminals and plated through holes (PTH). In the past hear resistant tape was applied manually in various shapes and sizes causing delays to production, over time cost and more time and cost to remove the tape.

Peelable solder masks, provide printed circuit boards with protection in soldering processes like wave soldering, reflow soldering or at the PCB level a surface finish protection. Multi-surface finishes such as carbon ink, hard gold or a bondable gold need protection from the balance of the surface finishing being applied such as ENIG or Immersion Silver. Peelable mask is a reliable, time-saving and cost-saving process, this application has long surpassed manual masking with heat-resistant tapes such as Kapton.

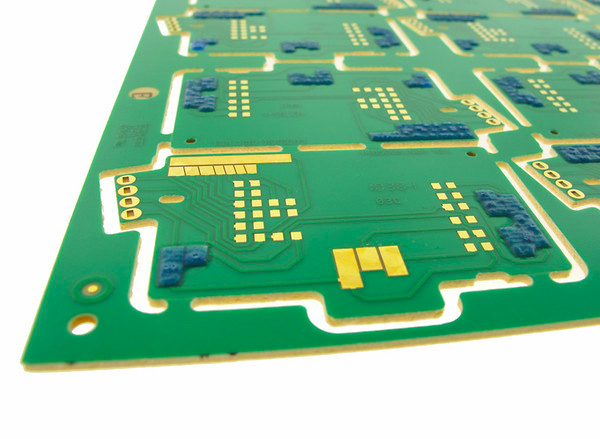

Printed Circuit Board with Peelable Solder Mask

Peelable Solder Masks (also known as removable, strippable mask or blue-mask) are applied by screen-printing, act as in-process protection and are removed after processing at the contracted assembly house. The printed circuit board fabricator can apply the mask in any design or shape on one or several sections per side at a time. The PCB supplier can create one fluid piece which will allow the customer to peel the entire design off in one pull.

General Features and Advantages of the Peelable Solder Mask

- Time and cost-saving process compared to taping.

- Taping is a non-mechanical process that involves people. Depending on the quantity involved, it could take several people several hours or days to complete the taping process. The tape is impossible to modify to mask the needed areas often added more cost in labor.

- Protection of complex structures and shapes by efficient screen-printing.

- Many areas on the PCB may need protection from the assembly process and on different surface areas of the part that are different shapes. Using a Gerber file creating a layer to be protected allows for a single operation to make a screen and allowing the mask to be applied in one sweep, protecting all areas easily.

There are several steps to assembly - larger features can be covered, and holes up to 0.120 diameter are easily managed. This mask protective layer prevents splash through to sensitive features nearby that require no-assembly. Removal of the mask at a later time in process allows you to hand assemble or process mechanically the balance of the part.

- The peelable mask is easily removed by lifting at a section of the mask off the surface and pulling slowly away from the lifted part. The mask leaves behind no residue or particles and requires no additional cleaning. Unlike the old tape application, often alcohol was used to remove any remaining tack from the tape.

- Non-contaminating, non-staining, and non-corrosive are three critical component essential to the success of the PCB assembly process.

- RoHS compliant, this mask can be used all surface finishes and remains fully compliant and certified. It is stable to 550°F (288°C), phthalate-free, has low toxicity, and is environmentally safe.

It is compatible with rosin, no-clean, and water-soluble flux types for ease of manufacturing at the assembly level. This underutilized process should be reviewed for its pliable protection of critical areas on your PCBs.

Need a PCB with Peelable Solder Mask?

Switch to peelable solder masks and slash your PCB assembly time and costs. Get RoHS-compliant, zero-residue protection.

Request a Quote Request Design Support Request More Information