High Quality SMT Stencils

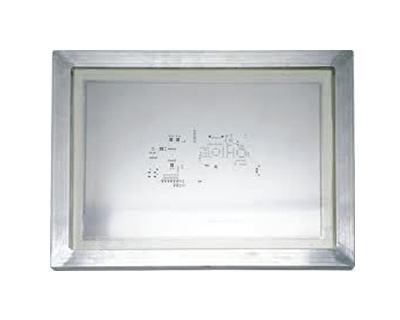

Framed SMT Stencils

Framed SMT stencils or "glue-in" stencils are laser-cut solder paste stencils permanently mounted in a stencil frame using a mesh border to tightly stretch the stencil foil taut in the frame. Framed stencils are designed for high volume screen printing on printed circuit boards. Framed SMT stencils have smooth aperture walls and can be used for 16 Mil pitch and below and for Micro BGA's.

Framed SMT Stencil Features:

- Unique Process for smooth aperture walls

- Very clean laser-cut apertures

- Excellent print performance

- Excellent for high-volume stencil printing on printed circuit boards

- Unique process creates permanent non-removable non-fading fiducial

- All framed SMT stencils are double bonded to extreme wear

- 24-hour turnaround standard

| Framed SMT Stencil Specs: | |

|---|---|

| Technology | 100% laser cut |

| Material Used | Stainless Steel |

| Frame Types | Cast, Space Saver |

| Stencil Thickness | .002 - .016 inches |

| Minimum Cut Width | .002 inches |

| Maximum Size | 29"x29" inches |

| Aperture Tolerance | within .00025 inches |

| Allow for Fiducial Data | Yes |

| Allow for Panelized Data | Yes |

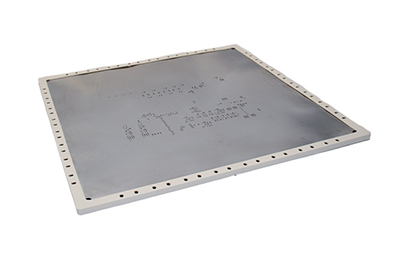

Frameless SMT Stencils

Frameless SMT Stencils also referred to as foils are laser cut solder paste stencils designed to work with stencil tensioning systems known as reusable stencil frames. This type of stencil does not need to be permanently glued in a frame. Frameless stencils are significantly less expensive than framed stencils and provide money-saving storage while still delivering superior quality and performance.

Frameless SMT Stencil Features:

- Reduced storage space requirements

- Significantly less expensive than framed stencils

- Excellent for prototype printed circuit board assembly or short runs

- Smooth aperture walls, can be used for 16 Mil pitch and below and for Micro BGA's

- 24-hour turnaround standard

| Frameless SMT Stencil Specs: | |

|---|---|

| Technology | 100% laser cut |

| Material Used | Stainless Steel |

| Stencil Thickness | .002 - .016 inches |

| Minimum Cut Width | .002 inches |

| Maximum Size | 29"x29" inches |

| Allow for Fiducial Data | Yes |

| Allow for Panelized Data | Yes |

Prototype SMT Stencils

Prototype SMT stencils are laser cut stencils custom-made from your Gerber or CAD files to match your prototype printed circuit board. These frameless solder paste stencils are specifically designed for manual printing.

Prototype SMT Stencil Features:

- Eliminate the tedious error-prone process of hand soldering your prototype circuit boards

- Reduce PCB prototype assembly time

- Improve quality of your prototype printed circuit boards

- Lower cost than production stencil

- Includes complete "how-to" instructions

- 24-hour turnaround standard

| Prototype SMT Stencil Specs: | |

|---|---|

| Technology | 100% laser cut |

| Material Used | Stainless Steel |

| Stencil Thickness | .002 - .016 inches |

| Minimum Cut Width | .002 inches |

| Maximum Size | 12"x10" inches |

| Aperture Tolerance | within .00025 inches |

| Allow for Fiducial Data | Yes |

Electroformed SMT Stencils

Electroformed SMT stencils are nickel-based, electroform foils permanently mounted in a stencil frame using a mesh border to tightly stretch the stencil foil taut in the frame. Electroformed stencils offer the best paste release characteristics available and are frequently used for fine pitch (20 mil to 12 mil pitch) SMT applications on printed circuit boards. They are also used for µBGA's, Flip Chip, and Wafer Bumping (12 mil to 6 mil pitch).

Electroformed SMT Stencil Features:

- The smooth trapezoidal sidewalls of an electroformed stencil allow for better paste release

- Nickel has a lower coefficient of friction compared to stainless steel

- Electroform foils are harder than full hard stainless steel of comparable thickness, providing for longer stencil life

- 24-hour turnaround standard

| Electroformed SMT Stencil Specs: | |

|---|---|

| Technology | Electroforming |

| Material Used | Nickel |

| Suitable Applications | All Component Pitches |

| Aperture Tolerance | ± 0.0003" |

| Stencil Thickness | 0.001” - 0.006” All thicknesses are available at increments of 0.0001” increments. |

| Positional Accuracy | ± 0.0003" |