RoHS Compliant Circuit Boards

Our Commitment to Environmental Responsibility

Epec is a leader in Printed Circuit Board solutions and is committed to taking an active role in working closely with our customers and suppliers to identify and rapidly eliminate hazardous substances from their products. As an ISO 9001:2015 registered company, Epec is fully supportive of electronics industry efforts throughout the world to phase out the use of lead and other undesirable elements.

Lead Free & RoHS Compliant Initiative

Epec is a leader in providing an extensive array of lead free printed circuit board solutions. Epec's lead free products are fully RoHS compliant.

RoHS Restricted Materials

| Banned Substance | RoHS LIMIT: MCV* PPM |

|---|---|

| Lead (Pb) | 1000 |

| Mercury (Hg) | 1000 |

| Cadmium (Cd) | 100 |

| Hexavalent Chromium (Cr+6) | 1000 |

| Polybrominated Biphenyl (PBB) | 1000 |

| Polybrominated Diphenyl Ether (PBDE) | 1000 |

| Bis(2-ethylhexyl) Phthalate (DEHP) | 1000 |

| Butyl Benzyl Phthalate (BBP) | 1000 |

| Dibutyl Phthalate (DBP) | 1000 |

| Diisobutyl Phthalate (DIBP) | 1000 |

* MCV - Maximum concentration values allowed in homogeneous materials

Halogen Free Materials

What are Halogen-free requirements?

- Bromine must be below 900 PPM by weight

- Chlorine must be below 900 PPM by weight

- Combined Bromine + Chlorine must be below 1200 PPM by weight

Laminate

- The TBPPA based fire retardant material must be replaced

- We do offer Halogen-free materials

Soldermask

- Most soldermasks contain chlorine

- We do have a limited offering of halogen-free masks

RoHS Compliant Material Identification and Packaging

Epec provides a RoHS Certification of Conformance (C of C) with all shipments. To allow easy identification of all RoHS compliant products and materials, all our packaging has a RoHS/Pb-Free label.

IPC-1752 RoHS Materials Declaration Standard

Compliance requires that Epec and our suppliers understand the material composition of our products—from FR4 laminate, solder mask, silkscreen, and plating, to surface finish and finished boards. We will provide you with technical documentation and supplier declarations to support your "due diligence." You are expected to provide this documentation upon request of EU regulators.

RoHS Compliant Surface Finish Options

Epec has qualified a wide variety of RoHS compliant surface finish alternatives.

These qualified finishes include:

| Surface Finishes | Shelf Life | Coplanarity | Multiple Rework |

|---|---|---|---|

| ENIG | 12+ Months | Yes | Yes |

| Immersion Silver | *6-9 Months | Yes | Limited |

| Lead Free HASL | 12 Months | Moderate | Yes |

| OSP | 6-12 Months | Yes | No |

| Immersion Tin | 3 Months | Yes | Limited |

*With proper packaging and storage conditions

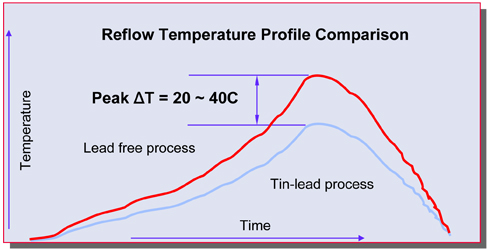

Higher Lead-free Assembly Temperature

- Low thermal mass assembly reflow @ 240 –245C

- Higher thermal mass assembly reflow @ 260C

- Lead-free PCB temperature is 30C higher than SnPb process

- Up to 6 soldering/rework cycles may be required

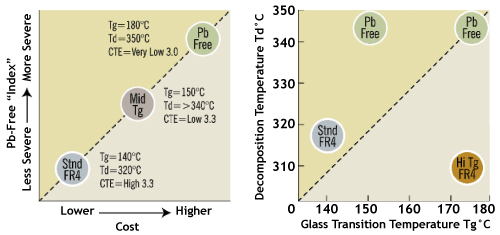

Pb-Free Compatible FR4 Materials

Lead Free Process Compatible Material Solutions

The assembly of lead free products requires the use of material that will not break down at higher processing temperatures. To better facilitate the industry transition to lead free PCBs, Epec offers the following broad assortment of standard, off-the-shelf, lead free FR4 substrates:

RoHS Capable Substrate Materials

| Product | Resin Matrix | Td, °C | Tg, °C | T-288 Minutes | CTE Z-Axis | Dk @ 2GHz | Df @ 2GHz |

|---|---|---|---|---|---|---|---|

| Standard Electrical Performance | |||||||

| Isola IS410 | Phenolic epoxy | 350 | 180 | >15 | 3.50% | 4.2-4.7 | .018-.021 |

| Iteq IT-180TC | Phenolic epoxy | 385 | 180 | >10 | 3.00% | 4.2-4.7 | .018-.021 |

| Polyclad 370HR | Phenolic epoxy | 350 | 180 | pass | 2.70% | 4.4-4.7 | .018-.021 |

| High Electrical Performance (Low Loss) | |||||||

| Isola FR415 | Non-phenolic/non-dicey | 370 | 190 | >20 | 2.90% | 3.80-3.90 | .016-.017 |

| Isola FR408 | Modified epoxy | 360 | 180 | >15 | 3.50% | 3.55-3.6 | .011-.0125 |

| Polyclad Getek | Polyphenylene oxide | 345 | 175 | pass | 3.80% | 3.5-3.7 | .009-.011 |

| High Electrical Performance (Ultra Low Loss) | |||||||

| Rogers RO4350 | Hydrocarbon ceramic | 395 | 300 | >180 | <3.0 | 3.48 | 0.004 |

| Isola IS620 | Low Dk/Df | 353 | 215 | >15 | 2.80% | 3.55-3.6 | 0.008 |

| Polyclad 621 | Polyphenylene ether | 400 | 210 | pass | 3.00% | 3.3-3.55 | .0045-.007 |

| Nelco-13SI | Enhanced epoxy | 365 | 210 | pass | 3.50% | 3.3-3.4 | .007-.008 |

*With proper packaging and storage conditions. The principle performance criteria for lead free processing capability is Td (decomposition temperature) >340°C.

For additional information visit Epec's PCB RoHS FAQ page or see blog post titled RoHS and Circuit Board Laminates - Not Just Tg Anymore for more information.

Go Green Without Compromising Quality

Choose Epec's RoHS Compliant PCBs. Validate your commitment to environmental responsibility now!

Request a Quote Request Design Support Request More Information