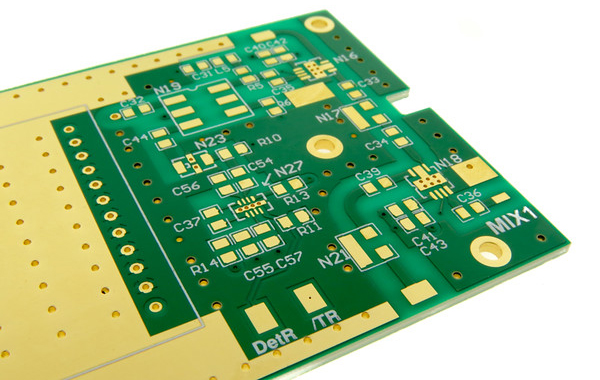

Microwave & RF Printed Circuit Boards

In order to meet increasing demands for Microwave & RF Printed Circuit Boards for our customers all around the world, we have increased our investment over the last few years so that we have become a world-class manufacturer of PCBs using high frequency laminates.

The definition of RF and microwave PCBs is that they contain components that carry RF or microwave signals. These signals vary in frequency from, 50MHz to above 2 GHz, and these frequencies define the differences in components between RF and microwave PCBs and other PCB types.

These applications typically require laminates with specialized electrical, thermal, mechanical, or other performance characteristics that exceed those of traditional standard FR-4 materials. With our many years of experience with PTFE-based microwave laminate, we understand the high reliability and tight tolerance requirements of most applications.

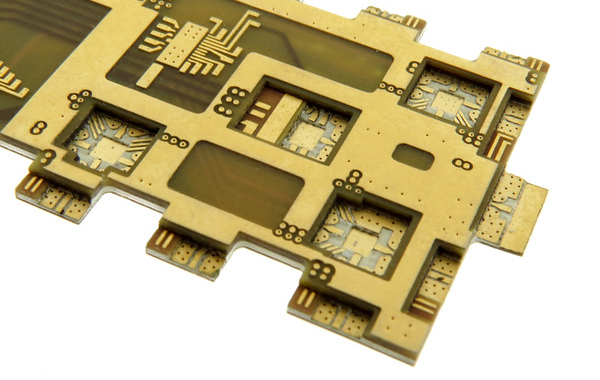

There is a specific grouping RF & microwave PCBs that incorporate both FR-4 and PTFE or other materials together in the same stack up that are called Hybrid PCBs. You can get more information on these hybrid designs and our unique capabilities around these high technology PCBs.

Our experience allows us to provide our customers with the most comprehensive service in circuit board production for these products as we have invested in.

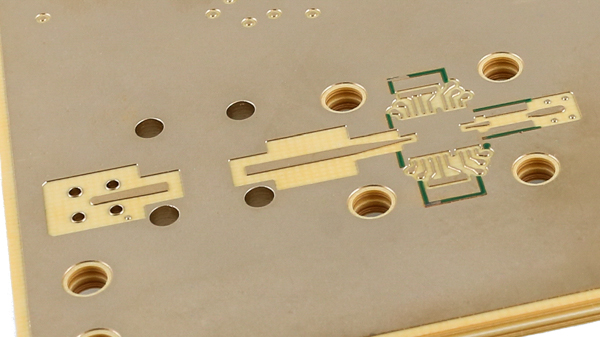

Along with being the industry leaders in PCB manufacturing, we also own a high-precision CNC machining company named Metal Craft Machining. This not only allows us to be able to machine to very high tolerances on PCB features in-house using our 3-, 4-, and 5-axis CNC equipment, it also allows us to machine aluminum and other metals to bond to the PCBs, which are often a key part of RF & Microwave PCBs. Most PCB fabricators have to outsource this critical function and are at the mercy of a third-party vendor for quality and delivery. Here at Epec Engineered Technologies, we have invested heavily in our equipment set to give us the most flexibility and control over most of our needed processes.

PCB Material Stock

Will all the different features of every RF PCB application, we have developed partnerships with the key material suppliers such as Rogers, Arlon, Nelco, and Taconic just to name a few. While many of the materials are very specialized, we do hold significant stock of product in our warehouse from Rogers (4003 & 4350 series) and Arlon. Not many companies are prepared to do that given the high cost of carrying inventory to be able to respond quickly.

High technology circuit boards fabricated with high frequency laminates can be difficult to design because of the sensitivity of the signals and the challenges with managing the thermal heat transfer in your application. The best high-frequency PCB materials have low thermal conductivity versus the standard FR-4 material used in standard PCBs.

RF and microwave signals are very sensitive to noise and have much tighter impedance tolerances than traditional digital circuit boards. By utilizing ground plans and using a generous bend radius on impedance controlled traces can help make the design perform in the most efficient manner.

Because wavelength of a circuit is frequency dependent and material dependent, PCB materials with higher dielectric constant (Dk) values can result in smaller PCBs as miniaturize circuit designs can be used for specific impedance and frequency ranges. Oftentimes high-Dk laminates (Dk of 6 or higher) are combined with lower cost FR-4 materials to create hybrid multilayer designs.

Understanding the coefficient of thermal expansion (CTE), dielectric constant, thermal coefficient, temperature coefficient of dielectric constant (TCDk), dissipation factor (Df), and even items like relative permittivity, and loss tangent of the PCB materials available will help the RF PCB designer create a robust design that will exceed the required expectations.

Some of the different material RF PCB material types that we work with are:

Ceramic-filled PTFE composites, which have exceptional electrical and mechanical stability. Rogers RO3000 series circuit materials have consistent mechanical properties, regardless of the dielectric constant (Dk) selected, which allows multi-layer board designs that use different dielectric constant materials without encountering war-page or reliability problems. The Taconic RF series of products has a low dissipation factor with high thermal conductivity possible so it will not oxidize, yellow, or show upward drift in dielectric constant and dissipation factor like its hydrocarbon-based competitors.

Ultra-low Loss, Highly Heat-Resistant, Halogen Free Megtron 6 circuit board material. With high glass transition temperature (Tg) and the low expansion ratio of hydrocarbon resin-based MEGTRON 6 - makes it ideal for High-Density Interconnect (HDI) and high speed (above 3 GHz) constructions.

Woven Glass Reinforced PTFE laminates are manufactured with very lightweight woven fiberglass and are more dimensionally stable than chopped fiber reinforced PTFE composites. Materials such as the Taconic TL family of products have a low dissipation factor, and this is perfect for radar applications designed at 77 GHz as well as other antennas in millimeter-wave frequencies.

Hydrocarbon ceramic laminates are used in microwave and millimeter-wave frequency designs as this low loss material offers easier use in circuit fabrication and streamlined properties over traditional PTFE materials. Rogers RO4000 series of products come in a wide range of DK values (2.55-6.15) and have above average thermal conductivity (.6-.8).

Filled PTFE (random glass or ceramic) composite laminates such as the Rogers RT/duroid® high frequency circuit materials have low electrical loss, low moisture absorption, and low outgassing properties that are preferred in space applications.

Thermoset microwave laminates combine low thermal coefficient of dielectric constant (Dk), a copper matched coefficient of thermal expansion and excellent mechanical reliability. Rogers TMM materials are high-frequency laminates ideal for high-reliability strip-line and micro-strip applications.

Competitive Matrix

| Resin System | Category | Dk @ 10 GHZ | Df @ 10 GHz | Competitors | Product Name | Dk | Df |

|---|---|---|---|---|---|---|---|

| I-Speed | Low Dk/Df | 3.64 | 0.0094 | Panasonic | Megtron 4 | 3.80 | 0.0050 |

| TUC | Thunderclad | 3.90 | 0.0095 | ||||

| AGC/NELCO | N4800-20 | 3.80 | 0.0075 | ||||

| AGC/NELCO | Meteorwave 1000 | 3.70 | 0.0055 | ||||

| Doosan | DS-7409D (X) | 3.80 | 0.0050 | ||||

| I-TeraMT40 | Very Low Dk/Df | 3.30 | 0.0036 | Panasonic | Megtron 6 | 3.61 | 0.0040 |

| AGC/Neclo | Meteorwave 2000 | 3.40 | 0.0040 | ||||

| AGC/Neclo | Meteorwave 3000 | 3.80 | 0.0048 | ||||

| Rogers | RO4350B | 3.48 | 0.0037 | ||||

| TUC | TU-993 | 3.40 | 0.0025 | ||||

| Doosan | DS-7409D (V) | 3.65 | 0.0015 | ||||

| I-TeraMT40 RF | RF | 3.45 | 0.0031 | Rogers | RO4350B | 3.48 | 0.0037 |

| Arlon | AD350 | 3.50 | 0.0030 | ||||

| Taconic | RF35 | 3.50 | 0.0025 | ||||

| AGC/Neclo | NH9350 | 3.50 | 0.0030 | ||||

| Tachyon-100G | Ultra Low Dk/Df | 3.00 | 0.0021 | Panasonic | Megtron 7N | 3.35 | 0.0020 |

| AGC/Neclo | Meteorwave 4000 | 3.50 | 0.0040 | ||||

| EMC | EM-891K | 3.10 | 0.0033 | ||||

| Doosan | DS-7409DV(N) | 3.35 | 0.0010 | ||||

| AstraMT77 | RF | 3.00 | 0.0017 | Rogers | RO3003 | 3.0 | 0.0013 |

| Arlon | AD300C | 3.0 | 0.0020 | ||||

| AGC/Neclo | NX9300 | 3.0 | 0.0023 |

There are many more materials available, which we have experience with so if you don’t see what you are looking for listed, send us a request for more information and we can help you design an RF or high-speed PCB to meet your requirement.

Specialized Processing Equipment

Much of the processing for Microwave/RF PCBs can be done on standard fabrication equipment. However, the need for specialized equipment is requires for the most demanding designs. We have invested significantly so that we have in-house: Plasma Etch equipment to ensure that the quality of the thru holes is at the highest level. Plasma etching uses plasmas or etchant gases for the removal of substrate materials in the through holes and to prepare the surface for coating. Laser Direct Imaging (LDI) equipment versus the more traditional photo exposure tools so that we can hold very tight trace widths and front-to-back registration requirements. Laser drilling equipment, which is needed for many of the different materials as mechanical cutting will leave burrs, loosen fabric, or can discolor due to heat. This also allows us to consistently provide microvias to our customers of the highest quality.

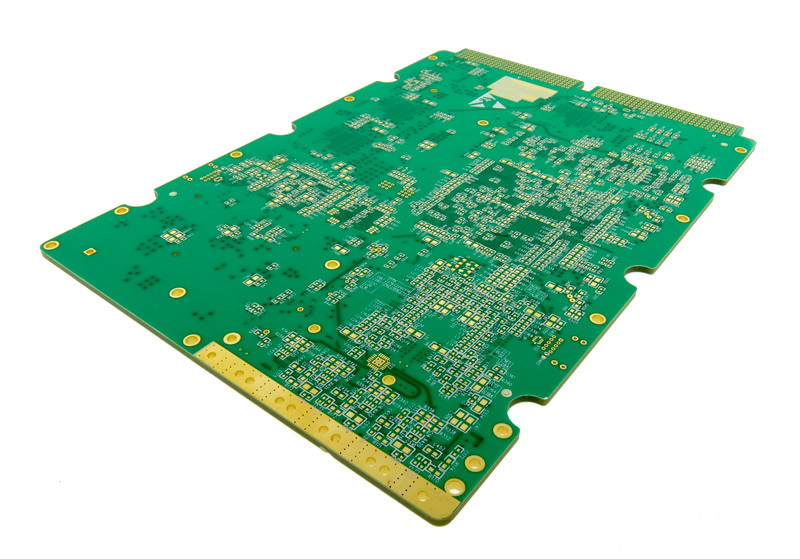

Wide Ranging Capabilities

In addition to standard Microwave/RF PCBs our capabilities using PTFE laminates also include:

- Hybrid or Mixed Dielectric Boards (PTFE/FR-4 combinations)

- Metal Backed and Metal Core PCBs

- Cavity Boards (Mechanical and Laser Drilled)

- Edge Plating

- Constellations

- Large Format PCBs

- Front to back registration of etched cores to +/-.002″

- +/- 0.001″ tolerance on etched features for un-plated 1oz copper

- Blind/Buried, Via-in-Pad, Micro Vias, Stacked Vias, and Laser Via's

- Soft Gold and ENEPIG Plating

- Sequential lamination

Selective solder mask on a RF circuit boards design.

Our Application Experience

Our experience includes applications in wireless base stations, aerospace and defense, automotive, high-speed digital, advanced chip packaging, ATE, and many other industries.

Elevate Your RF & Microwave PCB Performance

Partner with Epec Engineered Technologies for comprehensive in-house solutions, high-precision manufacturing, and rapid response inventory of laminate materials.

Request a Quote Request Design Support Request More Information