Types of Coaxial Cables

Since the advent of the RG numbering system, manufacturers have continually advanced cable technology through research and development. This has been necessary to keep pace with emerging applications and includes improvements to both materials and manufacturing processes. An array of coax with expanded operational capabilities has emerged, allowing additional system design capabilities. More information available here, Coaxial Cable and Connector Options for Low-Cost RF Cables.

Coax Type and Electrical Specifications

| Coax Description | Outside Diameter (in) | Dielectric Material | Center Conductor Material | Shield Material | dB/100 ft | |

|---|---|---|---|---|---|---|

| @400 MHz | @10 GHz | |||||

| RG-58C | 0.195 | PE | Ag/Cu | Ag/Cu Braid | 14 | |

| RG-119 | 0.465 | ST | Ag/Cu | Ag/Cu Braid | 3.8 | |

| RG-120 | 0.523 | ST | Ag/Cu | Ag/Cu Braid | 3.8 | |

| RG-122 | 0.16 | PE | Ag/Cu | Ag/Cu Braid | 18 | |

| RG-142/A/B | 0.195 | ST | Ag/Cu | Ag/Cu Braid | 9 | |

| RG-177 | 0.895 | PE | Ag/Cu | Ag/Cu Braid | 2.8 | |

| RG-178/A/B | 0.072 | PTFE | Ag/Cu | Ag/Cu Braid | 29 | |

| RG-211/A | 0.73 | ST | Ag/Cu | Ag/Cu Braid | 2.3 | |

| RG-212 | 0.332 | PE | Ag/Cu | Ag/Cu Braid | 6.5 | |

| RG-213 | 0.405 | PE | Ag/Cu | Ag/Cu Braid | 5.5 | |

| RG-214 | 0.425 | PE | Ag/Cu | Ag/Cu Double Braid | 5.5 | |

| RG-215 | 0.463 | PE | Ag/Cu | Ag/Cu Braid | 5.5 | |

| RG-217 | 0.545 | PE | Ag/Cu | Ag/Cu Braid | 4.3 | |

| RG-218 | 0.87 | PE | Ag/Cu | Ag/Cu Braid | 2.5 | |

| RG-219 | 0.928 | PE | Ag/Cu | Ag/Cu Braid | 2.5 | |

| RG-223 | 0.211 | PE | Ag/Cu | Ag/Cu Double Braid | 8.8 | |

| RG-303 | 0.17 | PTFE | Ag/Cu | Ag/Cu Braid | 9 | |

| RG-304 | 0.28 | PTFE | Ag/Cu | Ag/Cu Braid | 6 | |

| RG-316 | 0.102 | PTFE | Ag/Cu | Ag/Cu Braid | 20 | |

| RG-393 | 0.39 | PTFE | Ag/Cu | Ag/Cu Braid | 5 | |

| RG-400 | 0.195 | PTFE | Ag/Cu | Ag/Cu Braid | 9.6 | |

| RG-401 Semi-Rigid | 0.25 | PTFE | Ag/Cu | Cu Solid Jacket | 33 | |

| RG-402 Formable | 0.141 | PTFE | Ag/Cu | Sn/Cu Braid | 50 | |

| RG-402 Semi-Rigid | 0.141 | PTFE | Ag/Cu | Cu Solid Jacket | 41 | |

| RG-403 | 0.116 | PTFE | Ag/Cu/ | Ag/Cu Braid | 29 | |

| RG-405 Formable | 0.086 | PTFE | Ag/Cu | Sn/Cu Braid | 82 | |

| RG-405 Semi-Rigid | 0.086 | PTFE | Ag/Cu | Cu Solid Jacket | 65 | |

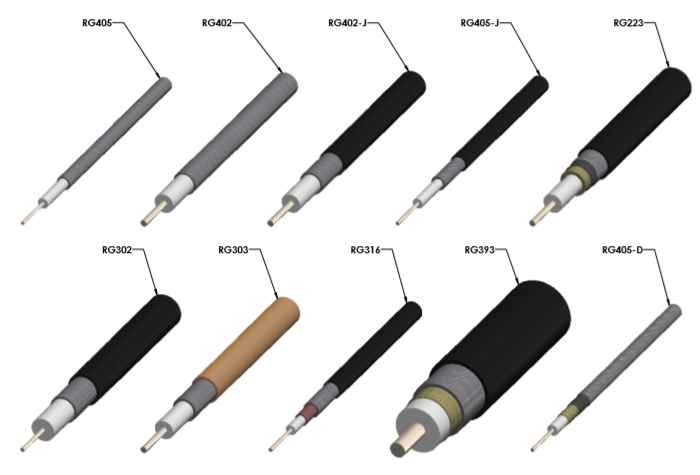

Diagram of Coaxial Cables Types

Flexible Coax

Having originally set the standard of performance, flex has been the go-to for military and aerospace applications. This type of coax yields lower electrical performance when compared to semi-rigid and formable cables but offers lower cost. A flex cable utilizes either a stranded center conductor where repeated flexing is required or a solid conductor when lower loss is necessary.

Generally, a silver-plated copper shielding braid over the insulator provides a high level of flexibility but shielding is not continuous due to the air gaps between the stranded braid. The shielding can be further degraded when flexing of the assembly occurs, increasing the size of the air gaps. This can be overcome by specifying a second or third layer of shielding, but flexibility is then sacrificed.

Semi-Rigid Coax

Utilizing a solid outer shield made of either copper or aluminum, the semi-rigid cable provides superior shielding compared to a woven braid. This is especially apparent when higher operational frequencies are required. While offering higher shielding performance, this coax is also less flexible and therefore requires fixturing to achieve complex routing bends.

Formable Coax

Constructed with a tin-filled copper outer conductor braid, the formable cable has similar performance characteristics of semi-rigid but offers the flexibility to be formed and reformed without degradation to the coax. Being hand formable, a cost savings is realized due to a lack of need for fixturing where routing bends are required.