Cable Assemblies Manufacturing Process

Below you will find our image gallery from the cable assemblies manufacturing process. Including quality assurance, signal integrity analysis, environmental analysis, and custom designs.

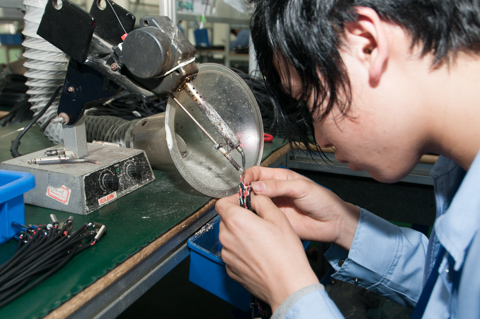

Manual Termination – Soldering

To accommodate short run manufacturing, manual termination is utilized to meet customer demands from both a quantity and lead time perspective.

Over Molding – Multi-Cavity Capabilities

Our design engineers look at the customer's needs and design mold tooling to process as many terminations as possible. This efficient use of machine capacity reduces costs and increases throughput.

Ultra Sonic Plastic Welding

The process of taking two plastics and forming them together by ultra sonic plastic welding.

Quality Assurance – Signal Integrity Analysis

Each completed assembly is electrically tested for faults. This testing includes but is not limited to opens, shorts, shield integrity, and correct pin-outs.

Quality Assurance – Insertion Loss Analysis

Insertion loss is analyzed on higher speed assemblies. This analysis checks all frequencies of interest and detects any spikes or suck-outs.

Custom Color Matching Capabilities

Capabilities include the ability to meet customer's requests for color matching of over molded products. Through the use of equipment that measures color by wavelength, we can match and custom color.

Quality Assurance – Physical Analysis

Our products are physically tested to ensure they meet the rigorous demands our customer's expect of our assemblies. Reliability is crucial and our products meet or exceed the physical demands needed by our customer's.

Quality Assurance – Environmental Analysis

Our line of products includes those meant for harsh environments. We fully test our products to make sure they will withstand the day to day abuse they will be exposed to in their expected service life.

Over Molding – Custom Color Compounding

Our capabilities allow us to match our over mold compounds to almost any color desired by the customer. This process provides the customer with an assembly that can match their equipment color or to provide an assembly that is color coded to a specific application, if it is needed.

Over Molding – Custom Designs

Our design engineers and tooling shop are capable of creating molds that include customer names, product names, logos, or any artwork required by the customer.

Custom Wire Harnesses

Custom wire harnesses fall well within our expertise. Any length, any number of conductors, and any number of terminations are within our capability.

Semi-Automated Termination

To help keep costs under control, automation is utilized to the fullest extent possible.

Connector Termination

By working with all of the major connector manufacturers, we've been able to install the latest state of the art termination equipment. We've also been able to integrate this equipment into our short run capabilities to enable us to offer the highest quality terminations at the lowest possible cost.

IDC Termination/Custom Jumper Cables

Whether your needs are for a PVC or a plenum ribbon cable, 2 conductors or 100, 0.025” spacing or 0.156” spacing, or any custom ribbon cable, our factories have the experience and expertise to terminate them properly.

Supply Chain Management/In-House Inventory

From managing supply chains to shipping products when they are needed, our capabilities work to make the customer's operations problem free. We will work with our customers to build and ship assemblies when they are needed, in the quantity that is needed.

Need Help Manufacturing a Custom Cable Assembly?

Dive into the intricacies of our cable assembly manufacturing. From quality assurance to custom designs, get a comprehensive understanding.

Request a Quote Request Design Support Request More Information