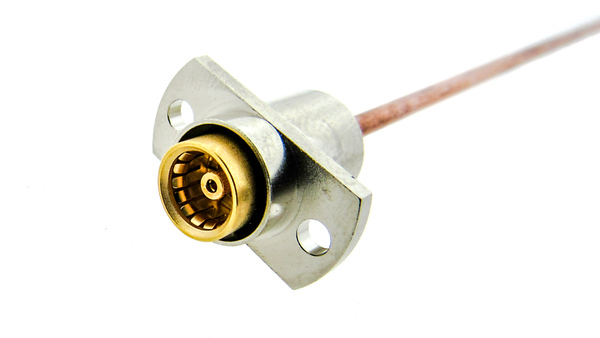

Coaxial Cable Assemblies

Epec Engineered Technologies is an ISO9001: 2015 certified manufacturing company that provides cost-effective products with the world class quality.

We conduct all product design, assembly, and test activity within a 52,000-square-foot, state-of-the-art facility in New Bedford, MA that is equipped with the latest in design software, test instrumentation, prototype and manufacturing equipment.

Our New Bedford, MA Facility Utilizes.

- Lean Manufacturing and Assembly Lines

- Wide Variety of Products

- IPC Standards

- Specialized RF Capabilities

Connector Configurations

- Identical Connector Types

- Dissimilar Connector Types

- Dissimilar Connector Gender

- Coax Shield / Contact to Connector Direct Solder / Solder Attachment

- Coax Shield / Contact to Connector Crimp / Solder Attachment

Coax Size Capability

- 0.020”

- 0.031”

- 0.047”

- 0.070”

- 0.086”

- 0.120”

- 0.141”

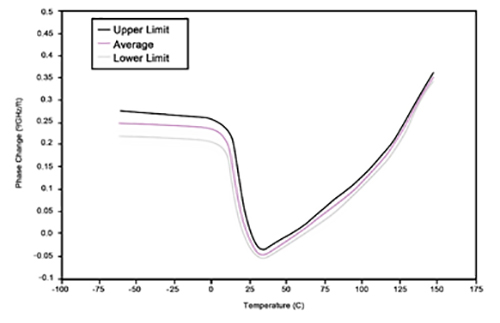

Phase Matching

This is defined as coax cable assemblies that require the same electrical length, specified in degrees at a determined frequency. The tolerance of this match is heavily dependent on absolute coax length, operational temperatures, connector quality and assembly techniques.

Our Capabilities Include:

- Assemblies can be matched to an established standard or to other cables in a set.

- Phase matched cables can be provided with tolerances of a +/-3 degrees, application and materials dependent.

- Thermal stress relief cycling is required to achieve consistent matching.

- Agilent ENA Network Analyzer is used for the measurement of electrical length.

Build Standard and Mil-Spec

- IPC-A-610 Class 3: Specification of quality acceptability requirements for electronic assemblies.

- MIL-C-17: A government specification document used to standardize coaxial cables.

- MIL-DTL-87104: Specification covering the general requirements and tests for coaxial assemblies for use with airborne electronic systems.

- MIL-C-39012: Specification controls of RF cable connector performance.

- MIL-STD-202: Thermal shock.