SMART Human-Machine Interfaces

Several new technologies are changing how companies think, design, and integrate user interface controls into their devices. These new technologies along with the continued push towards all devices being connected using internet of things (IoT) technologies will take operational efficiency, performance and productivity to a level not yet achieved and not imagined a decade ago. They will now provide almost unlimited control, monitoring, and visibility, giving users and manufacturers more data, and more analytic power to improve actionable decision making.

Many of these technologies have existed for years, but now thanks in part to advancements in wireless capabilities and cost of manufacturing, among other things, they are now taking hold in industrial, medical, and commercial applications. Learn how to use SMART human-machine interfaces to improve user experience.

Definition of Traditional HMI's

The SMART Human-Machine Interface (HMI) is the part of the machine that handles human interaction. The SMART HMI in a device is the user interface that provides control, monitoring, and visualization between a human and a device. This Includes taking inputs from sensors inside the device to trigger action.

Different Platforms & Types of HMI's

The definition of HMI's, Panel PCs and User Interfaces in general have changed over the last decade, however there are a few distinct differences.

- Custom Designed HMI Platforms: Most HMI's are proprietary requiring that hardware and software be developed by the HMI manufacturer to program, run, and operate the device. Here, a company typically needs to keep the overall cost of the device low due to the larger production quantities. It requires more up front work and development costs, however, the piece price at the production level is significantly lower. These typically include the integration of many cost effective User Interface components such as LCD's, mechanical switches, touch screens, capacitive membrane switches, luminescent backlighting just to name a few.

- Open HMI Platforms: Panel PCs are complete PCs and are open systems, meaning you can run anyone's software package designed to work with Windows and other popular open operating systems. This is more ideal for companies wanting to develop their own custom application software package to run a specific high value process. Because the PCs a rather costly, these usually are not cost effective in any application that requires more than a few pieces.

- Rugged HMI's: Designed to operate in challenging environments, such as hazardous areas and locations with harsh surroundings and extreme environmental conditions. Whether it is an a medical application where wash downs are required, to an aerospace design where the operating temperatures can reach both hot and cold extremes, HMI's can be manufactured to operate in most harsh environments.

Innovating Designs Meeting Necessary Specifications & Standards

Epec has an extensive set of tools for design, simulation, and testing. Offering a wide range of design, engineering and manufacturing capabilities, Epec provides custom integrated system design and development, including evaluation and analysis to several standards. Some of the key standards that Epec designs meet include automotive, military, marine, ISO, UL, CE, MIL, and/or customer specific applications. The combination of talented and highly trained design engineers and state of the manufacturing, allows Epec to deliver a world class product optimized for functionality and manufacturability.

Samplings Of Our HMI Capabilities Include:

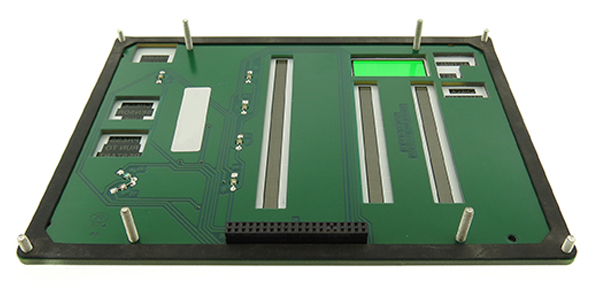

- Electronic Circuit Design: Analog circuits, digital circuits, mixed-signal circuits.

- PCB Design & Simulation Software: We have over 70 years of experience in PCBs.

- Embedded Logic and Signal Processing Board Design: RISC microprocessors or controllers, ARMs, DSPs, and FPGAs.

- LCD & Touch Screen Integration: To ensure superior performance and excellent color quality and imaging in a broad range of indoor and outdoor operating environments.

- Electronic Circuit Simulation and Analysis: Analog or digital electronic circuit simulators, and mixed-signal electronic circuit simulators.

- Enclosure Design: Enclosures to satisfy the customer's unique application and environment may include machined, cast, metal, and molded.

- System Drivers: BSP for a variety of hardware boards, including development/porting of the device drivers for various peripherals such as serial and Ethernet communication, graphics display, and touch screen.

- Interface Hardware Development: Membrane switches, graphic overlays, rubber keypads, joysticks, pushbuttons, audio controls, visual signals, and many others.

- System BIOS: BIOS flash is a tool that allows customers to update and backup the BIOS on hardware platforms.

- Operating System: Windows Embedded 8/7/XP/CE, embedded Linux, and QNX embedded solutions are total BSP to help customers speed up their project development.

- Embedded Firmware: A wide range of embedded firmware solutions, no-OS environment, straight code-to-hardware, hardware architectures: 8-bit, custom (optimized) 32bit processors.

- Application Programming Interface: A set of routines, protocols, and tools to build software applications.

- Detailed Drawings and Documentation: Packages developed and maintained using a PLM system to pass FDA and FAA certifications and inspections.

- 3D CAD/CAM: Used for the rapid creation of parts, assemblies, and prototypes along with simulation and design validation toolsets.

- In-House Prototyping Including 3D Printing: Can quickly produce designs for testing and validating form, fit and function to accelerate the time to market for our customers.

- Highly Accelerated Life Test (HALT): Using HALT stress testing methodology to accelerate product reliability testing during the engineering development process; cold step/hot step/rapid temperature cycling/stepped vibration (random)/combined environment stress (temperature cycling and random vibration plus power switching and power margining.

Designed Custom For Your Product Goals

There are many aspects to consider in the design and manufacturing of an SMART HMI for your device. The importance of each aspect should reflect the goals the product is designed to achieve. Our design team has worked on developing and manufacturing a variety of solutions for diverse categories, applications and market uses from complex, military qualified, ruggedized, to easy-to-use graphical user interfaces.

See this blog post to learn why custom smart interfaces are better than PLCs in many applications.

Also, don't forget to check out the smart HMI design to production timeline.

Harness the Power of SMART HMIs

Amplify operational efficiency and decision-making capabilities with Epec's state-of-the-art Human-Machine Interface solutions. Custom-built to meet your industry's unique challenges, our SMART HMI technology is your gateway to a new level of control and monitoring.

Request a Quote Request Design Support Request More Information