Manufacturing & Hardware Capabilities

Our user interface manufacturing facility located in New Bedford, MA features a full production factory, housed in a modern 52,000 square foot fully air conditioned environment.

We are equipped to handle all aspects of the manufacturing and test processes required to produce highly reliable custom user interfaces. Our capabilities support our vertically integrated manufacturing approach providing us with total quality control during all stages of product development.

Our in-house die-cutting capability provides great flexibility to produce custom assemblies tailored to meet virtually any requirement you may have. We have the necessary equipment to fully test all electrical and mechanical aspects of any human-machine interface we manufacture. Below you will find a list of our facility equipment.

Featured Manufacturing Equipment

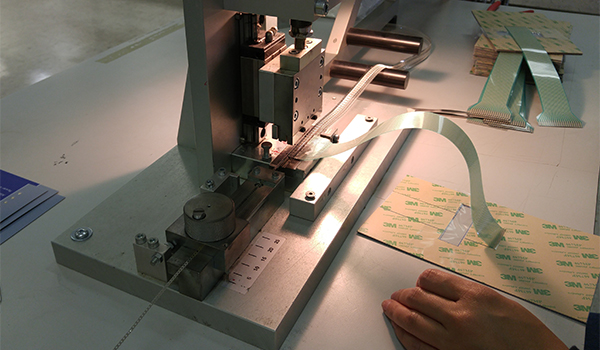

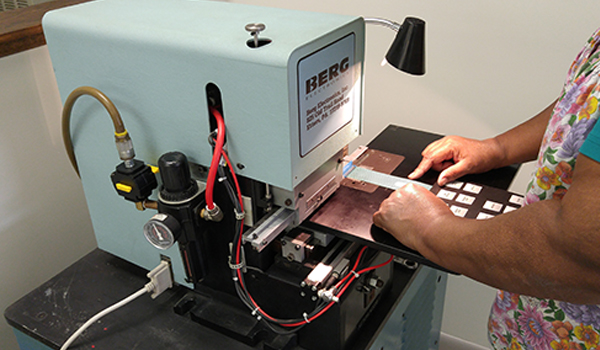

Nicomatic Crimpflex™ and Berg Clincher™ Connector Applicators

There are alternatives for the mating connector of your user interface. Both the Nicomatic Crimpflex™ and Berg Clincher™ connector applicators can provide a broad range of connector options. A full analysis of your requirements will be completed to provide you with a recommendation that best suits your application.

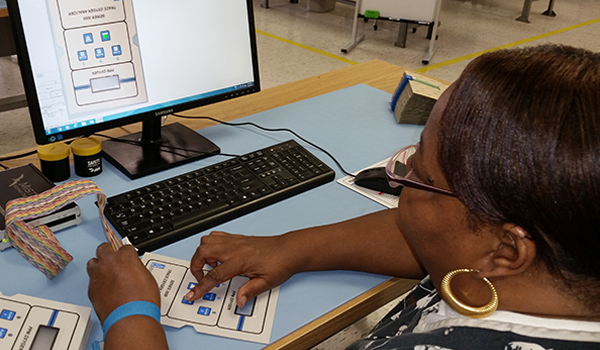

Mistral Keypad Test System

All user interface assemblies manufactured are 100% tested on a Mistral keypad test system. Electrical and mechanical parameters are tested. Electrical tests include switch resistance and bounce. Permanent connection resistance down to a milliohm and isolation resistance to 20M Ohms to an accuracy of +/-2%. The equipment measures LED forward voltage (turn-on state) and reverse leakage current (current present when an LED is in a reverse polarity state). The system is also capable of switch life cycle testing with full logging capability of test data which can be provided to customer by request.

Custom Designed Test Equipment

If required we have the capability to design and build custom test sets for certain products. Specifically, for certain high voltage motor controller applications that require to be run under load simulation. Whatever your test requirements are, we will work with you to ensure all products are 100% tested.

TestEquity 1007

The TestEquity 1007 cycling environmental chamber is used for certain high reliability applications to provide Environmental Stress Screening (ESS) capable of -73°C to +175°C temperature ranges. ESS is a proven method for eliminating latent defects in components to ensure military and aerospace customers receive only the most reliable, quality product. The equipment is certified by an A2LA accredited lab that is capable of meeting all testing requirements for military and aerospace applications that are exposed to harsh environments.

Thomson 90 Ton Clamshell Press

The Thomson press is used for die-cutting and embossing processes. In-house die-cutting and embossing capability is instrumental in supporting an aggressive delivery schedule. We have over 25 years of experience designing and manufacturing custom overlays and membrane switches for user interfaces. In that time we have designed more than 1,000 custom embossing and cutting dies.

Meiji Stereo Zoom Microscopes

The ability to solder the smallest surface mount technology (SMT) components by utilizing stereo zoom microscopes is available. The assembly team has been trained specifically in soldering techniques performed by this method. Operating under high magnification ensures that we produce high quality work for the smallest SMD components.

User Interfaces Tailored To Your Application

Experience the benefits of our fully-equipped, 52,000 square-foot facility in New Bedford, MA, for your custom user interface needs. Benefit from total quality control, advanced testing, and flexible connector options. Contact us now for a comprehensive solution tailored to your application.

Request a Quote Request Design Support Request More Information