User Interfaces with Molded Plastic Pushbuttons

Custom built user interfaces that incorporate molded plastic pushbuttons provide a high quality user operating surface along with core keyboard technology.

Depending on your end product needs, they can be encased in either a metal or molded plastic bezel or housing. This provides full support of all the major components used in the full user interface assembly.

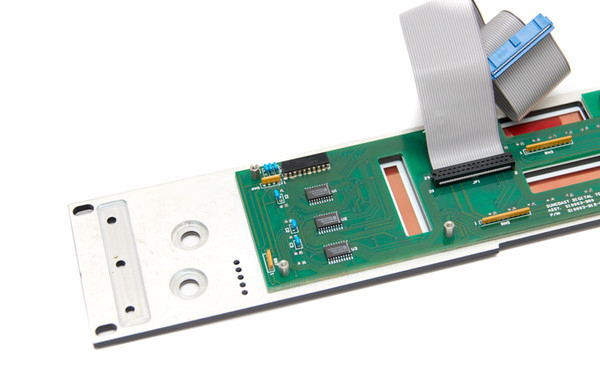

The above images illustrate a custom user interface subassembly using molded plastic pushbuttons for a unique 3-D operating surface with crisp tactile feel and metal support plate. There are virtually unlimited graphic overlay options available with your design. This complete user interface assembly uses rear-mounted electronics and full EMI shielding.

Additional Features & Options

- Uses gold plated, environmentally sealed switch surfaces for long mechanical and electrical switch reliability.

- Unambiguous tactile feel to the end user.

- Custom design and assembly processes ensure a desired fit and finish for aesthetic appearance by eliminating complex OEM subassembly processes, insuring the integrity of subassembly for a bolt-on, plug-in final assembly.

- RFI/EMI/ESD shielding options can be added to the subassembly if needed.

- Wide variety of soldered connector options and electronic components can be mounted on the rear side of the circuit board.

- Mechanical parts such as chassis handles, rotary controls can be added.

- High power discrete switches and through hole RF connectors can mount directly to the subassembly.

Revolutionize Your User Experience with Our Custom-Built Interfaces

With gold-plated, environmentally sealed switches and a 3D tactile feel, we ensure long-lasting reliability and unambiguous user feedback. Simplify your OEM processes with our bolt-on, plug-in solutions designed for optimal fit and finish.

Request a Quote Request Design Support Request More Information