Material and Plating Options

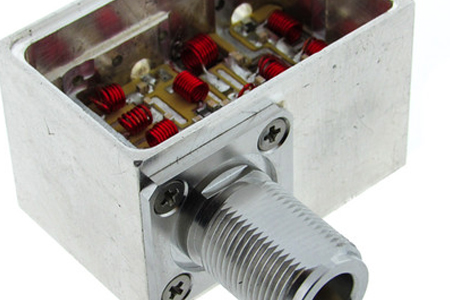

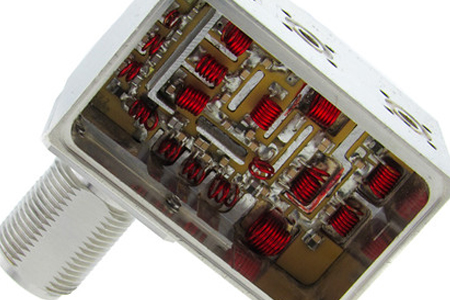

When designing broadband high frequency radio frequency (RF) devices, low loss and high loss are critical elements. Ultimately the goal is to develop excellent solderable surfaces with high corrosion resistance and superior electrical and thermal conductivity.

While silver is the most electrically conductive material available, there are several plated finishes suitable for PCBs and mating materials.

Plating Finishes Include:

- Immersion Silver

- Immersion Gold

- Electrodeposited Silver with Copper Strike and Underplated Electroplated Nickel

- Electroless Nickel

- Electroless-Nickel-Immersion-Gold

- Electroless Nickel

- Chromate Conversion

Advantages of Plating Finishes for Radio Frequencies

Transmission lines and interfaces formed from copper offer excellent conductivity but do not offer protected solderable surfaces. PCB finishes are less conductive than the copper conductors bonded on the substrates and will suffer more loss than the bare copper, especially at higher frequencies.

Conductor Losses Are Frequency Dependent:

- RF transmissions at higher frequencies create a skin effect and the signal tends to travel on the surface.

- RF transmissions at lower frequencies, the current will use more of the conductor.

- Signal loss rises when the current uses less of the conductor, and because of this effect at higher frequencies, plated finishes can have greater impact on PCB insertion loss at higher frequencies.

- All of this tends to translate to the grounding effects of the plated finishes of the materials the PCB is mated to and other associated components.

Selective Plating

Selective plating can be utilized to apply a layer of gold to unsoldered surfaces and plated thru holes while allowing silver to be applied to all other surfaces. This is an expensive option but is a crucial performance driver when required.

While gold is an excellent conductor solder embrittlement can occur when it is absorbed as components are soldered the PCBs conductive traces.

All of these finishes should be considered in your RF product design as well as construction materials that achieve light weight, structural integrity and thermal efficiency:

- Aluminum

- Stainless Steel

- Brass

- PTFE (polytetrafluoroethylene)

- Solder Types

- Epoxy Types

Let Our Team Help You with Your RF Design

Our Engineering team considers all of these plating and material options from the initial renderings through the DFM process leading to final design of your RF product. Request a Free Quote Now!