RF Product Capabilities

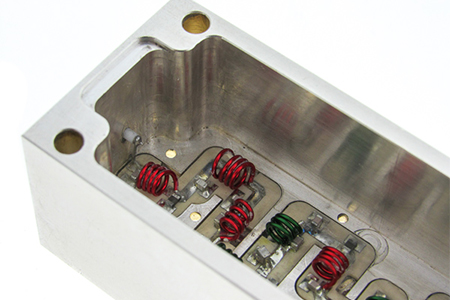

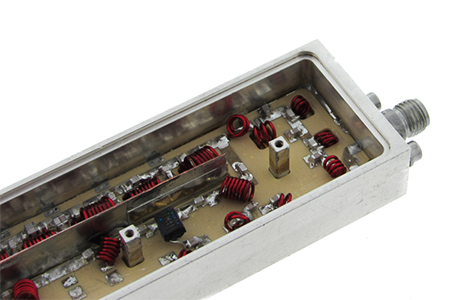

Epec Engineered Technologies designs and manufactures a full line of RF coaxial cables and microwave filters, duplexers, including lumped element, cavity, and tunable filters. The solutions we provide cover frequencies from 1 MHz to 26 GHz and can range in bandwidths from 0.1% to greater than 150%.

RF Filters are a critical component of any communication system and their main function is to enable required signals to pass through the circuit at defined frequencies and reject those that are not wanted. By filtering out unwanted signals from entering a system, an RF filter will eliminate any potential interference. With the increase of wireless devices in every industry, filters used to minimize interference are an important design attribute of every system.

Our Strength

Our strength and experience is in working with the largest and most sophisticated designs for applications that include telemetry, up/down converters, combining or splitting base stations, connections to a common antenna, and many more. Because we have invested and developed in house design, production and testing processes, we manufacture proven and innovative designs that guarantee the highest reliability and exceptional product performance.

Technical Expertise

The custom RF products that Epec designs and manufactures cover frequencies from 1 MHz to 26 GHz and can range in bandwidths from 0.1% to greater than 150%. Because of such broad ranges of frequency and bandwidth, there is no single technology that will fit every application which requires Epec to maintain a staff of design and applications engineers/technicians with to an extensive design library and application experience.

Specialized equipment and software, including high-frequency devices and 3D modeling software, assists with the design as most of these products are high selectivity, low loss, and have a smaller footprint than conventional designs. The majority of our custom designed products are manufactured in machined housings that are individually designed to accommodate the unique mechanical specifications of a customer's requirements.

Manufacturing History

Epec was one of the pioneers in the Printed Circuit Board industry in the United States having begun production in 1952. That expertise is the basis for our filter business as every RF product is based and founded on a printed circuit board. Our lean manufacturing focus and our state of the art ERP system allows us to quickly move from prototype to production while maintaining data integrity, traceability, and consistency.

Investment in our ISO 9001:2008 state-of-the-art manufacturing facility in New Bedford, MA with on-site ESS chambers, and a fleet of network analyzers support efficient flow of product to meet delivery deadlines. As a standard practice Epec applies soldering and workmanship practices that conform to military standards and American National Standards Institute (ANSI) standards, as all of our soldering technicians are certified to IPC J-STD-001 and IPC-A-610.

Speed is Key

As a designer and manufacturer of custom RF products, we understand that our customers need their suppliers to respond quickly as time to market is critical for success for our OEM's. Epec has a long history of providing rapid design and development services for all of our product lines and RF products are no different. Quickly defining the appropriate configuration, the best materials, and all of the other key elements in the design are critical to a successful prototype launch that gets our customers product quickly to prove out the end product.

Engrained Quality

Workmanship is a priority at Epec, and we believe that you can have world class quality and move quickly. Having years of expertise in developing processes that allows us to quickly over from NPI into production allows our customers the peace of mind that all of the critical parameters have been documented and implemented for their design. Our facility is certified to and has passed the most rigorous of audits including being Navy Flight Hardware approved as we take pride in our ability to provide our armed forces with the most technically advanced solutions in the world.

Utilizing lean manufacturing with visual management controls and ISO based quality systems from engineering design to manufacturing ensures that engrained quality of the products and the rapid response to customers' needs.