Time Versus Temperature

Time versus temperature is an important consideration when using polyimide flexible heaters, as the relationship between the two directly affects the efficiency and effectiveness of the heating process. Polyimide is a type of flexible polymer that is commonly used as a substrate material for flexible heaters, flexible printed circuit boards, and high-temperature tapes. It is known for its high thermal stability, chemical resistance, and mechanical flexibility, making it an ideal material for heating applications, especially where the object to be heated is in a tight space or requires a focused heating area.

Flexible heaters are thin, flexible, and electrically conductive devices that are designed to generate heat when an electrical current is passed through them. They typically consist of a thin, flexible substrate (such as polyimide or silicone), a heating element (such as a metal or metal alloy; Inconel for example), and electrical leads. The heating element is imaged and etched into the substrate where electrical leads are attached, creating a circuit. When an electrical current is passed through the circuit, the heating element resistance generates heat through a process known as Joule heating. This heat can then be transferred to the surface to be heated.

Temperature Stability

The temperature stability of a polyimide flexible heater is also important, as fluctuations in temperature can negatively affect the heating process. To maintain a stable temperature, flexible heaters are often equipped with temperature control mechanisms, such as thermistors or Resistance Temperature Devices (RTDs), to regulate the electrical power applied to the heating element. This helps to prevent overheating and maintain a consistent temperature.

In a polyimide flex heater, the time required to reach a certain temperature is directly related to the amount of electrical power applied. The electrical power is determined by the current, voltage, and resistance of the heating element, which in equation form is known as Ohm’s Law. See our blog post on Ohm’s Law for more information.

Power and Heat

When higher electrical power is applied, the heating element will generate more heat, and the polyimide substrate will reach the desired temperature more quickly. However, care must be taken to ensure that the heating element does not generate too much heat, as this can cause the polyimide substrate to break down and become damaged.

The temperature of the polyimide heater is also affected by the thermal conductivity of the substrate and the surrounding environment. The thermal conductivity of polyimide is relatively low, so it can take longer for heat to be transferred from the heating element to the surface to be heated. In some cases, it may be necessary to incorporate thermal transfer materials, such as metal foils, thermally conductive adhesive, or thermal grease, to improve the thermal conductivity of the system and reduce the time required for the heater and then the device to be heated to reach the desired temperature.

Flexible Heater Size and Shape

Flexible heaters can be shaped, formed, and cut to fit a variety of applications, making them a versatile solution for heating tasks.

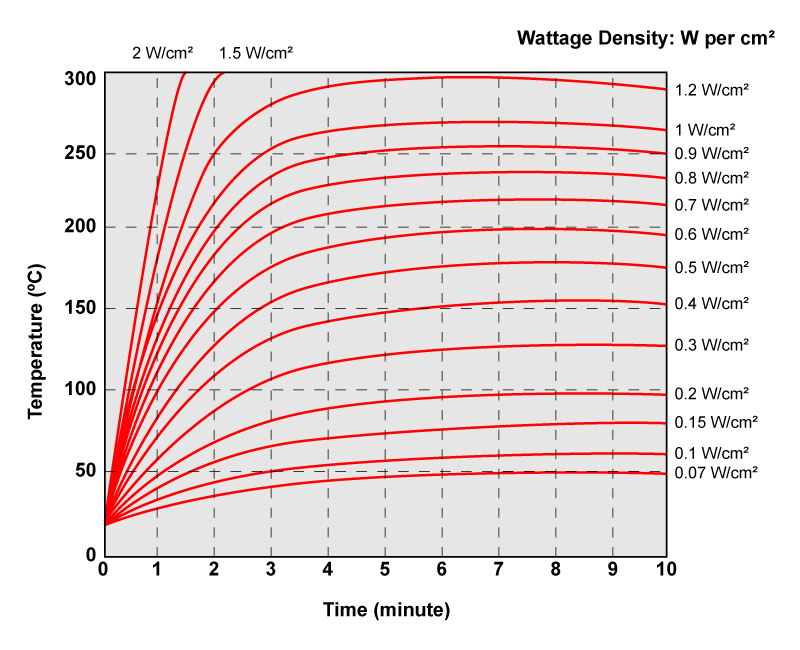

The time it takes for a flexible heater to reach 200°C depends on several factors, including the type of heater, its size, the electrical power applied, and the thermal conductivity of the substrate and the surrounding environment. As a rough estimate, it can take anywhere from a few seconds to several minutes for a flexible heater to reach 200°C. However, without knowing the specific design, power supply, and environmental conditions, it is difficult to provide a more accurate estimate.

As a point of reference, you can see the graph below, which gives you a basic overview of how long it will take the heater to get to a certain temperature based on the watt density of the material.

Time vs. Temperature - Wattage Density Chart

The relationship between time and temperature in a polyimide flexible heater is complex and dependent on several factors, including the electrical power applied, the thermal conductivity of the substrate and surrounding environment, and the temperature control mechanisms in place. Proper consideration of these factors is critical for ensuring an efficient and effective heating process with a polyimide flex heater.

Maximize Efficiency with Polyimide Flexible Heaters!

Polyimide, known for its thermal stability and flexibility, is the top choice for precise heating tasks. With our heaters, you get consistent temperature control, adaptable designs for tight spaces, and quick and efficient heat distribution.

Request a Quote Request Design Support Request More Information