Temperature Sensors Used in Flexible Heaters

Thermocouples, Resistance Temperature Detectors (RTDs), and thermistors are all types of temperature sensors that can be used in flexible heaters to measure the temperature of the heater surface or the surrounding environment. Below is a brief explanation of each type of sensor. Check out these important temperature management and safety protocols for flexible heaters.

Thermocouples

A thermocouple consists of two wires made of different metals that are joined together at the sensing end. When the temperature changes, the thermocouple generates a small voltage that is proportional to the temperature difference. Thermocouples are simple, rugged, and can measure a wide temperature range, but may require calibration and can have a non-linear response. Thermocouples are commonly used in flexible heaters for temperature sensing and control.

Here are some of the Best Mechanisms to Control Flexible Heater Temperatures.

Reasons why thermocouples are used in flexible heaters:

- Wide temperature range: Thermocouples can measure a wide range of temperatures, from cryogenic (-200 °C) to high temperature (>2000 °C), making them suitable for a variety of heating applications.

- Fast response time: Thermocouples can detect temperature changes quickly, in a matter of milliseconds, allowing for rapid feedback and control of the heater output.

- Rugged and durable: Thermocouples are simple in design, with no moving parts or fragile elements, making them reliable and long-lasting. They can withstand vibration, shock, and moisture, which are common in many industrial and outdoor environments.

- Self-powered: Thermocouples generate a voltage signal that is proportional to the temperature difference between the sensing end and the reference end, so they do not require external power or amplification. This makes them easy to install and operate, without the need for additional wiring or components.

- Interchangeable: Thermocouples are standardized according to the combination of metals used, such as Type K (chromel/alumel) or Type J (iron/constantan), so they can be easily replaced or calibrated if needed.

RTDs (Resistance Temperature Detectors)

An RTD is a temperature sensor made of a metal wire or film that changes resistance with temperature. The most common type of RTD is made of platinum wire, which has a linear resistance-temperature relationship. RTDs are accurate, stable, and can measure a wide range of temperatures, but may be more expensive and fragile than other sensors. RTDs are used in flexible heaters because they provide accurate and stable temperature measurements over a wide range of temperatures. They are made of a metal wire or film that changes resistance with temperature, and the most common material used for RTDs is platinum. Platinum RTDs have a linear resistance-temperature relationship and are known for their high accuracy and repeatability.

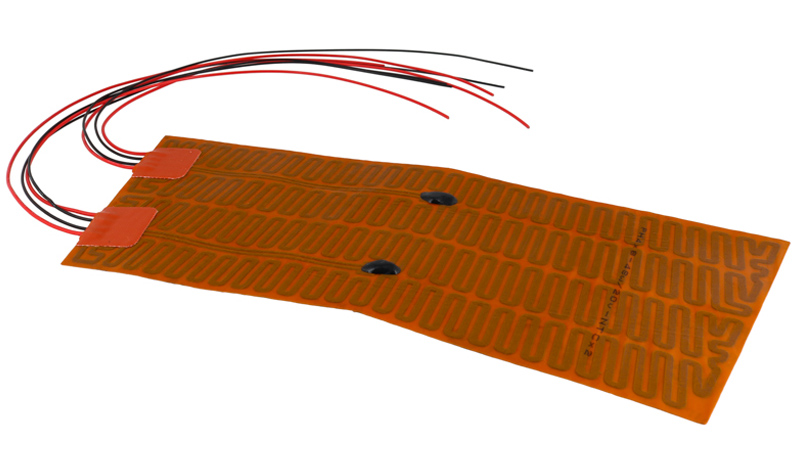

In a flexible heater, an RTD can be embedded in the heating element or attached to the surface of the heater to measure the temperature. The RTD converts the temperature into an electrical signal, which can be used by a controller or a thermostat to regulate the heater's power output. It can also provide feedback on the temperature distribution across the heater, which can help optimize the heater's performance and energy efficiency.

Compared to other temperature sensors such as thermocouples or thermistors, RTDs have several advantages in flexible heaters:

- Accuracy: RTDs have a high level of accuracy and repeatability, typically within ±0.1°C or better.

- Stability: RTDs have good long-term stability and can maintain their calibration over time.

- Linearity: RTDs have a linear resistance-temperature relationship, which makes them easy to calibrate and use with electronic circuits.

- Range: RTDs can measure a wide range of temperatures, typically from -200°C to +850°C.

- Compatibility: RTDs can be used with various types of flexible heater materials and designs.

Thermistors

A thermistor is a temperature sensor made of a semiconductor material that changes resistance with temperature. Thermistors are typically made of metal oxides or ceramics and can have a negative or positive temperature coefficient of resistance. Negative temperature coefficient (NTC) thermistors have a higher resistance at low temperatures and are more sensitive, while positive temperature coefficient (PTC) thermistors have a higher resistance at high temperatures and are more stable. They are low-cost, accurate, and have a fast response time, but may require calibration and have a limited temperature range.

Thermistors are often used in flexible heaters for temperature sensing and control. Thermistors are temperature-sensitive resistors made of ceramic or polymer materials that change their resistance with temperature. They have a highly predictable and nonlinear resistance-temperature relationship, which makes them suitable for accurate temperature measurement and control.

Reasons why thermistors are used in flexible heaters:

- High sensitivity: Thermistors have a high sensitivity to temperature changes, which means they can detect even small temperature variations. This makes them ideal for applications that require precise temperature control, such as in medical equipment, laboratory instruments, and aerospace systems.

- Fast response time: Thermistors have a fast response time, which means they can quickly detect and respond to temperature changes. This is important in applications where rapid temperature changes can occur, such as in semiconductor processing or thermal cycling.

- Compact size: Thermistors are small and lightweight, which makes them suitable for use in compact and portable devices. They can be easily integrated into flexible heaters, without adding extra bulk or weight.

See our blog post on The Pros and Cons of Temperature Sensors for more information.

Elevate Your Heating Solutions with Advanced Temperature Sensors!

Harness the precision of Thermocouples, RTDs, and Thermistors in flexible heaters. Experience accurate temperature measurements, rapid feedback, and optimal energy efficiency. Choose the right sensor for your unique needs and achieve unparalleled temperature control.

Request a Quote Request Design Support Request More Information