Flex Heater Design: Shape and Size

When determining your flexible heater needs, let us help navigate you through all the different attributes and design options. By working with your design engineers, we can help you create a custom product that’s specific for your application needs. Check out these tips for designing flexible heaters for cost-effective manufacturing.

Designed To Fit Your Application

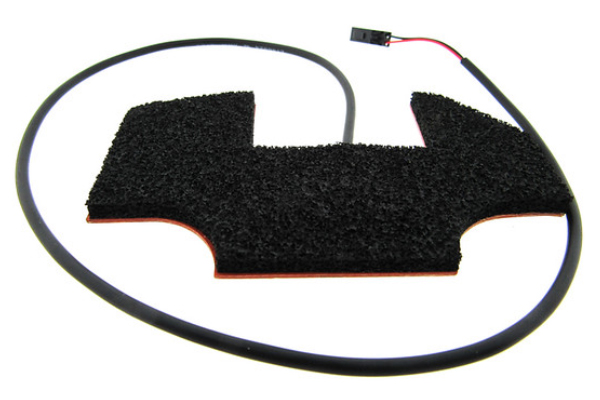

The size and shape of your custom flexible heater will be determined by your final application. Standard shapes are square, rectangular, or round but any shape desired can be custom designed and produced to meet your electrical and thermal performance requirements. Most size, shape or contour can be used to apply direct and efficient heat without decreasing reliability.

We utilize state of the art capabilities such as laser cutting of outlines, allow us to offer endless shape configurations with tight dimensional tolerances with all our flexible heater products.

Variety Of Geometries

Flexible heaters can be manufactured in a variety of geometries to fit specific heating requirements.

Most common geometries of flexible heaters include:

- Rectangular or square-shaped heaters

- Circular heaters

- Triangular or diamond-shaped heaters

- Thin, narrow, or long heaters

- Custom-shaped heaters designed to fit specific equipment or machinery.

- Multi-zone heaters with different temperature zones across the surface of the heater. Multizone flexible heaters are a type of heating system that is designed to be adaptable and customizable. These heaters consist of multiple heating zones that can be independently controlled, allowing users to adjust the temperature in different areas of the heater as needed.

- Heaters with cutouts for sensors, cables, or other components. Several types of sensors can be used with flexible heaters, depending on the specific application requirements. The type of sensor used with a flexible heater will depend on the specific temperature range, accuracy, and response time requirements of the application.

- Holes can be placed in flexible heaters for a variety of reasons, such as to accommodate mounting points, sensors, or other components. These holes can be created using methods such as punching, drilling, or laser cutting.

The choice of geometry will depend on the heating application, available space, and other factors such as the desired wattage density, temperature range, and operating conditions.

Craft the Perfect Heating Solution with Our Expertise!

Navigating the world of flexible heaters can be challenging. Let our team work side by side with your engineers to tailor-make a heater solution that's optimal for your specific application. Whether it's standard shapes or unique geometries, laser-cut precision or multizone temperature controls, we've got the expertise and technology to bring your vision to life. Don't settle for off-the-shelf. Let's co-design the ideal flexible heater for your needs. Engage with our team today!

Request a Quote Request Design Support Request More Information